Workpiece machining equipment and process for assembling hardware and sealing ring

A technology for processing equipment and hardware, applied in the field of post-processing equipment for injection molding workpieces, and can solve problems such as poor workpiece consistency, inability to meet production requirements, and low assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

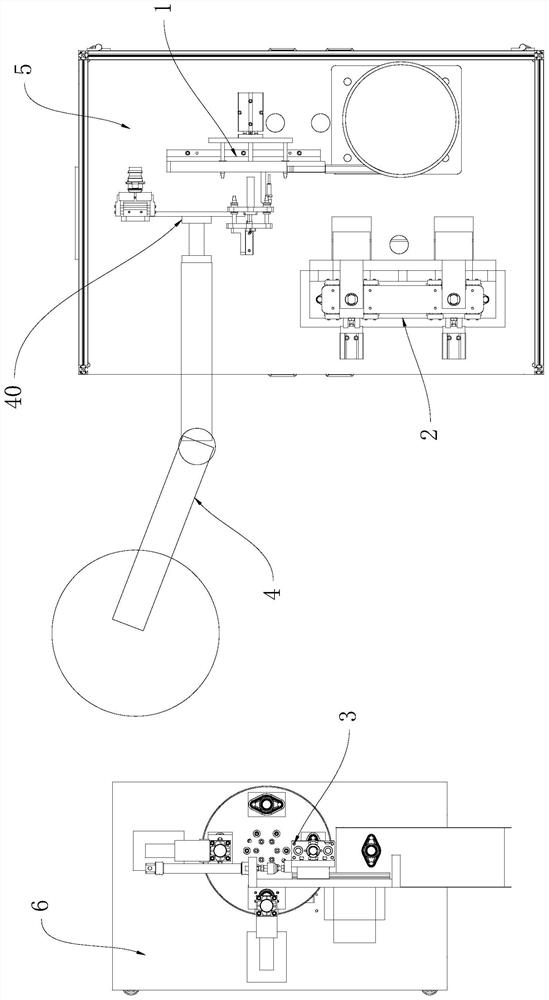

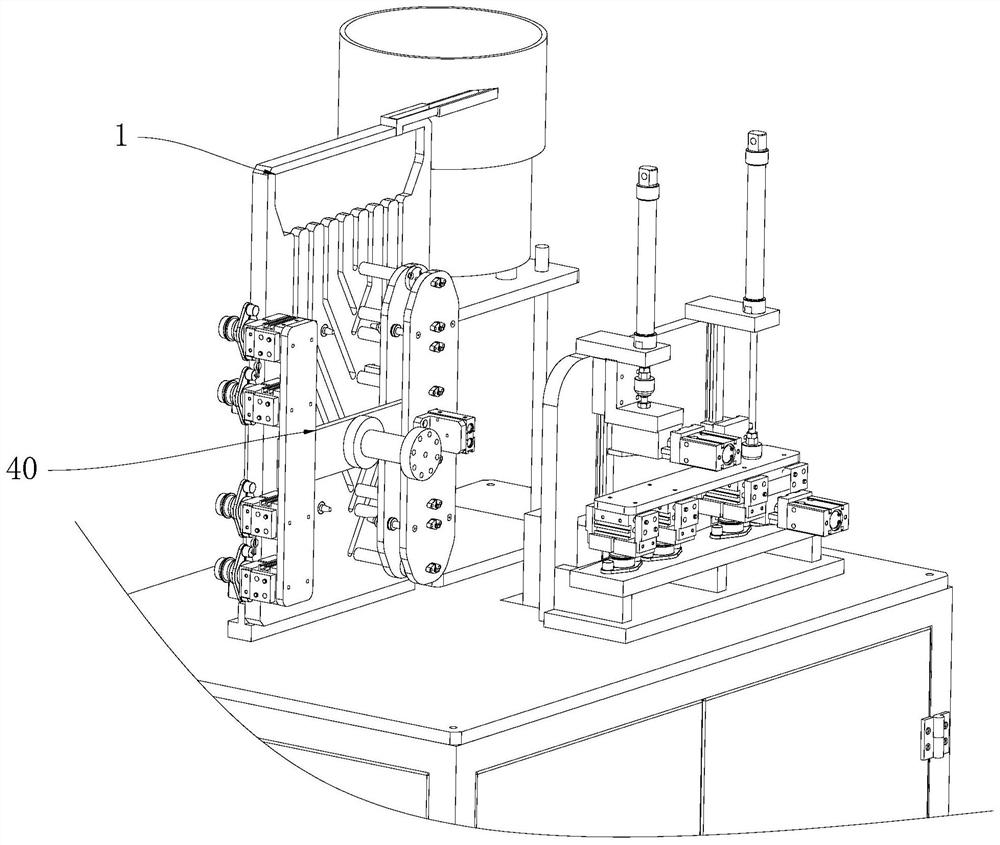

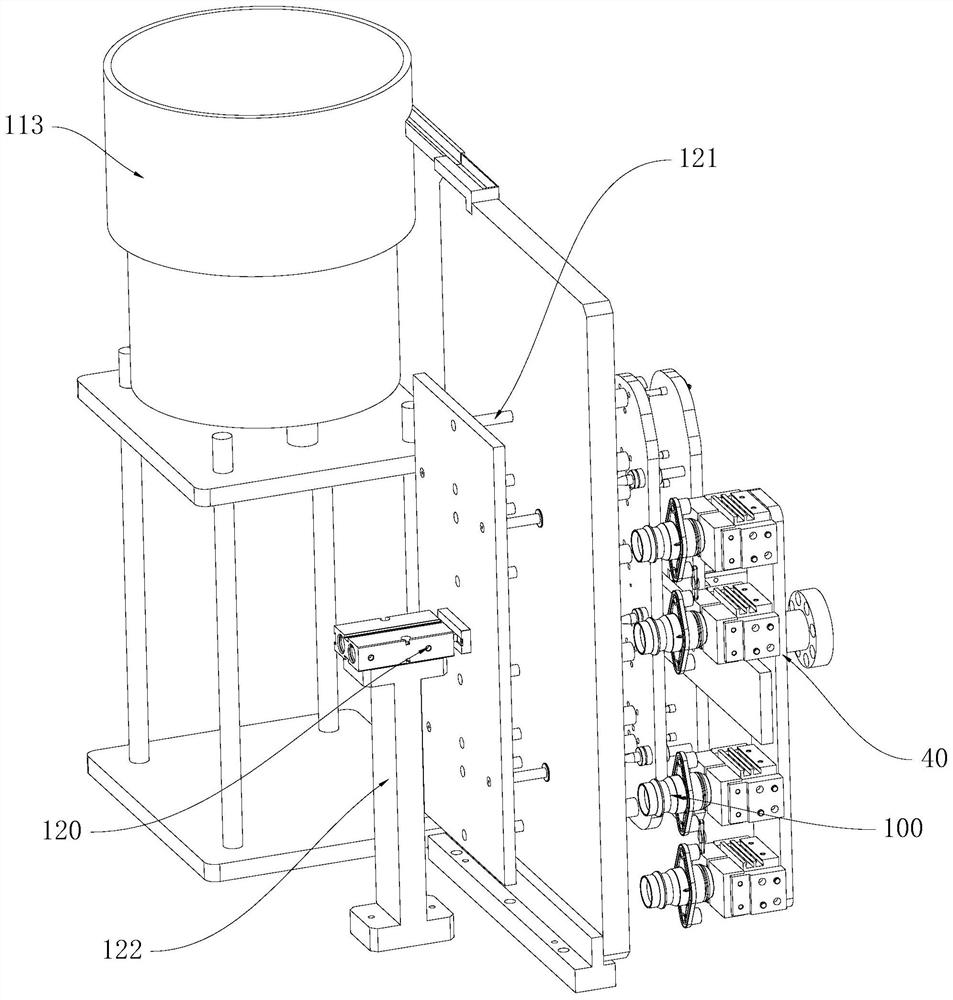

[0031] This embodiment proposes a workpiece processing equipment for assembling hardware and sealing rings, combining Figure 1 to Figure 5 As shown, it includes a hardware straight-in device 1, a water cut device 2, a sleeve sealing ring device 3 and a multi-axis robot 4, and the end of the multi-axis robot 4 is provided with a manipulator device 40 for picking up a workpiece 100, wherein:

[0032] The multi-axis robot 4 is used to drive the manipulator device 40 to move, so that the manipulator device 40 sequentially transfers the workpiece 100 to the hardware straight-in device 1, the water cutting device 2 and the sleeve seal ring device 3;

[0033] The hardware straight-in device 1 is used to put hardware straight into the workpiece 100 picked up by the manipulator device 40;

[0034] The water cutting device 2 is used to cut off the water nozzle 101 connected between two adjacent workpieces 100;

[0035] The sealing ring assembly device 3 is used for fitting the sealin...

Embodiment 2

[0054] In practical applications, after the injection molding workpiece is formed, there is a connecting nozzle between each two workpieces. In the later processing, the nozzle needs to be removed. However, the existing method of cutting the nozzle is generally cut manually with corresponding tools, resulting in the removal of the nozzle. The flatness and consistency of the position are not good, which affects the product quality of the workpiece, and also has high labor costs.

[0055] In this regard, this embodiment proposes a nozzle device for injection molded workpieces, which combines Figure 6 to Figure 10 As shown, the water notch device 2 includes a water notch support 20, a lifting plate 21 and a lifting mechanism 22 for driving the lifting plate 21 to rise or fall, and the notch support 20 is used to place a plurality of The workpiece 100, the lifting plate 21 is located above the nozzle support 20, the bottom of the lifting plate 21 is provided with a plurality of p...

Embodiment 3

[0063] In practical application, for some injection molding workpieces that need to be assembled with sealing rings, it is necessary to manually set the sealing rings on the injection molding workpieces manually. This kind of socketing method is not only inefficient, but also easily causes sealing The sealing ring is damaged, resulting in insufficient sealing performance of the product. In addition, due to the lack of a sealing ring detection mechanism, it is easy to have misfits, missing sealing rings, etc., resulting in insufficient assembly quality and unable to meet production requirements.

[0064] In this regard, this embodiment proposes a sealing ring device for injection molded workpieces that can improve the assembly quality of the sealing ring, has a sealing ring detection function, can improve production efficiency, and save labor costs. Figure 11 to Figure 13 As shown, the sleeve sealing ring device 3 includes a rotary table 30, a sealing ring pressing mechanism 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com