Material tank transfer device for cosmetic production workshop

A production workshop and transfer device technology, applied in chemical/physical processes, transportation and packaging, chemical instruments and methods, etc., can solve problems affecting the production quality of cosmetics, poor cosmetic preservation effect, and poor material protection effect, etc., to increase Post-processing quality, novel design, ensuring the effect of movement and fixed action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

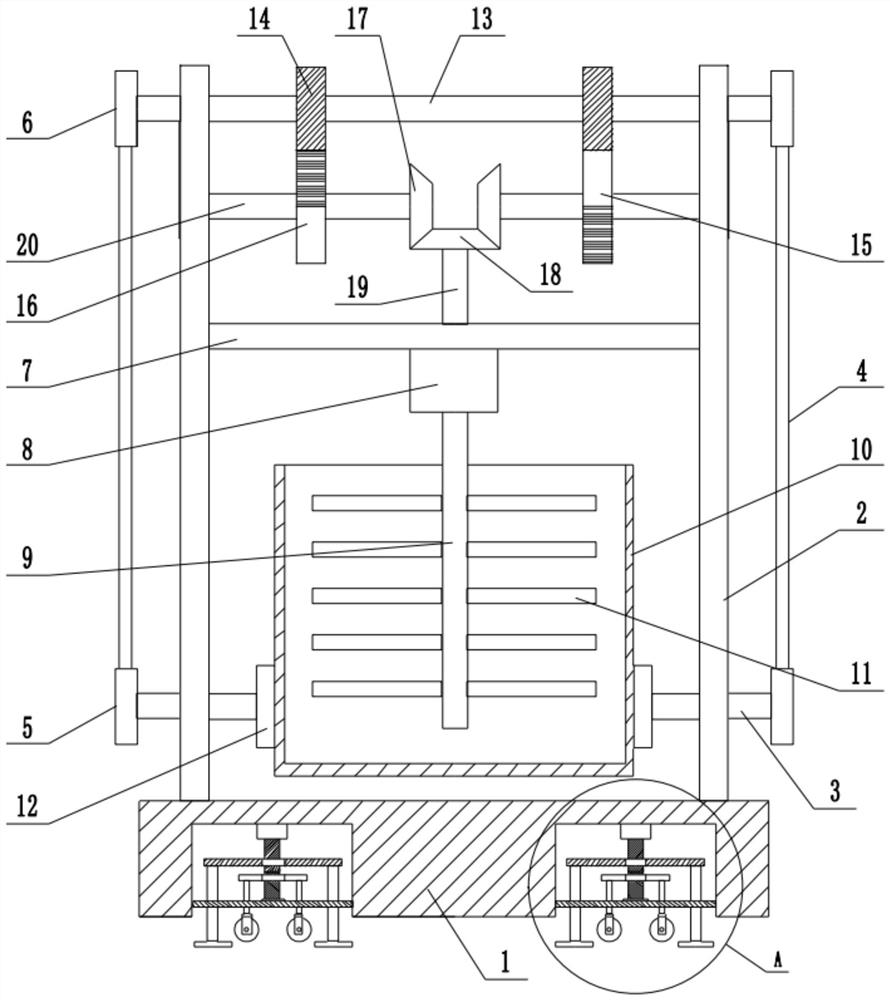

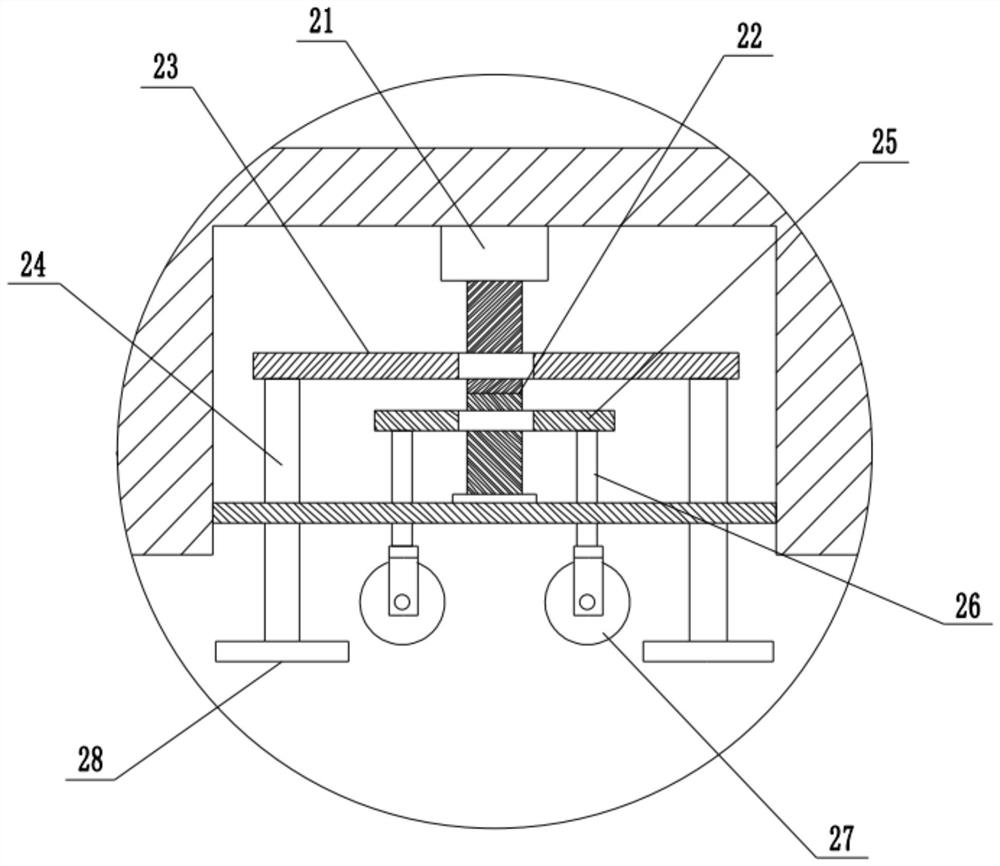

[0028] Referring to the figure, in an embodiment of the present invention, a material tank transfer device for a cosmetics production workshop includes a fixed base 1, a support frame 2 is installed on both sides of the upper end of the fixed base 1, and a fixed plate 7 is installed between the middle parts of the support frame 2 , the middle part of the fixed plate 7 is fixed with a biaxial motor 8, so that the upper output shaft 19 and the lower output shaft 9 can be driven to rotate simultaneously, a rotating shaft 13 is installed between the upper ends of the support frame 2, and a rotating gear 14 is installed in the middle of the two ends of the rotating shaft 13, The lower end of the rotating gear 14 is intermittently meshed with a left gear 16 and a right gear 15, and the outer sides of the left gear 16 and the right gear 15 are provided with a half circle of teeth, thereby ensuring that only one of the left gear 16 and the right gear 15 can be matched with the correspon...

Embodiment 2

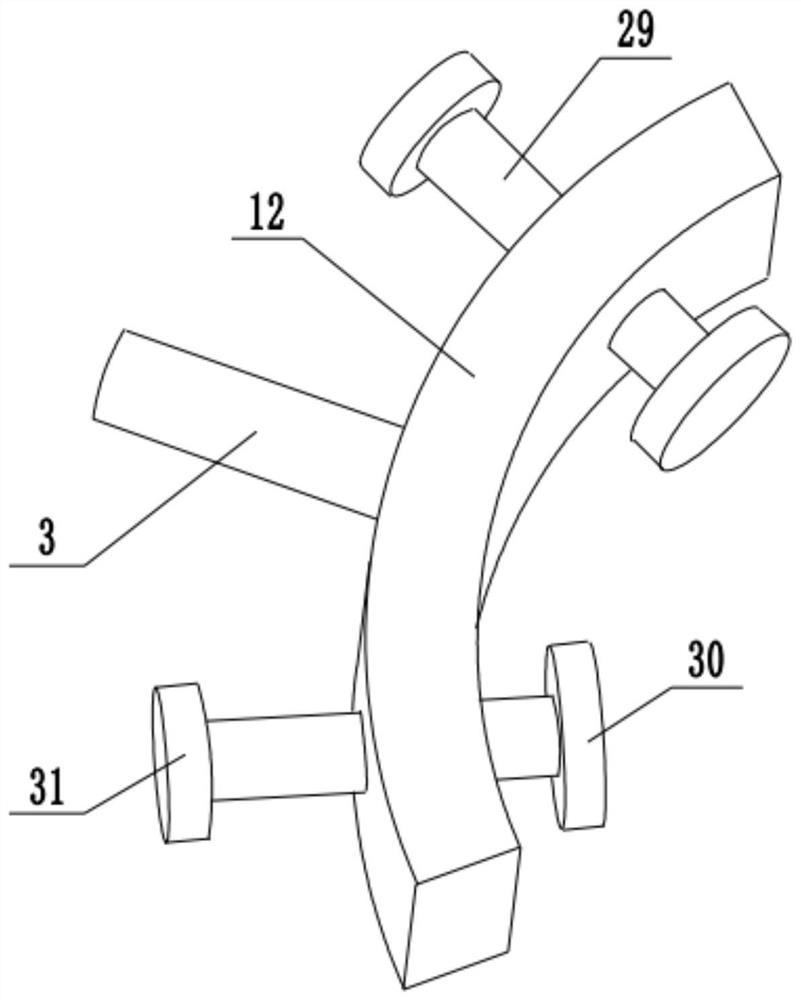

[0031] refer to image 3 , in another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that a tank body 10 is arranged between the fixed rings 12, threaded columns 29 are respectively installed in the front and rear middle parts of the fixed rings 12, and the threaded columns A clamping block 30 is installed at the inner side of 29, and an adjusting block 31 is installed at the outer end of the threaded column 29. By setting the adjusting block 31, the threaded column 29 is rotated, so that the clamping block 30 clamps and fixes the corresponding tank body 10.

[0032]In the present invention, when working, the material tank that needs to be transferred is placed between the fixed rings 12, and the biaxial motor 8 is started at the same time, so that the biaxial motor 8 drives the output shaft 9 to rotate on the one hand, and the tank body is mixed under the action of the mixing blade 11. The material is stirred....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com