Reinforcing and limiting structure and method for detachable suspension of trailer

A technology of limit structure and trailer, which is applied in the substructure, tractor-trailer combination, suspension, etc., can solve the problem of easy breakage of the suspension connection structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

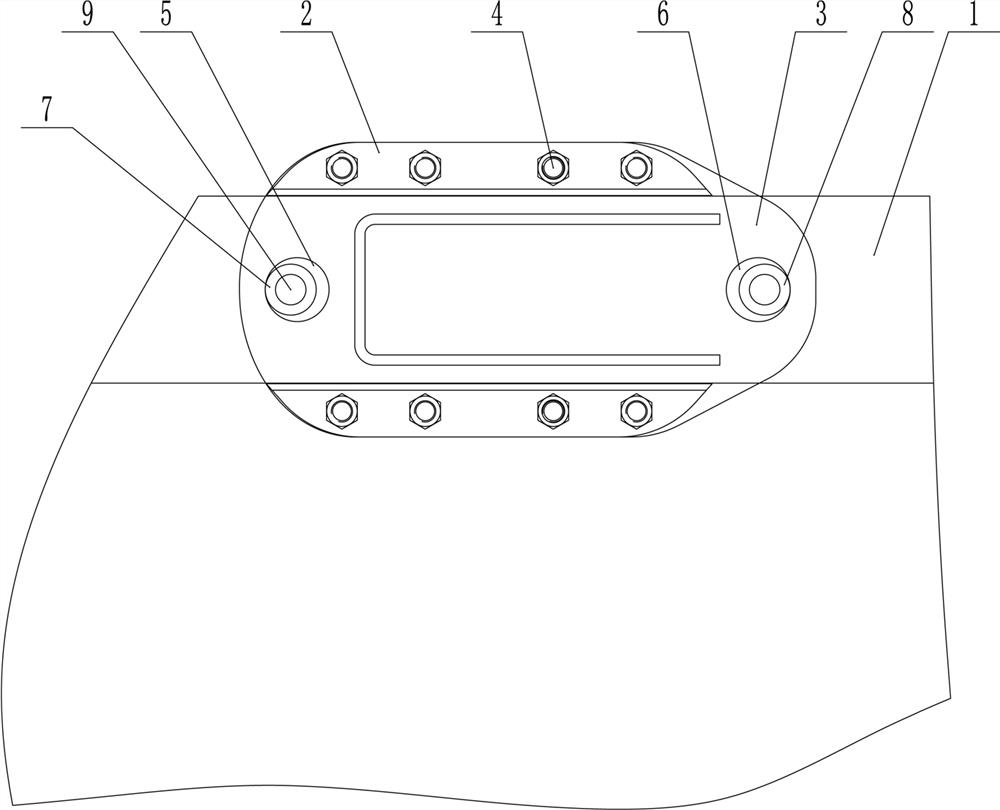

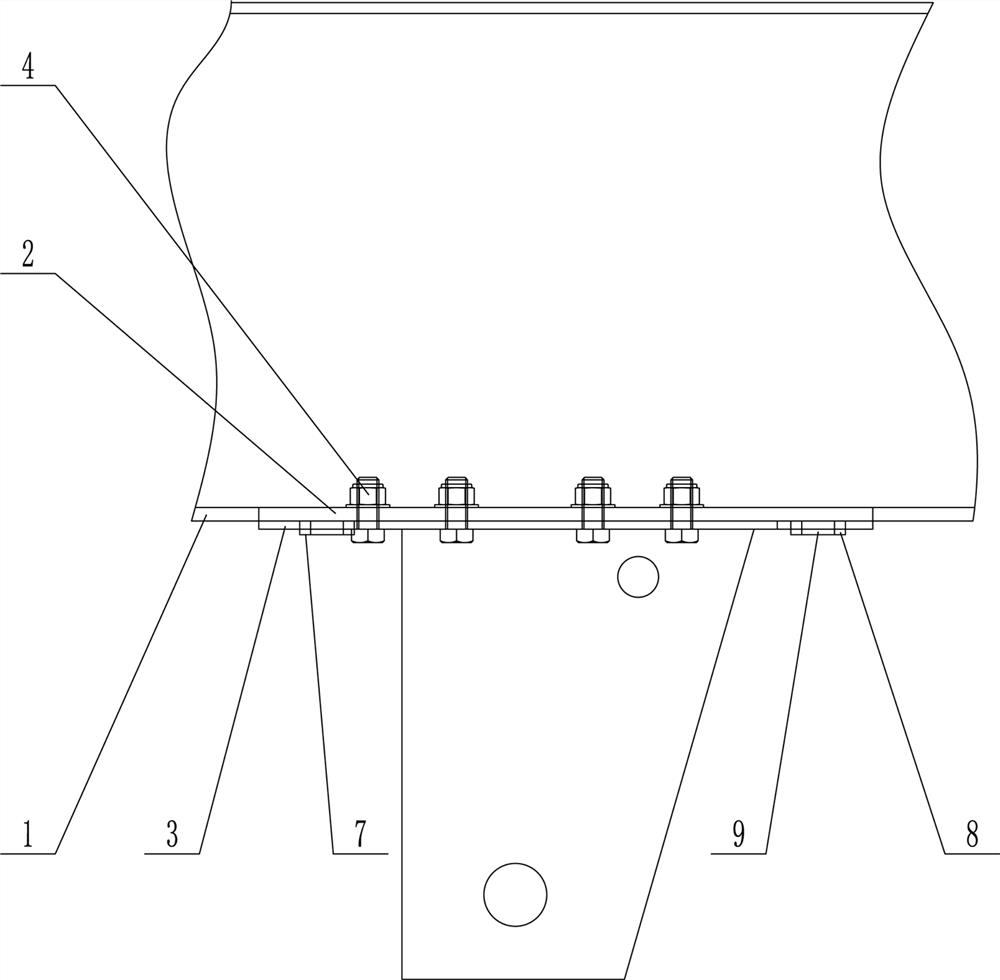

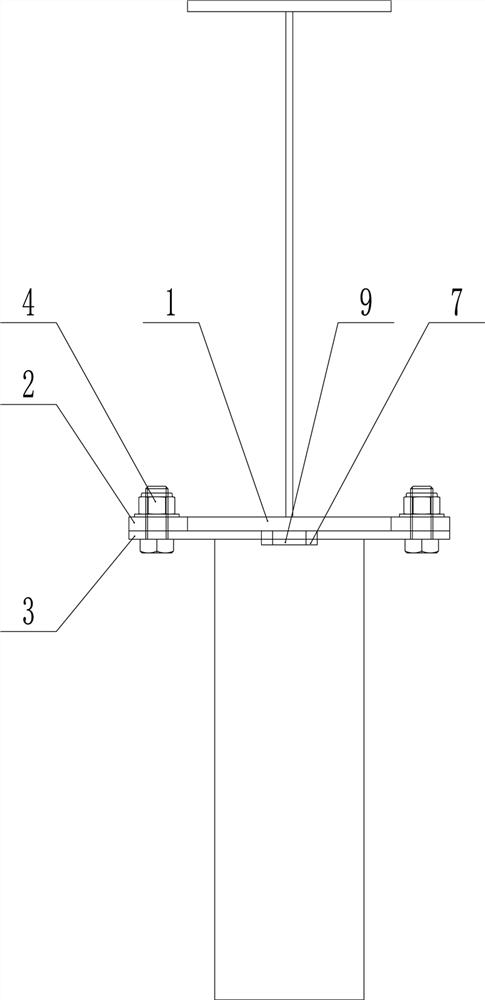

[0034] Such as Figure 1-Figure 5 As shown, a reinforcement and limit structure for a detachable suspension of a trailer, including a lower wing plate 1, a widened plate 2, a connecting hole on the widened plate, a suspension connecting plate 3, a front limit hole 5, and a rear limit Hole 6, circular front limiting plate 7 and circular rear limiting plate 8.

[0035] The connecting hole of the lower wing plate is provided on the suspension connecting plate, and the connecting hole of the lower wing plate corresponds to the connecting hole on the widening plate and is connected by bolts 4 .

[0036] The front limiting hole 5 is arranged at the front of the suspension connecting plate 3 , and the rear limiting hole 6 is arranged at the rear of the hanging connecting plate 3 .

[0037] The front limiting plate 7 is installed corresponding to the front limiting hole 5, the bottom end of the front limiting plate 7 is welded and fixed to the lower wing plate 1, and the rear limitin...

Embodiment 2

[0045] The difference between this embodiment and Embodiment 1 is that when the front and rear two limit plates are of other shapes, the front limit plate is welded and fixed to the lower wing plate through the rear bottom seam, so that the weld remains at the front limit. The rear side of the position plate, the front side of the front limit plate is in close contact with the inner edge of the front limit hole; the rear limit plate is welded and fixed to the lower wing plate through the front bottom seam, so that the weld The front side of the rear limiting plate is left, and the rear side of the rear limiting plate is in close contact with the inner edge of the rear limiting hole.

Embodiment 3

[0047] The difference between this embodiment and Embodiment 1 is that both the front limiting plate and the rear limiting plate are polygonal plates with welding process holes in the center, and the front limiting hole and the rear limiting hole Both are round holes or polygonal holes that are adapted, and the front limiting plate and the rear limiting plate are welded and fixed to the lower wing plate inside the holes through a welding process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com