Passivating agent regenerating and recycling equipment and method

A technology of passivating agent and equipment, applied in the direction of metal material coating process, etc., can solve the problems of non-renewable secondary use, high production cost, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

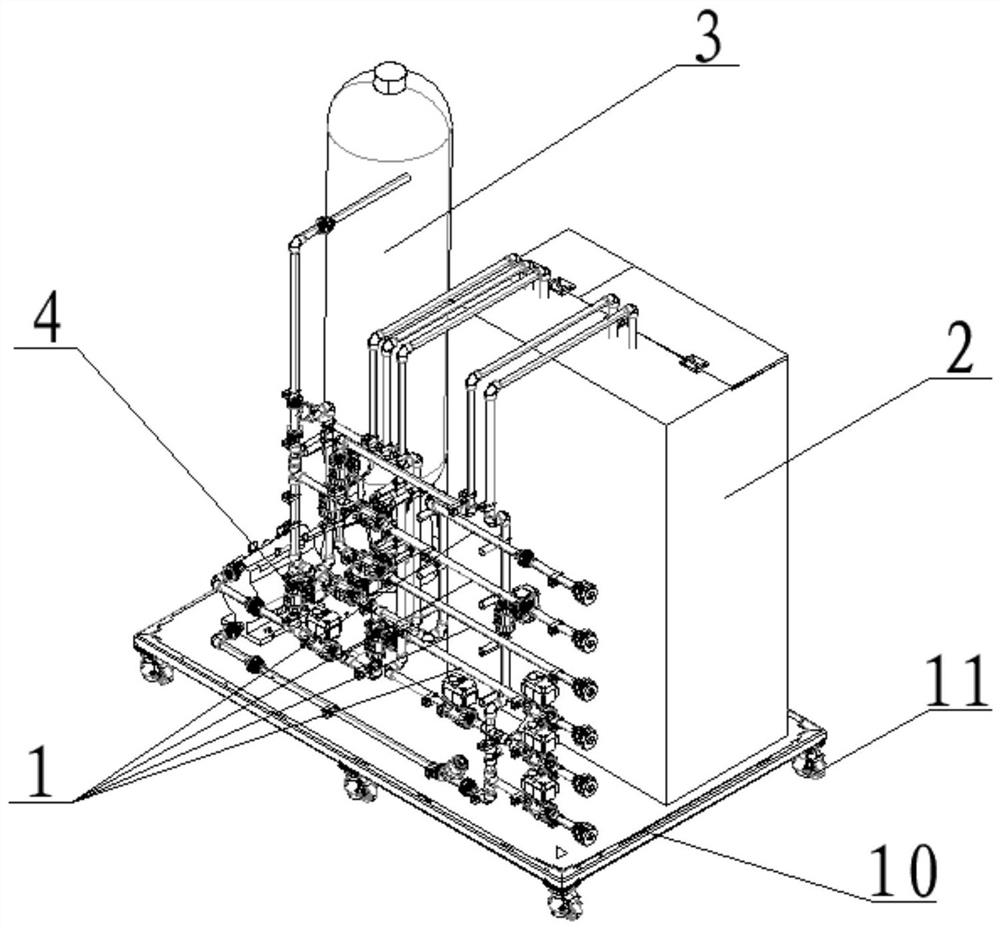

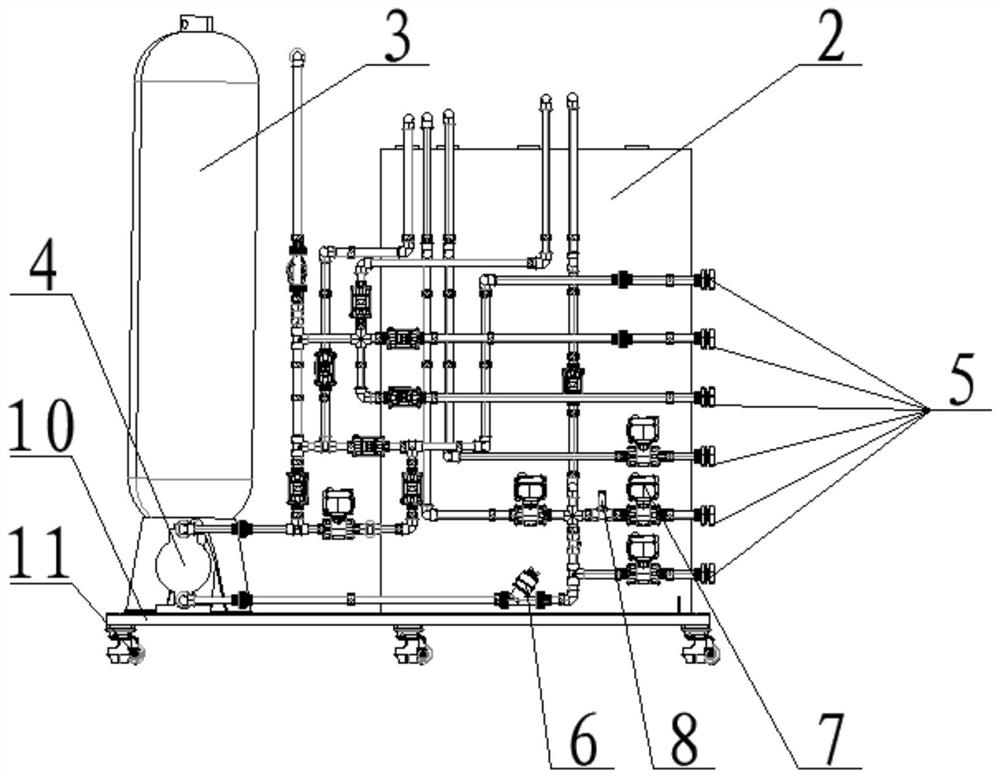

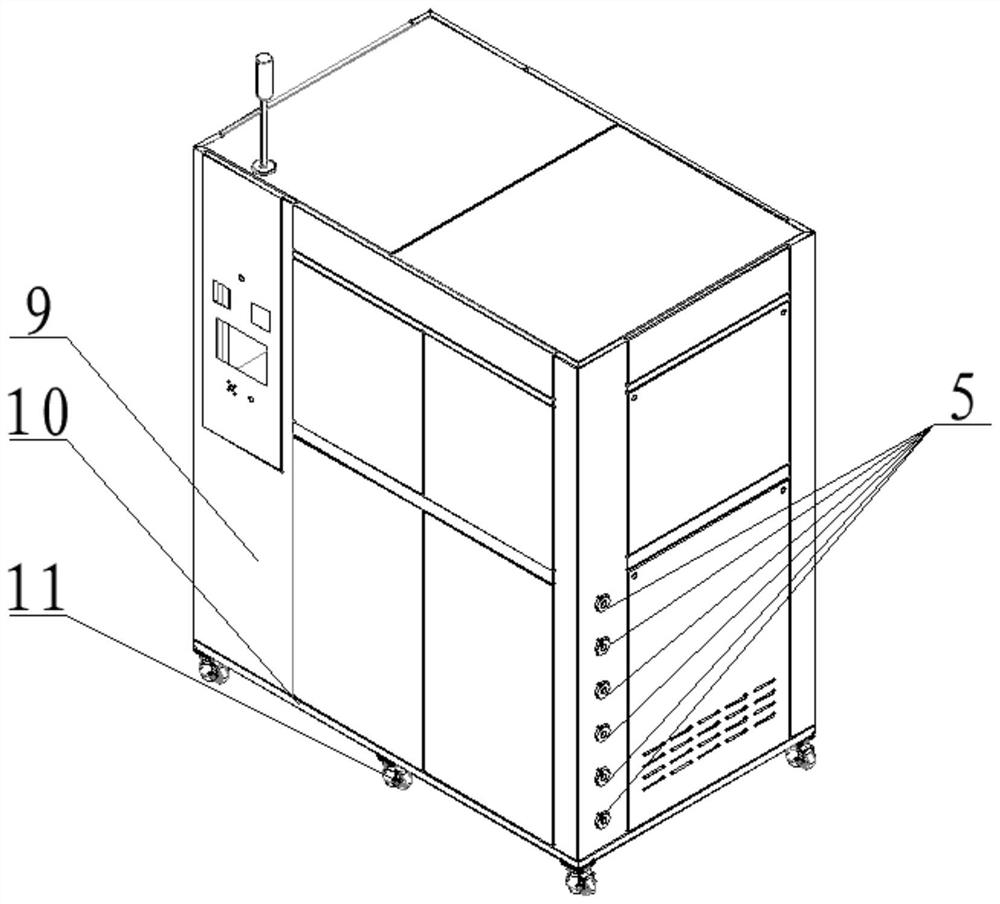

[0068] Figure 1~3 The passivator regeneration and reuse equipment shown includes a pipeline system 1, a water storage mechanism 2, a processing mechanism 3, and a power mechanism 4; the pipeline system 1 communicates with the water storage mechanism 2 and the processing mechanism 3, The power mechanism 4 is connected to the pipeline system 1; the pipeline system 1 is responsible for ensuring and controlling the circulation of gas and liquid; the water storage mechanism 2 is responsible for storage and retrieval of liquid; the processing mechanism 3 is responsible for The passivator is processed; the power mechanism 4 is responsible for providing electricity, water pressure and air pressure. Several ports 5 , filtering equipment 6 , valves 7 and sensors 8 are provided on the pipeline system. The port 5 from top to bottom is the passivating agent input port, the passivating agent output port, the cleaning liquid input port, the cleaning liquid output port, the regeneration liq...

Embodiment 2

[0070] Figure 1~3 The passivator regeneration and reuse equipment shown includes a pipeline system 1, a water storage mechanism 2, a processing mechanism 3, and a power mechanism 4; the pipeline system 1 communicates with the water storage mechanism 2 and the processing mechanism 3, The power mechanism 4 is connected to the pipeline system 1; the pipeline system 1 is responsible for ensuring and controlling the circulation of gas and liquid; the water storage mechanism 2 is responsible for storage and retrieval of liquid; the processing mechanism 3 is responsible for The passivator is processed; the power mechanism 4 is responsible for providing electricity, water pressure and air pressure. Several ports 5 , filtering equipment 6 , valves 7 and sensors 8 are provided on the pipeline system. The port 5 is, from top to bottom, the input port of the passivating agent, the input port of the regeneration solution, the input port of the cleaning solution, the output port of the pa...

Embodiment 3

[0072] Figure 1~3 The passivator regeneration and reuse equipment shown includes a pipeline system 1, a water storage mechanism 2, a processing mechanism 3, and a power mechanism 4; the pipeline system 1 communicates with the water storage mechanism 2 and the processing mechanism 3, The power mechanism 4 is connected to the pipeline system 1; the pipeline system 1 is responsible for ensuring and controlling the circulation of gas and liquid; the water storage mechanism 2 is responsible for storage and retrieval of liquid; the processing mechanism 3 is responsible for The passivator is processed; the power mechanism 4 is responsible for providing electricity, water pressure and air pressure. Several ports 5 , filtering equipment 6 , valves 7 and sensors 8 are provided on the pipeline system. The port 5 is, from top to bottom, the input port of the passivating agent, the input port of the regeneration solution, the input port of the cleaning solution, the output port of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com