Replacing and connecting structure of integral anti-collision wall with sideboard on elevated road and construction method of replacing and connecting structure

A technology for connecting structures and construction methods, applied in the erection/assembly of bridges, bridge parts, bridge maintenance, etc., can solve problems such as the impact on the quality of life of the surrounding people, limited operating space for large-scale machinery, and low construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

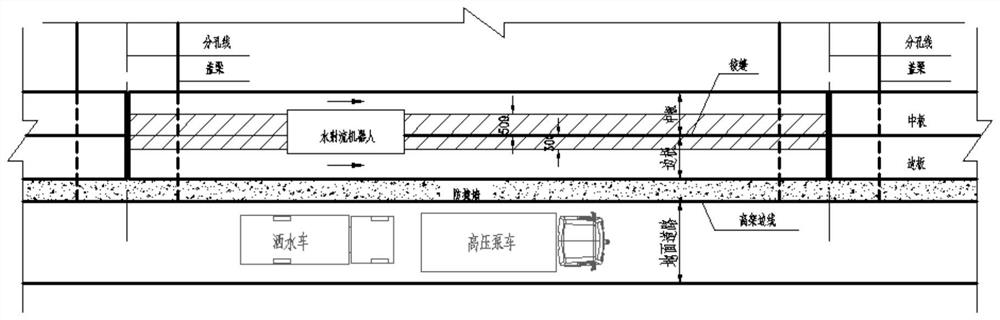

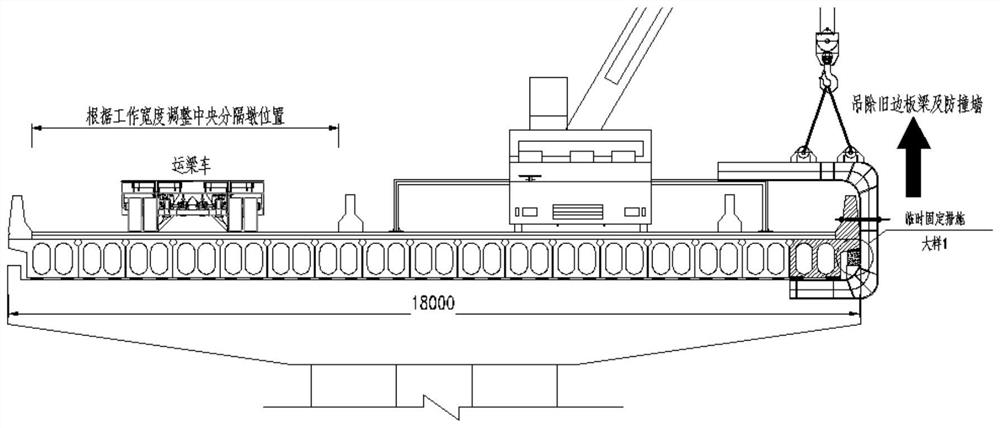

Method used

Image

Examples

Embodiment

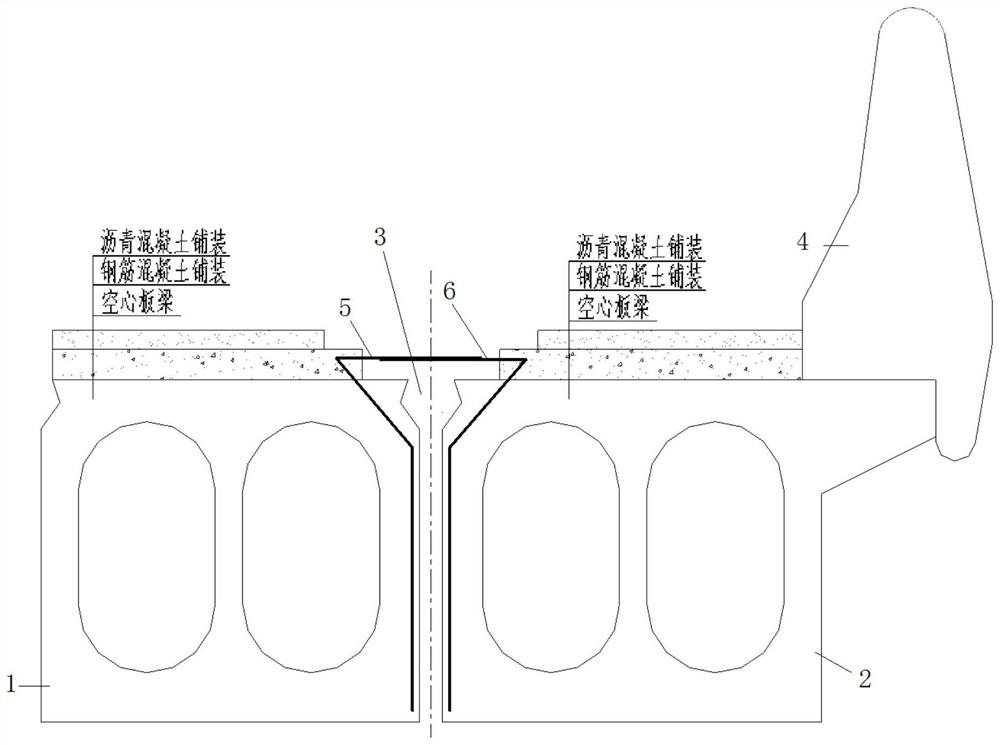

[0041] like figure 1 As shown in the figure, the replacement connection structure of the integrated anti-collision wall with side panels of the elevated road includes the old secondary side panel 1 and the new side panel 2; one side of the new side panel 2 is connected with the old secondary side panel 1 through the hinge 3, and the other side panel There are anti-collision walls 4 on the side;

[0042] The anti-collision wall 4 and the new side plate 2 are integral structures;

[0043] The old transverse connecting steel bar 5 of the old secondary side plate 1 and the new transverse connecting steel bar 6 of the new side plate 2 are connected above the hinge joint 3;

[0044] The hinged joint 3, and the old transverse connection steel bar 5 and the new transverse connection reinforcement bar 6 overlapped above the hinged joint 3 are consolidated into one body by filling with early-strength concrete.

[0045] In some embodiments, the structures of the old secondary side pane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com