Structural system of steel structure modular building

A steel structure, modular technology, applied in building structure, building, truss structure, etc., can solve the problems of difficult joint connection, space occupation, inapplicability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

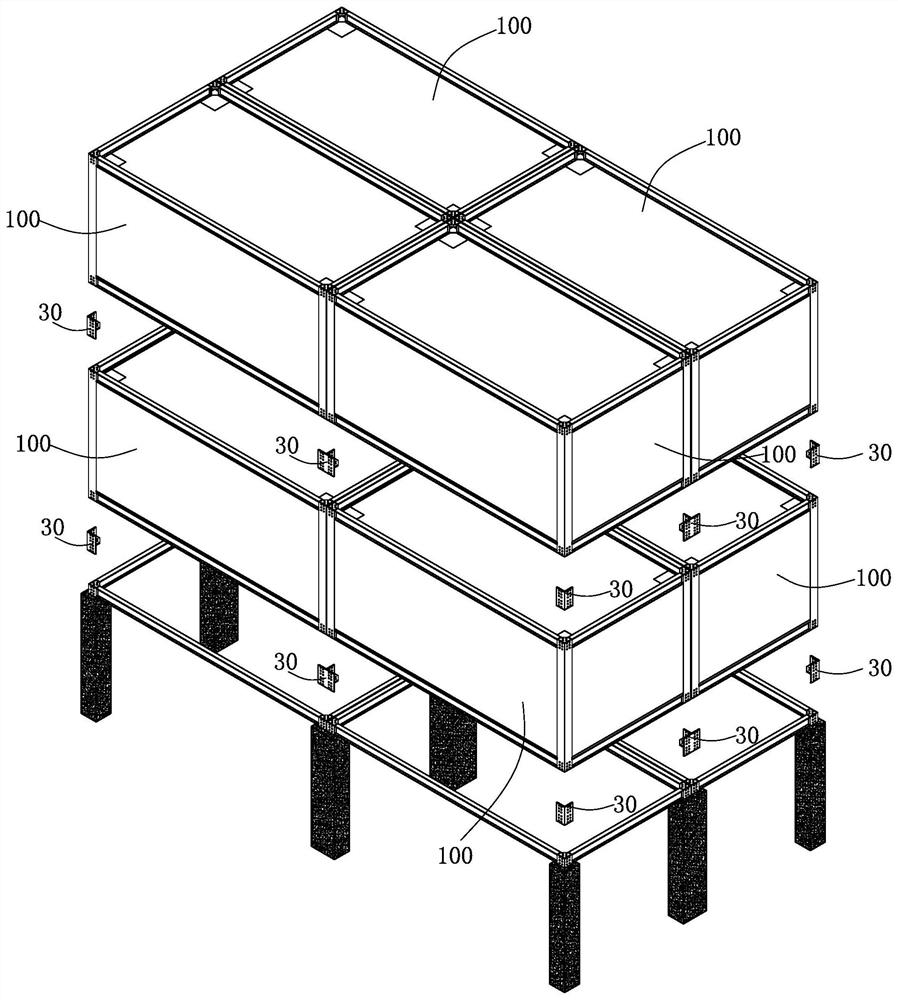

[0037] The present invention relates to a structural system of a steel structure modular building, which includes several unit modules 100 of the modular building. In this specific example, if Figure 1-20 As shown, eight steel structure unit frames 101 (standard unit module structure) are taken as an example for detailed description.

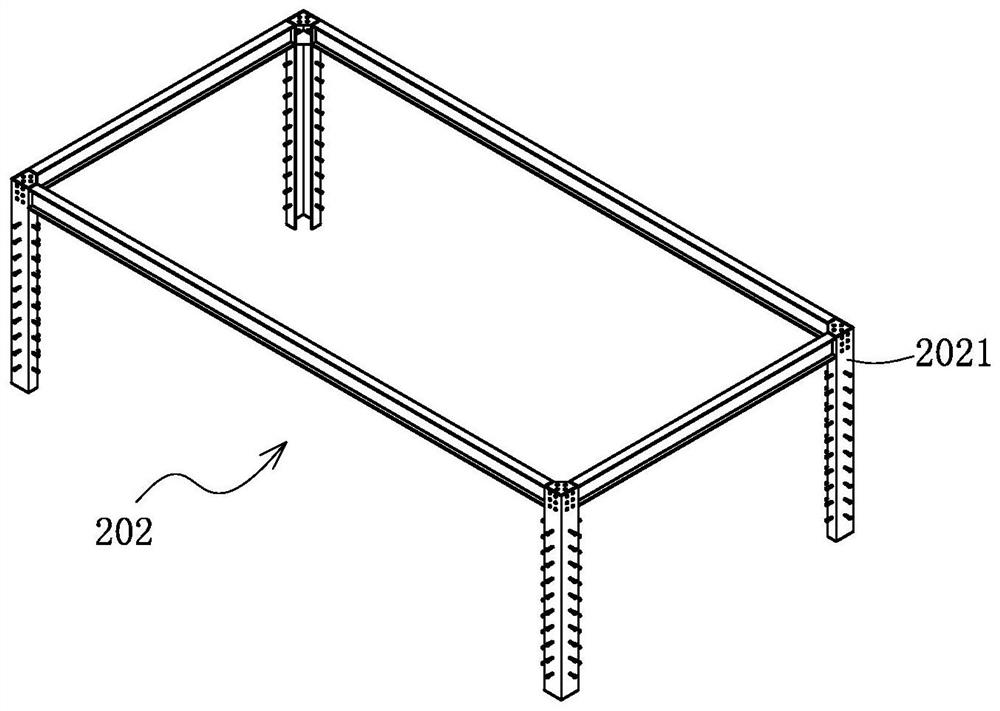

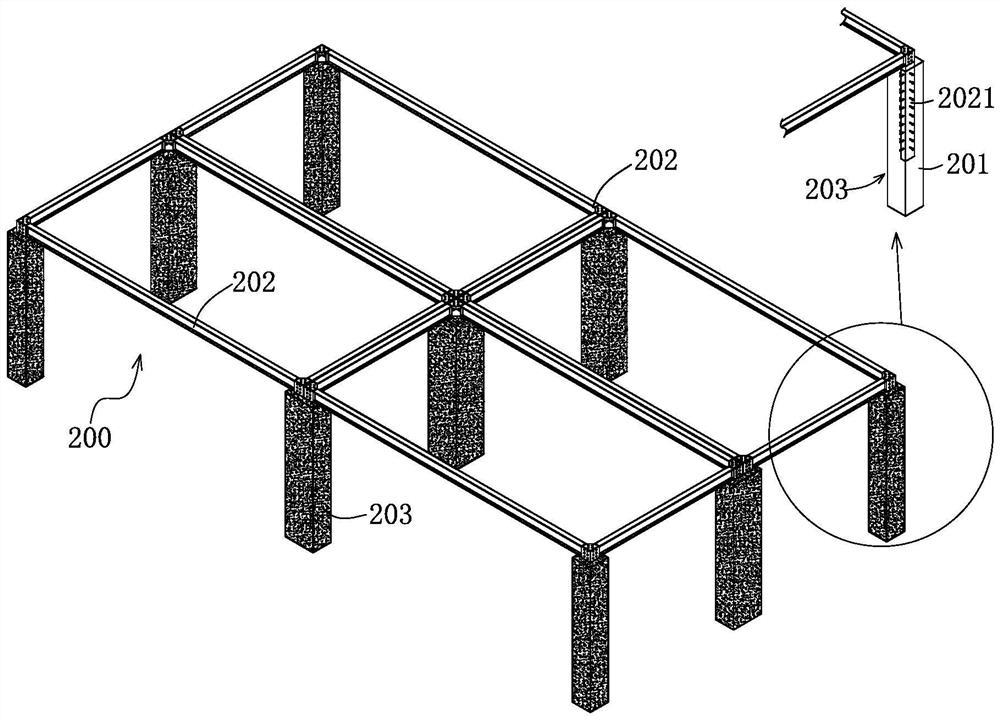

[0038] Such as Figure 1-3 As shown, eight unit modules 100 are divided into two layers and installed on the foundation structure 200 on the foundation. The basic structure 200 is the connection between the upper unit module 100 and the lower concrete structure 201. Taking the foundation as a concrete structure as an example, it includes the lower structure or the concrete structure 201 poured on the foundation and the steel structure chassis, the steel structure chassis It consists of four underframe modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com