Air leakage detection equipment for inflatable product

A technology of inflatable products and detection equipment, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree to measure the liquid tightness, etc., which can solve the problem of increasing the production cost of the manufacturer, the long detection time of the gas leakage detection equipment, and the detection Low efficiency and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

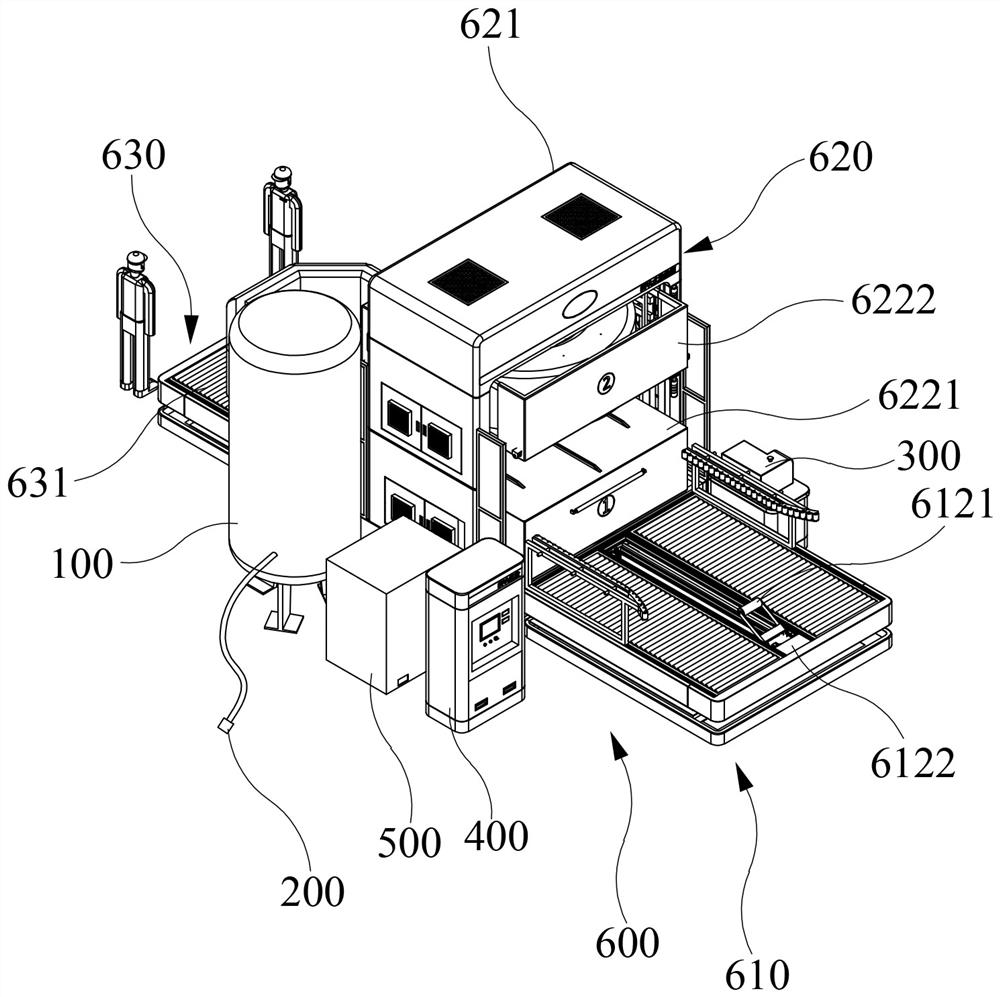

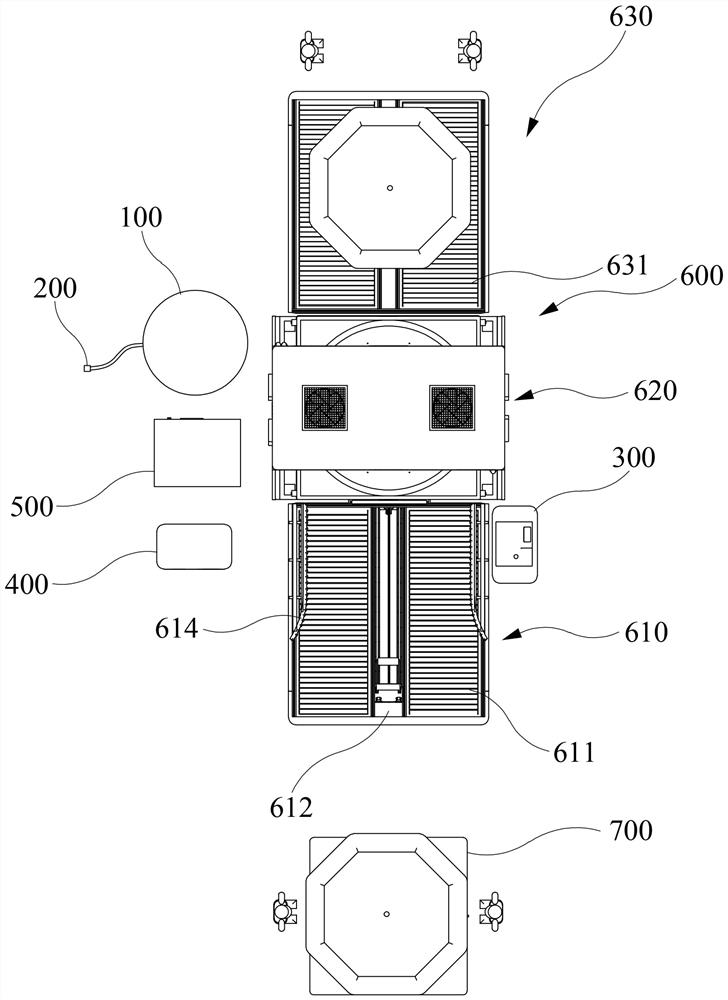

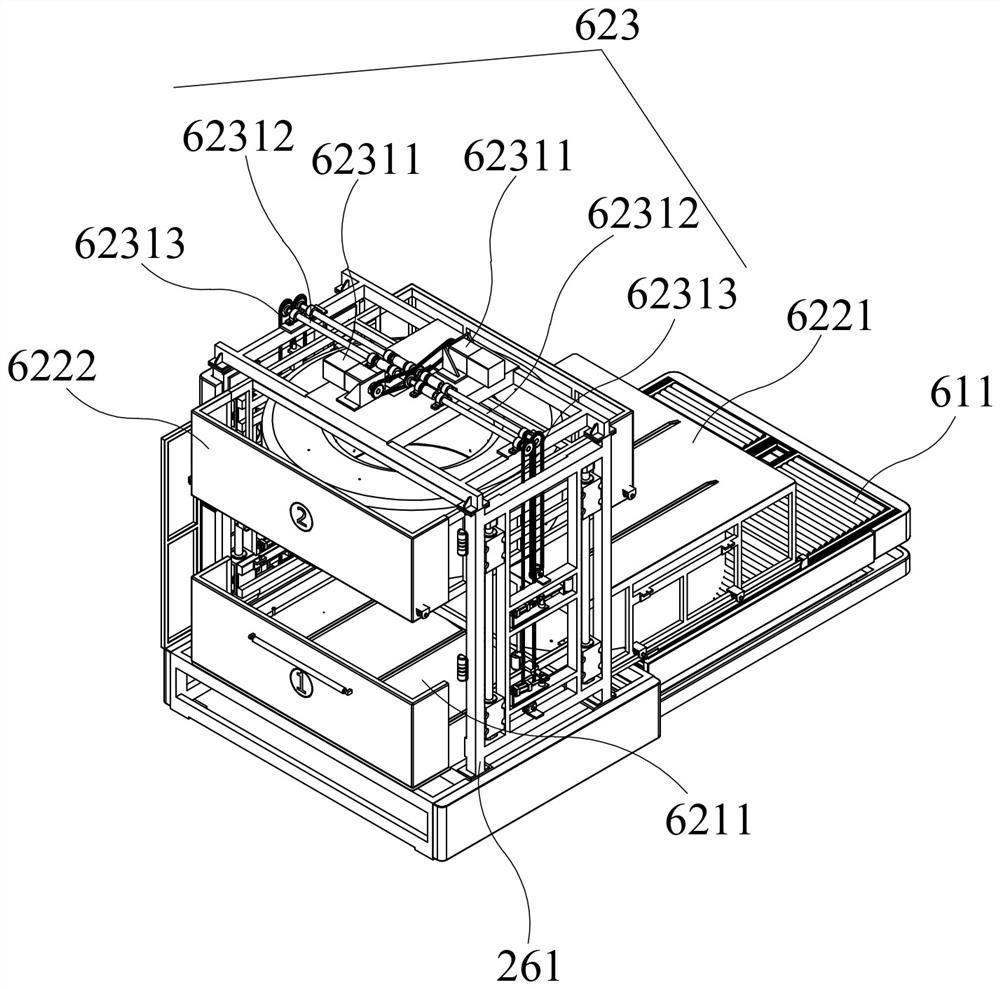

[0077] Such as Figure 1-4 As shown, the air leakage detection equipment of this embodiment is provided with a test line 600 , and the test line 600 is equipped with an air storage tank 100 , an inflator 200 , a tester 300 and an electric control box 400 . Wherein, the gas storage tank 100 is used for storing gas. The inflator 200 is connected to the gas tank 100, through which the gas in the gas tank 100 can be charged into the inflatable product 700; the inflator 200 can also be connected to the electric control box 400, and the electric control box 400 controls the inflator 200 for inflation operation. In this embodiment, the inflation device 200 is an inflation head. The tester 300 is connected to the electric control box 400, and the control box of the electric control box 400 detects whether the inflatable product 700 on the test line 600 is leaking. In this embodiment, the tester 300 can use a pressure tester 300, a gas mass spectrometer or other types of tester 300....

Embodiment 2

[0093] The concept of the second embodiment is the same as that of the first embodiment, the difference is that the air leakage detection equipment of the second embodiment includes two test lines 600, that is, the two test lines 600 are equipped with an air storage tank 100, an inflator 200, A tester 300, an electric control box 400. In addition, in this embodiment, each test line 600 includes a loading station 610, a testing station 620, and an unloading station 630, wherein the testing station 620 can be provided with one or more than two testing covers. When the test station 620 is provided with more than two test covers, the loading station 610, test station 620 and unloading station 630 of each test line 600 have the same structure as that of Embodiment 1. When the test station 620 is provided with a test cover, the loading station 610 and the unloading station 630 do not have the loading and unloading device 613 and the unloading lifting device 632, and the other parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com