Method for determining vertical rigidity of large-opening structure of rectangular fuselage cabin

A large opening, fuselage technology, applied in the field of determining the vertical stiffness of the large opening structure of the rectangular fuselage cabin, can solve the problems of lack of design technology and experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

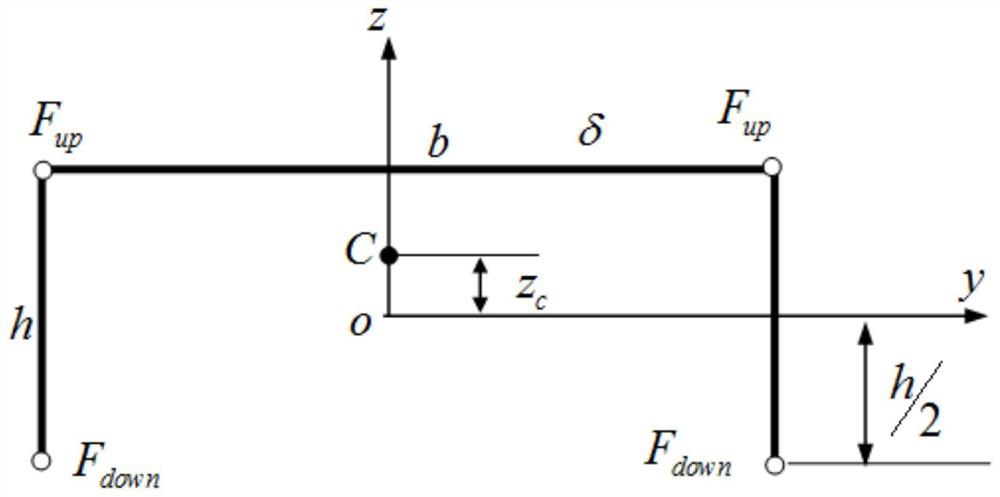

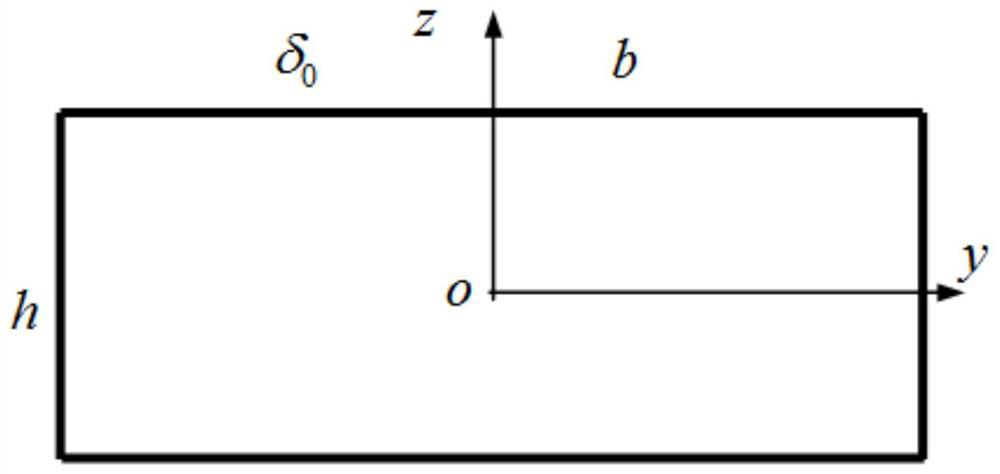

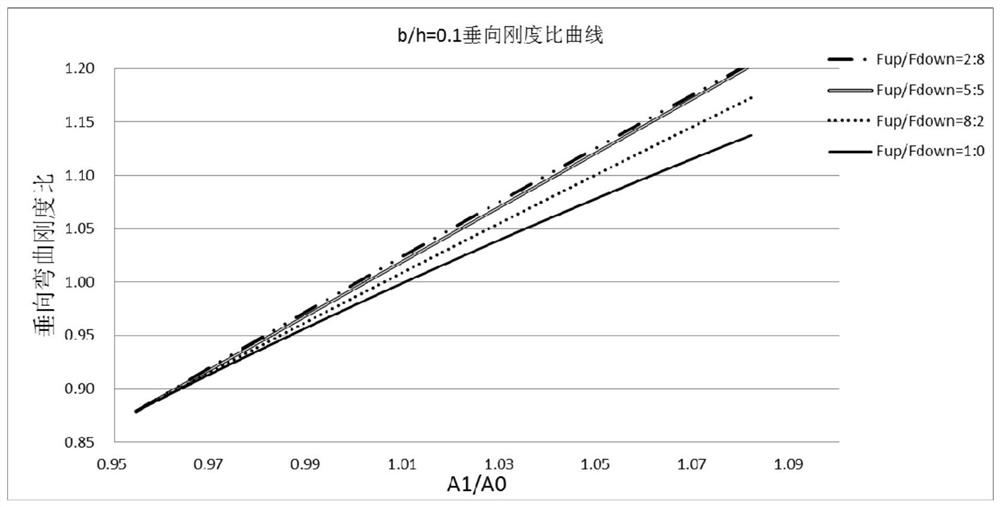

[0115] For a rectangular fuselage section, its width is b=3000mm, its height is h=1500mm, and its wall thickness is δ 0 = 2mm, due to the large opening of the cabin, the lower wall needs to be strengthened by arranging side beams at four corners. When the vertical bending stiffness is consistent with the rigidity of the model without openings, the area F of the side beams to be compensated up with F down How to determine?

[0116] method one:

[0117] 1) From the structure size data,

[0118] When the vertical bending stiffness of the strengthened model is required to be consistent with that of the model before the opening, ξ=1;

[0119] Ruocha F up / F down =2:8 curve, p=1.02 can be obtained.

[0120] Then the areas of the upper and lower side beams are respectively:

[0121]

[0122] Ruocha F up / F down =5:5 curve, available: p=1.10

[0123] Then the areas of the upper and lower side beams are respectively:

[0124]

[0125] Method Two:

[0126] When the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com