Imaging system and detection method for defects in mobile phone metal middle frame

A metal middle frame and imaging system technology, which is used in optical testing of flaws/defects, measuring devices, and material analysis by optical means, can solve problems such as difficult imaging, optimize shooting angles, improve detection efficiency, and improve imaging. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

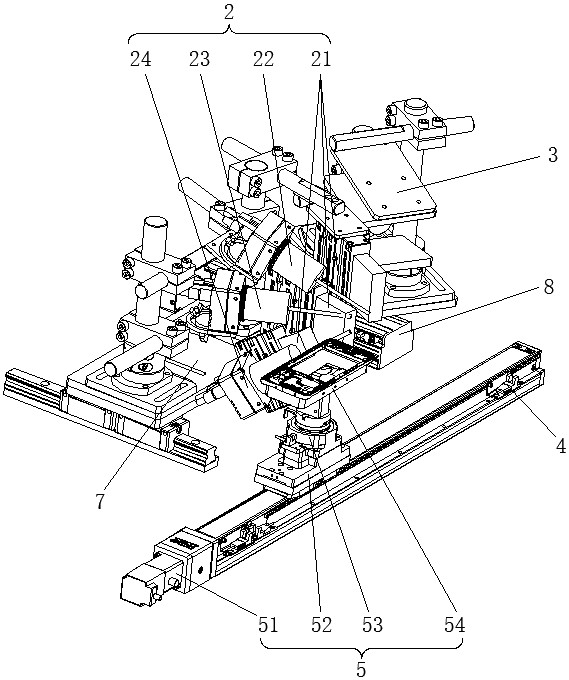

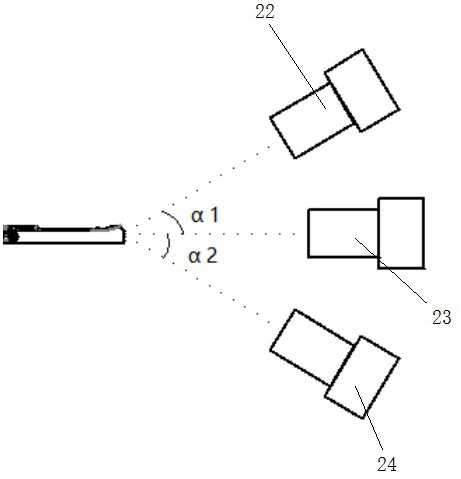

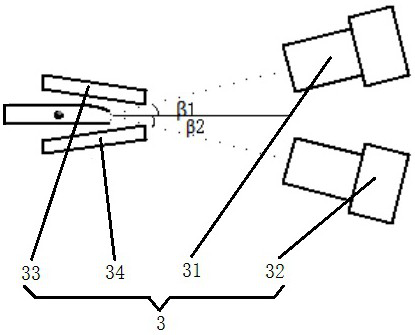

[0073] See Figure 1 to Figure 5 In the present invention, the mobile phone metal middle frame defect imaging system includes a line array camera module 2 electrically connected to the control unit 1 and controlled by the control unit 1, an area array camera module 3, a position sensing module 4 and a device for carrying the product to be inspected and driving The carrying module 5 of the linear motion of the product to be inspected; the line array camera module 2 is used to scan the side of the product to be inspected that moves linearly with the carrying module 5, and the area array camera module 3 is used to scan the side of the product to be inspected The corner of inspection product is taken picture; Described line array camera module 2 comprises three line array cameras that lens is housed and three line light sources 21; One line light source 21 cooperates with a line array camera to take pictures; Three line array cameras The cameras are respectively an upper side line...

Embodiment 2)

[0117] In the mobile phone metal middle frame defect imaging system of the present invention, neither the carriage 7 nor the second linear drive device 8 is provided, nor is the rotary drive device 53 provided. Other technical characteristics are identical with embodiment 1.

[0118] The present invention uses the above-mentioned mobile phone metal middle frame defect imaging system to carry out the detection method, comprising the following steps:

[0119] S1. Loading: place the product to be inspected on the carrier module 5;

[0120] S2. Side view: the carrier module 5 carries the product to be inspected in a straight line. When the position sensing module 4 senses that the product to be inspected on the carrier platform 54 enters the starting end of the line scan, the upper side of the line array camera module 2 will The array camera 22, the middle side line array camera 23 and the lower side line array camera 24 simultaneously scan a side of the passing product to be ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com