Production-type two-dimensional liquid chromatography interface and production-type two-dimensional liquid chromatography separation system

A two-dimensional liquid chromatography and separation system technology, which is applied in the field of production-type two-dimensional liquid chromatography interface and production-type two-dimensional liquid chromatography separation system, can solve the problems of small injection volume and two-dimensional separation synchronization that have not been thoroughly solved Solve and fail to complete large-scale sample preparation and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

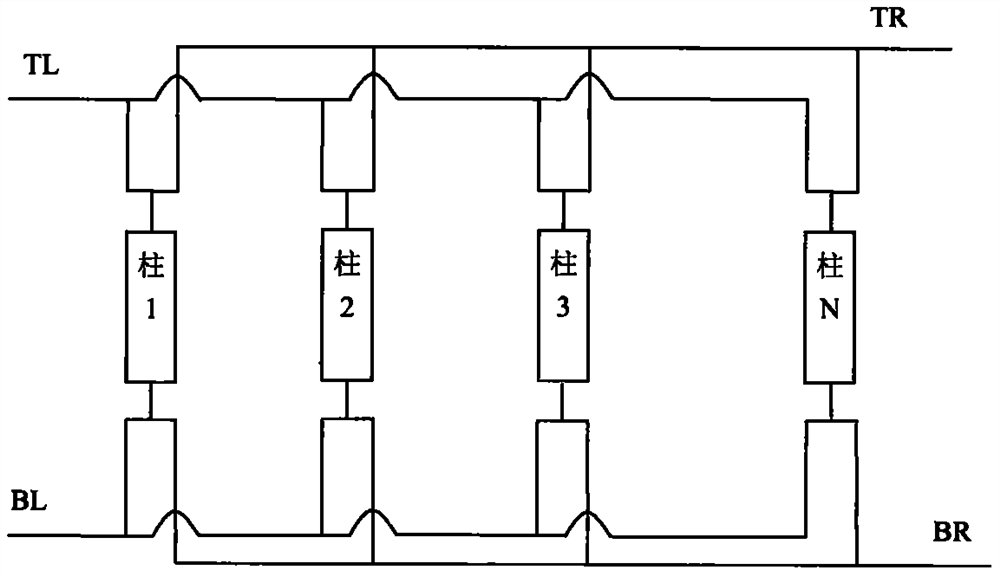

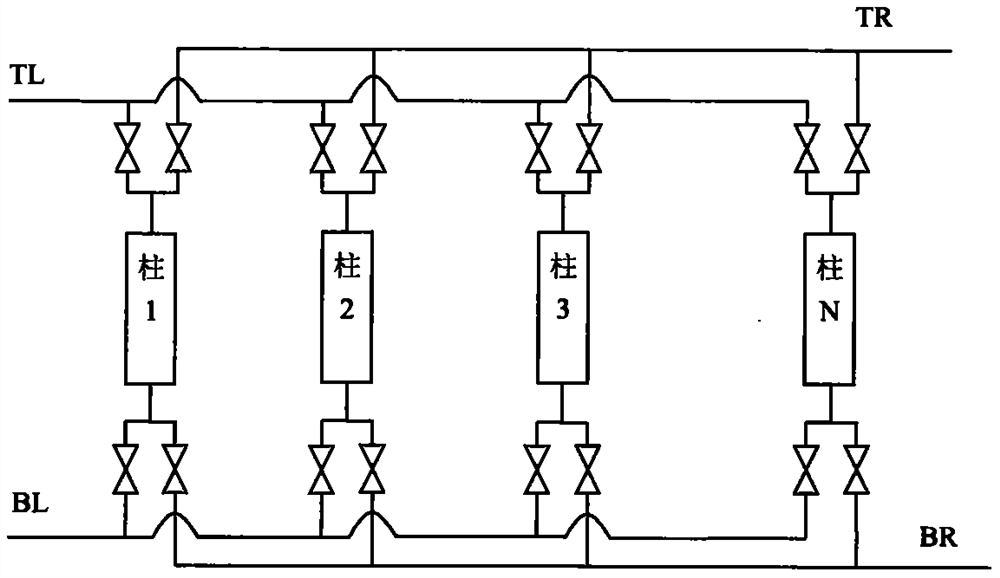

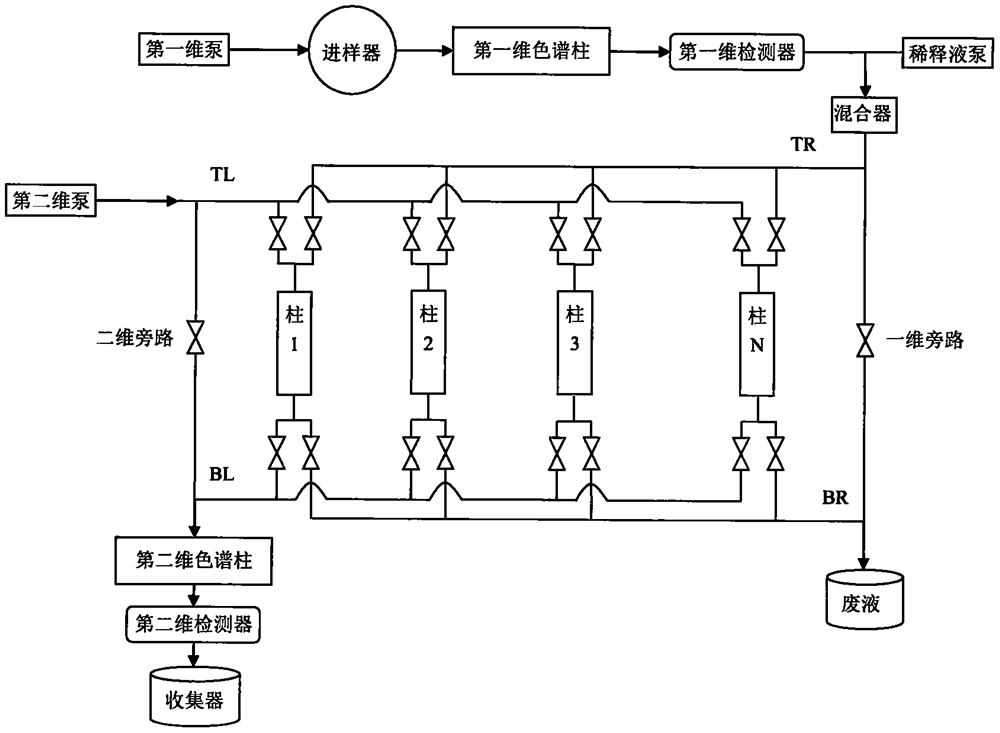

[0037] Example: A production-type two-dimensional liquid chromatography separation system structure

[0038] In this embodiment, the sampling method is first-dimensional pump injection, and the number of enrichment columns in the enrichment column array is 4, which are sequentially numbered as the first enrichment column, the second enrichment column, and the second enrichment column of the enrichment column array. 3 enrichment column, the 4th enrichment column; Figure 4 (a) is the first dimension loading state of the production type two-dimensional liquid chromatography separation system, and Figure 4 (b) is the state of the production type two-dimensional liquid chromatography separation system The first dimension and the second dimension work in parallel.

[0039] The following is the two-dimensional separation process control of the above-mentioned production-type two-dimensional liquid chromatography separation system structure:

[0040] First clean the enrichment column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com