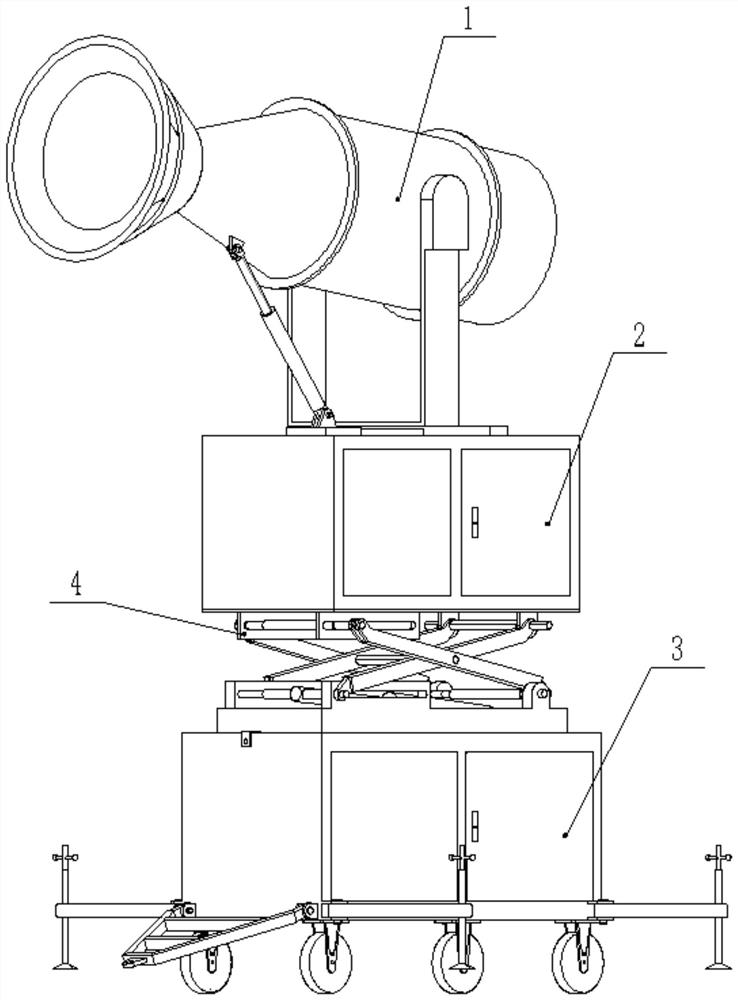

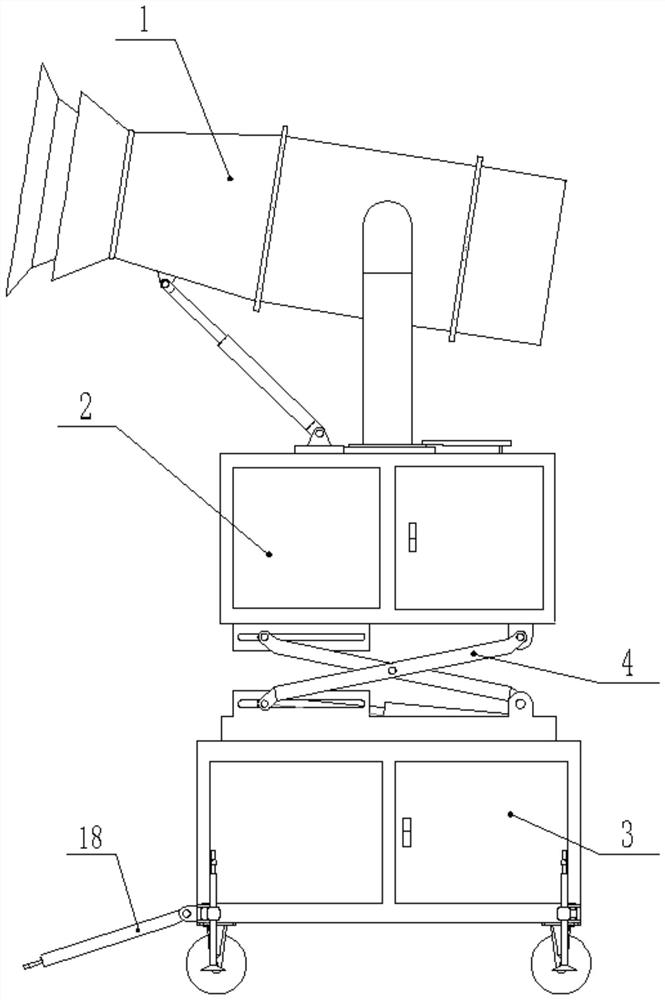

Spraying and dust settling device for building construction

A technology for spray dust reduction and building construction, which is applied in the field of sprayers and can solve the problems of water waste, small angle of water mist, and long range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

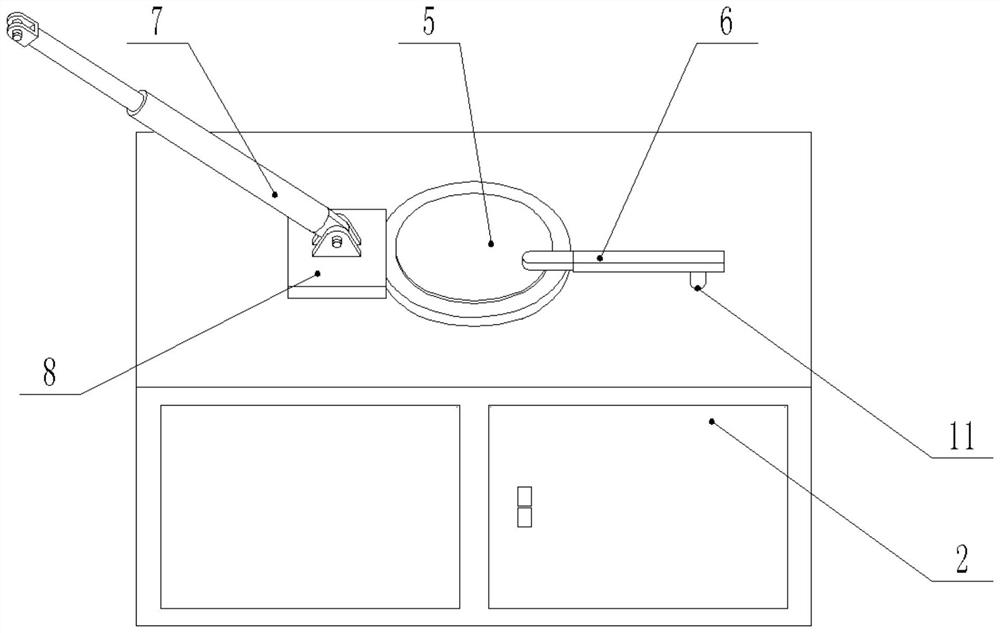

Method used

Image

Examples

specific Embodiment approach

[0031] Specific embodiments of the present invention: when the spray dust suppression device for building construction is in the working process, the fixed frame 22 is opened first, the control adjustment handle 23 is made to lower the support rod 24, the support disc 25 is in contact with the ground and fixed, and then the Dust suppression by spraying. The movement of the first folding rod 12 and the second folding rod 13 is realized by pushing and pulling the first synchronous rod 14 through the third cylinder 15 , thereby realizing lifting control. When the output end of the first air cylinder 6 is stretched, it is extruded by an external force, and the output end of the first air cylinder 6 pushes the rotating disc 5 to rotate to realize the steering function. In this way, spray dust reduction operations at different heights and directions can be realized. When the sprayer main body 101 was carrying out the spraying operation, a part of the sprayed mist was sprayed out by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com