Spraying line VOCs waste gas treatment device

A technology of waste gas treatment device and spraying line, which is applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of slow drying speed, long treatment time, complicated organic waste gas treatment process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

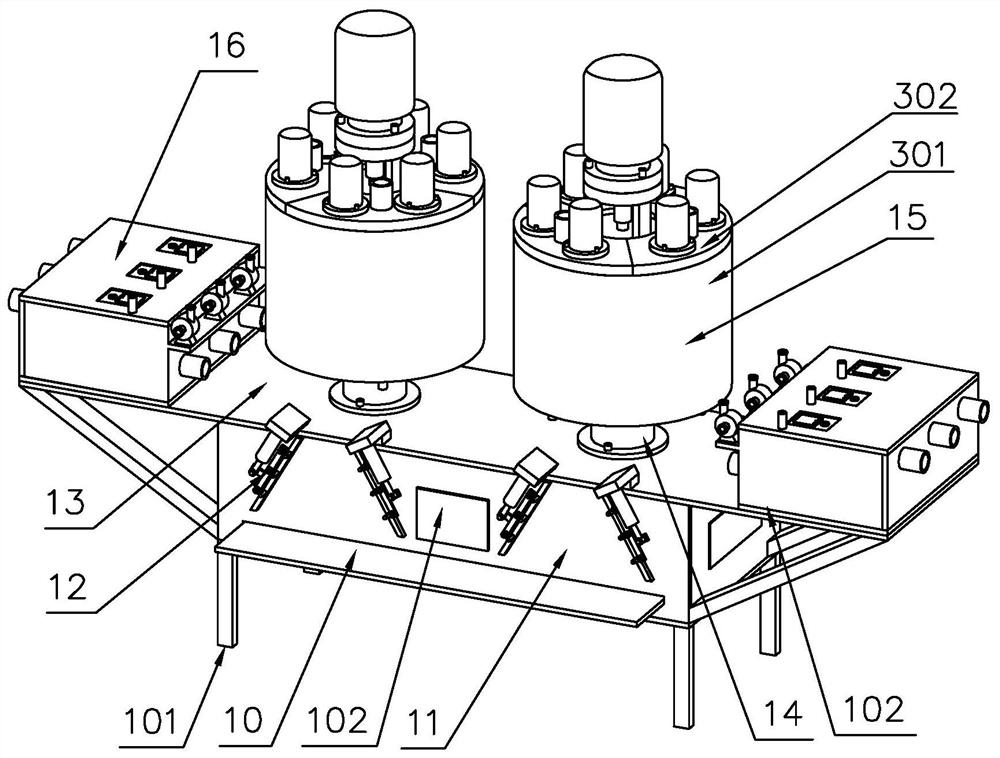

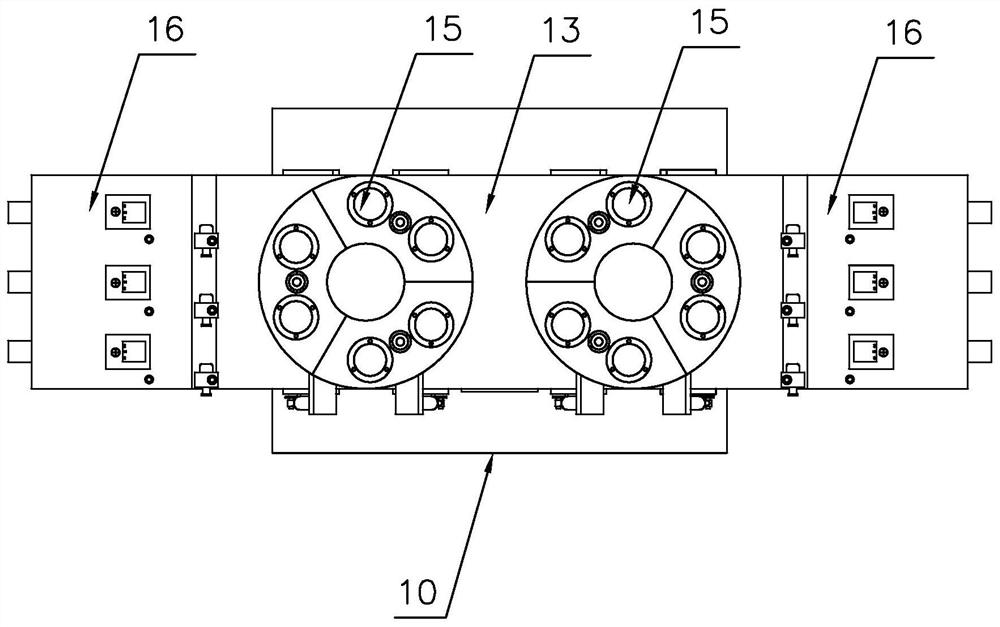

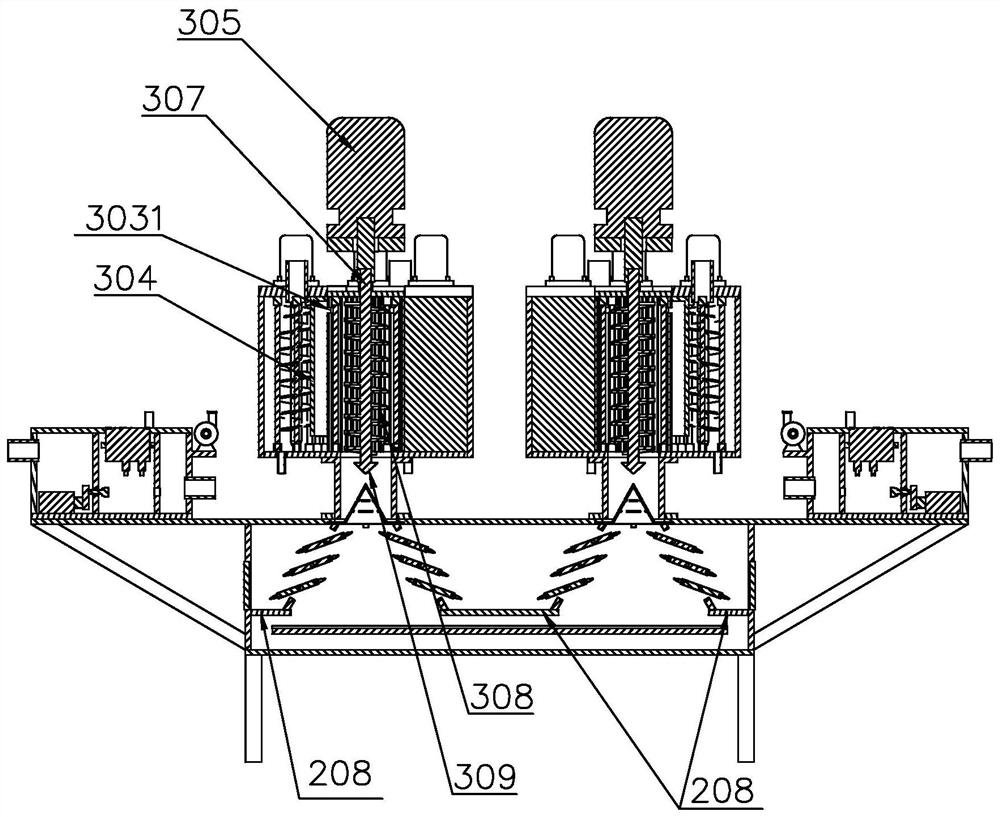

[0026] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-7 , to further specifically describe the technical solution of the present invention.

[0027] A VOCs exhaust gas treatment device for a spraying line, comprising a spraying box 11, a flow guide mechanism 12, a support platform 13, a circular support pipe 14, a catalytic decomposition mechanism 15, and a flow guide hood 17; the bottom of the spraying box 11 is provided with Support leg 101, spraying box body 11 inside is provided with diversion mechanism 12; Spraying box body 11 top is provided with support platform 13; A shroud 17 is provided between the supporting pipes 14; a catalytic decomposition mechanism 15 is provided on the upper part of the circular supporting pipe 14, and the catalytic decomposition mechanism 15 is connected to the centrifugal fan through a pipeline.

[0028] The guide mechanism 12 includes a support frame 201, a rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com