Garbage can opening coloring all-in-one machine

An all-in-one machine and trash can technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of unrecyclable, cumbersome operation process, waste of dyes, etc., and achieve good coloring effect, simple operation, and low cost. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

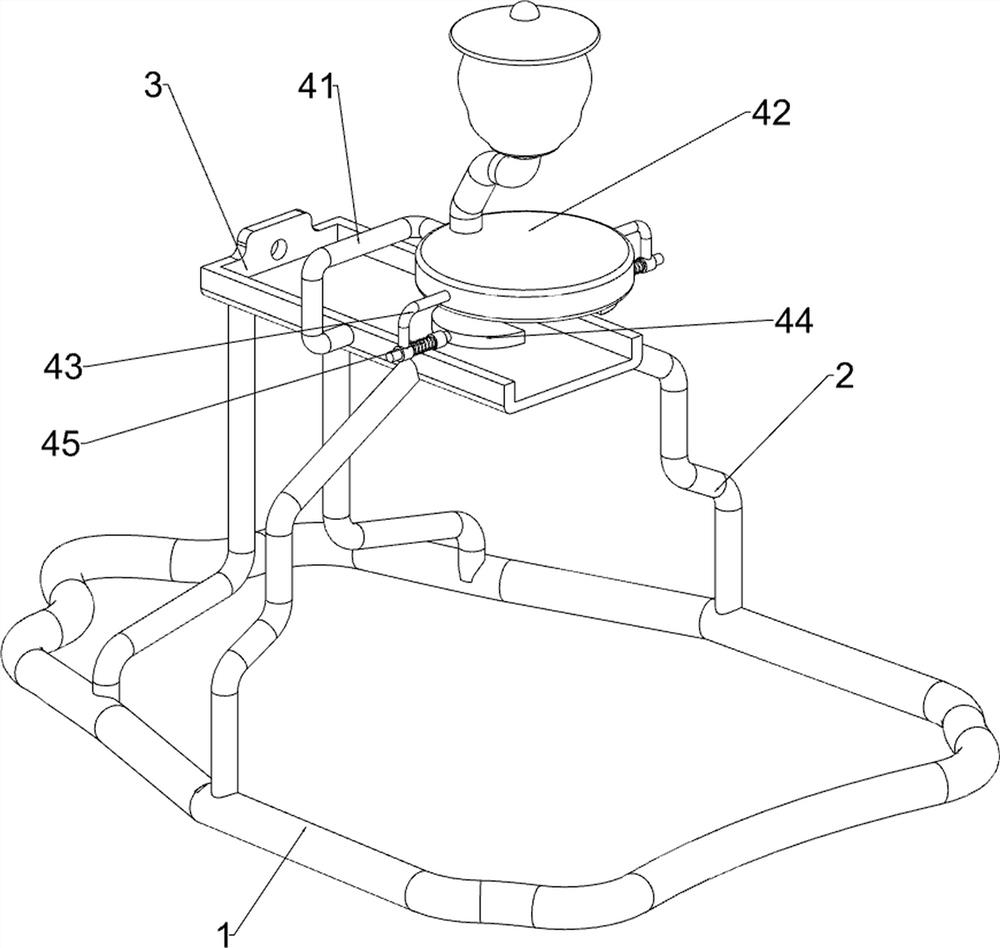

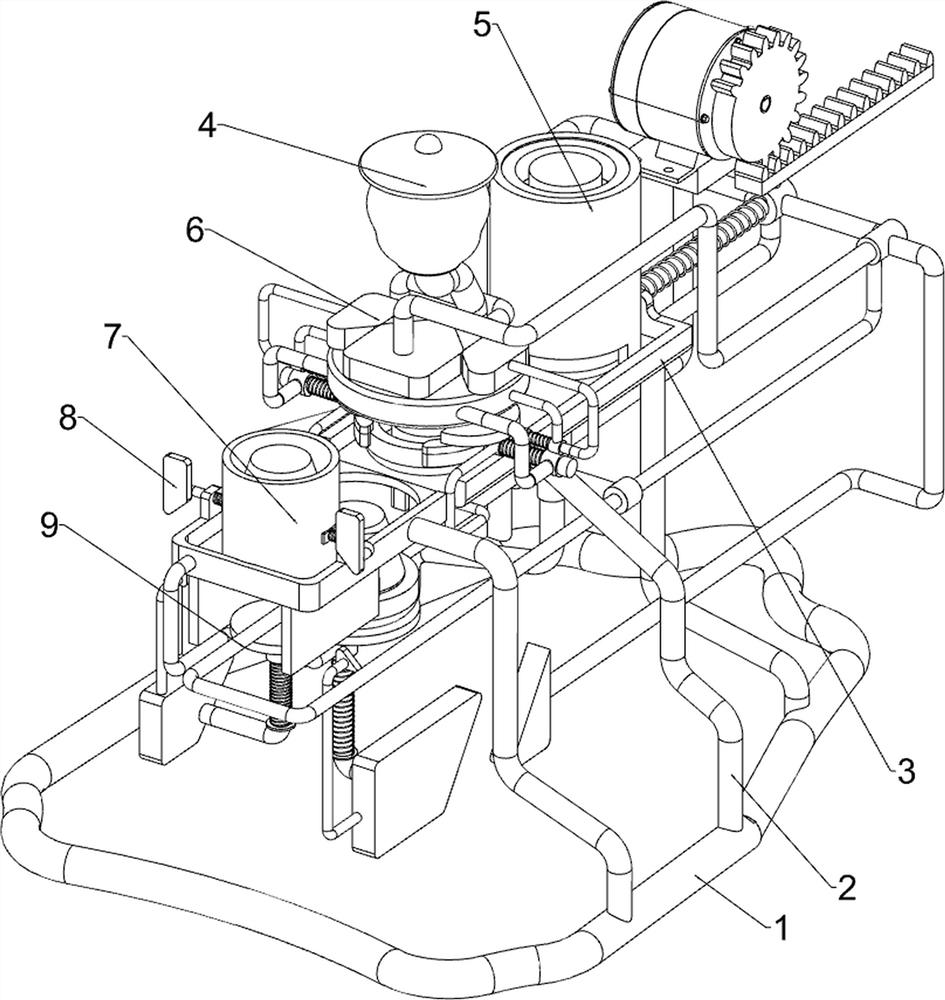

[0030] An all-in-one machine for coloring the mouth of a trash can, such as Figure 1 to Figure 3 As shown, it includes a base 1, a support rod 2, a workbench 3, a launching mechanism 4, and a plate-releasing mechanism 5. A support rod 2 is connected in the middle of the top of the base 1, and a workbench 3 is connected to the top of the support rod 2, and the workbench 3 is installed A launching mechanism 4 is arranged, and a plate-setting mechanism 5 is connected between the workbench 3 and the base 1 .

[0031] The launching mechanism 4 includes a first fixed rod 41, a storage tank 42, a first sliding sleeve 43, a sliding water blocking plate 44 and a first spring 45. The middle part of the workbench 3 is connected with a first fixed rod 41, and the first fixed rod 41 The top of the storage tank 42 is connected with the storage tank 42, the left and right side walls of the storage tank 42 are connected with the first sliding sleeve 43, the first sliding sleeve 43 is connect...

Embodiment 2

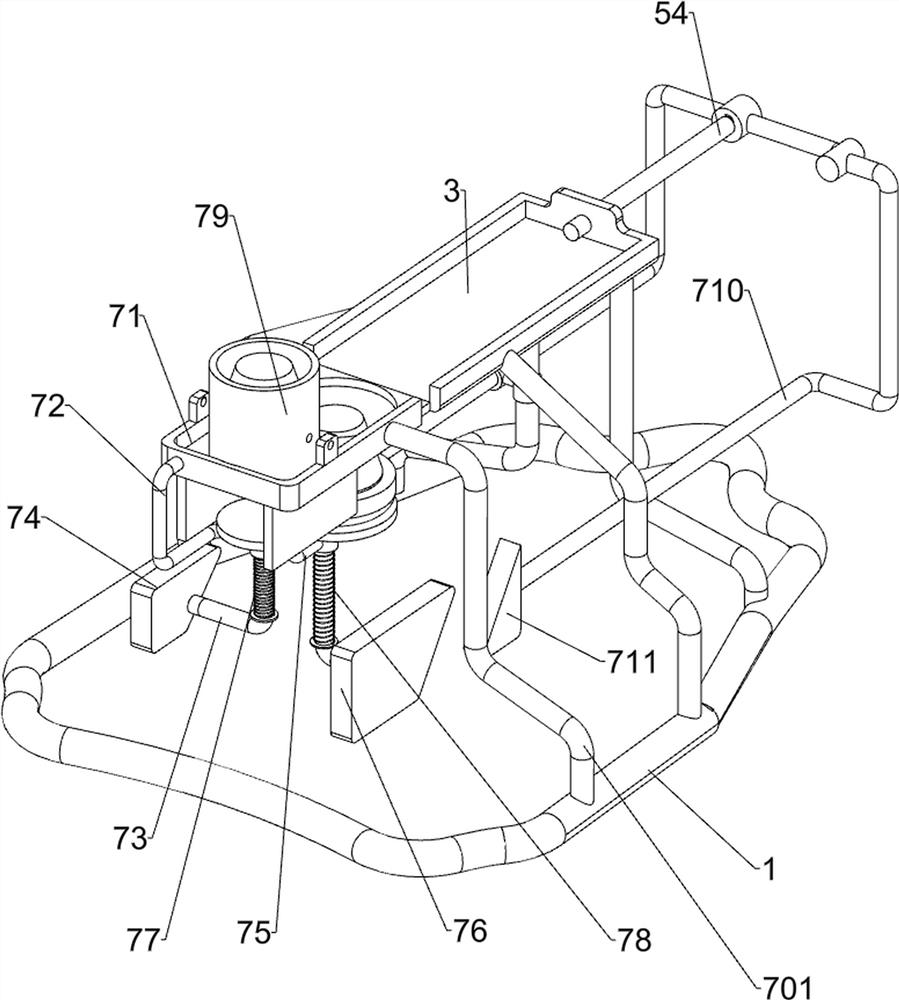

[0035] On the basis of Example 1, such as Figure 4 with Figure 5As shown, it also includes an automatic intermittent launching clamping mechanism 6, and the automatic intermittent launching clamping mechanism 6 includes a first connecting rod 61, a trapezoidal plate 62, a first inclined block 63, a second sliding sleeve 64, a first clamping Plate 65, the third spring 66, the second oblique block 67 and trapezoidal block 68, the rear right side of the push rod 54 is connected with the first connecting rod 61, the tail end of the first connecting rod 61 is connected with the trapezoidal plate 62, The tail end of the sliding water blocking plate 44 is connected with a first inclined block 63, the trapezoidal plate 62 is located between the first inclined blocks 63 on the left and right sides, the first inclined block 63 is in contact with the trapezoidal plate 62, and the storage tank The left and right sides of 42 are all connected with the second sliding sleeve 64, and the s...

Embodiment 3

[0040] On the basis of Example 2, such as Figure 8 As shown, an auxiliary intermittent blanking mechanism 8 is also included, and the auxiliary intermittent blanking mechanism 8 includes a fifth inclined block 81, a second clamping plate 82 and a sixth spring 83, the third inclined block 74 and the fourth inclined block. The block 76 is connected with a fifth oblique block 81, the left and right sides of the top of the connecting plate 71 are slidably connected with a second clamping plate 82, and the second clamping plate 82 and the connecting plate 71 are connected with a second clamping plate 82 Six springs 83, the outer end of the second clamping plate 82 is also connected with the fifth inclined block 81.

[0041] Garbage bins are stacked in the material bucket 79, when the third oblique block 74 and the fourth oblique block 76 moved upwards, the fifth oblique block 81 on it moved up thereupon, and the third oblique block 74 When the fourth inclined block 76 moves upwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com