Clamping mechanism for collet chuck of CNC lathe

A spring chuck and clamping mechanism technology, applied in the direction of the chuck, etc., can solve the problems of tool scrap, tool jitter, workpiece scrap, etc., and achieve the effect of reducing jitter, uniform force and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

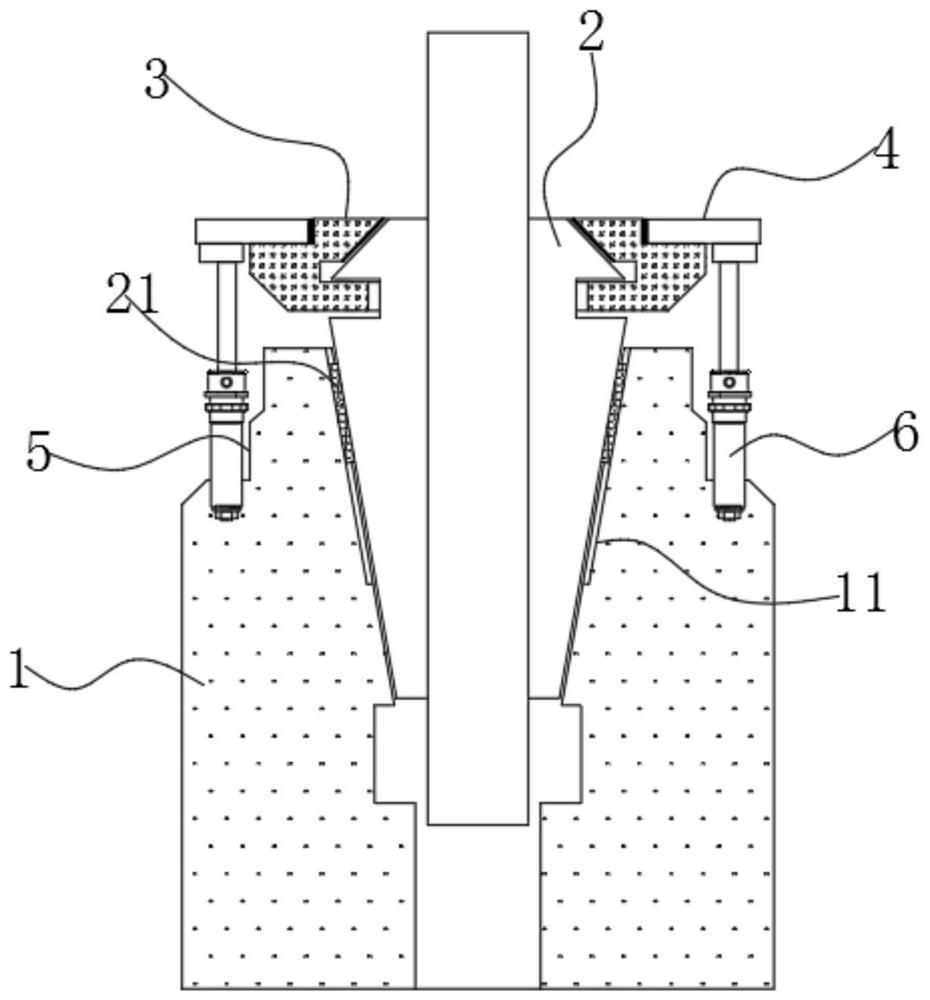

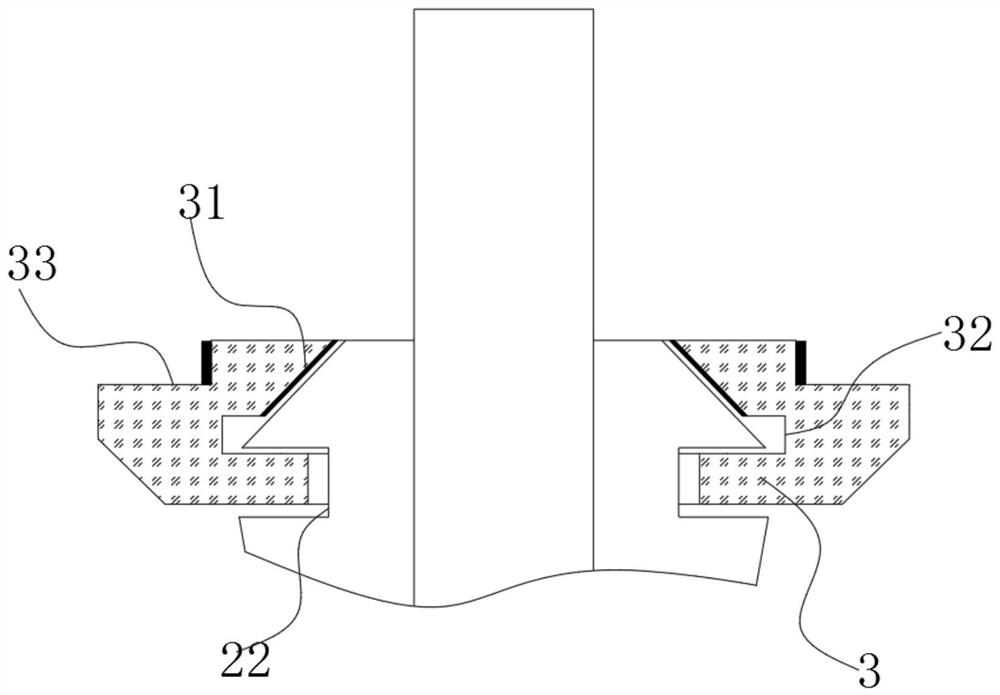

[0026] Specific implementation mode one: see Figure 1-4 This embodiment will be described. The clamping mechanism of the collet collet of the CNC lathe described in this embodiment includes a tool handle 1, a clamping sleeve 3 and a telescopic rod 6, wherein a through slot is opened in the middle of the tool handle 1 for passing a tool, and the There is also a tapered locking groove at the through groove at one end of the handle for locking the collet 2;

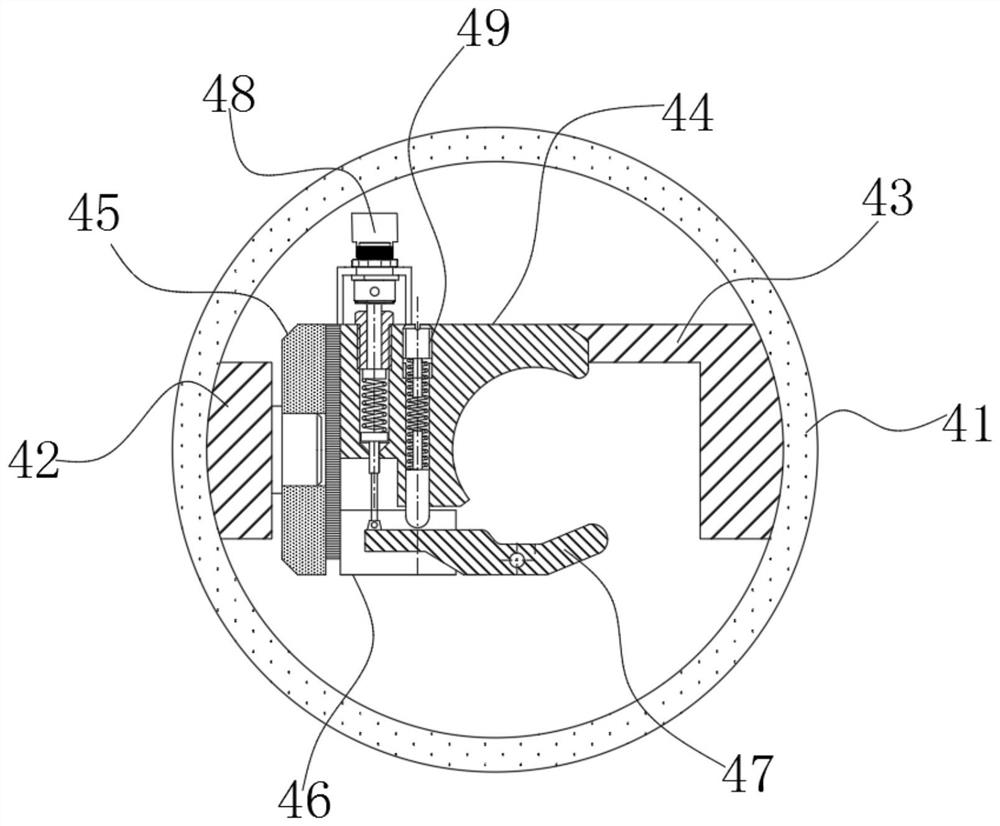

[0027] The outer sleeve of the collet 2 is provided with a clamping sleeve 3, and the clamping sleeve 3 is connected with a plurality of sets of telescopic rods 6 by a clamping assembly 4, and the other end of the telescopic rod 6 is fixedly embedded in the handle 1 ;

[0028] The clamping force exerted by the clamping assembly 4 on the clamping sleeve 3 can be absorbed by the clamping sleeve 3, preventing the clamping assembly 4 from applying a clamping force to the collet 2 through the clamping sleeve 3, so that The sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com