Metal pipe equal-distance cutting equipment for high-end equipment

An isometric cutting, metal tube technology, applied in metal processing equipment, shearing equipment, shearing devices, etc., can solve the problems of inconsistency, long time consumption, low cutting efficiency, etc., to prevent displacement, precise cutting, and reduce noise. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

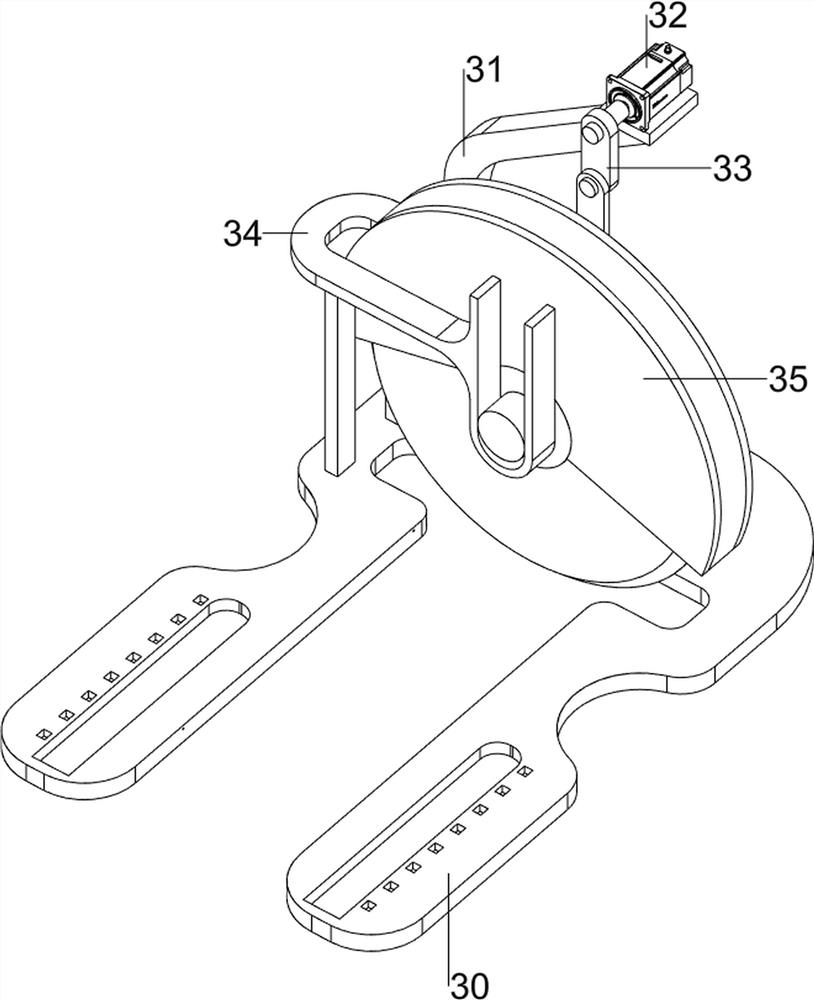

[0025] A metal pipe isometric cutting equipment for high-end equipment such as figure 1 As shown, base plate 1, support 2, cutting mechanism 3 and transport mechanism 4 are included. Support 2 is provided on the front and rear sides of base plate 1, cutting mechanism 3 is provided on the right side of support 2, and transport mechanism 4 is provided on the right side of base plate 1.

[0026] When people need to cut the material, the transport mechanism 4 is manually operated to transport the material. When the material is located below the cutting mechanism 3, the cutting mechanism 3 is started, and the cutting mechanism 3 starts cutting the material. After the cutting is completed, the transport mechanism is manually stopped. 4. Then close the cutting mechanism 3 and store the cut materials.

Embodiment 2

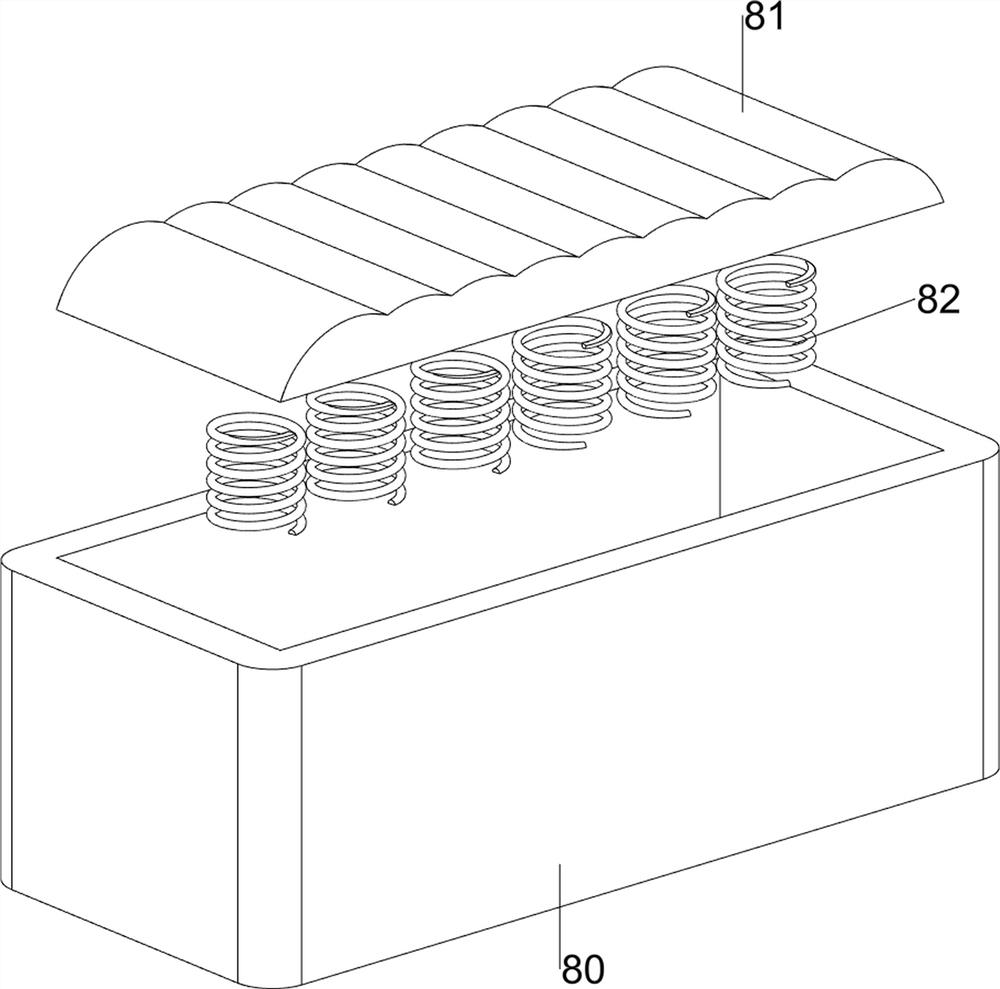

[0028] On the basis of Example 1, such as Figure 2 to Figure 8 As shown, the cutting mechanism 3 includes a mounting plate 30, a support base 31, a servo motor 32, a crank 33, a slide rail 34 and a cutter 35, the mounting plate 30 is connected between the tops of the brackets 2, and the right rear portion of the mounting plate 30 is provided with Slide rail 34, sliding type is connected with cutter 35 on the slide rail 34, and mounting plate 30 right rear parts are provided with support base 31, and support base 31 is provided with servo motor 32, and servo motor 32 output shafts and cutter 35 are all provided with. There are cranks 33, and the cranks 33 are rotatably connected.

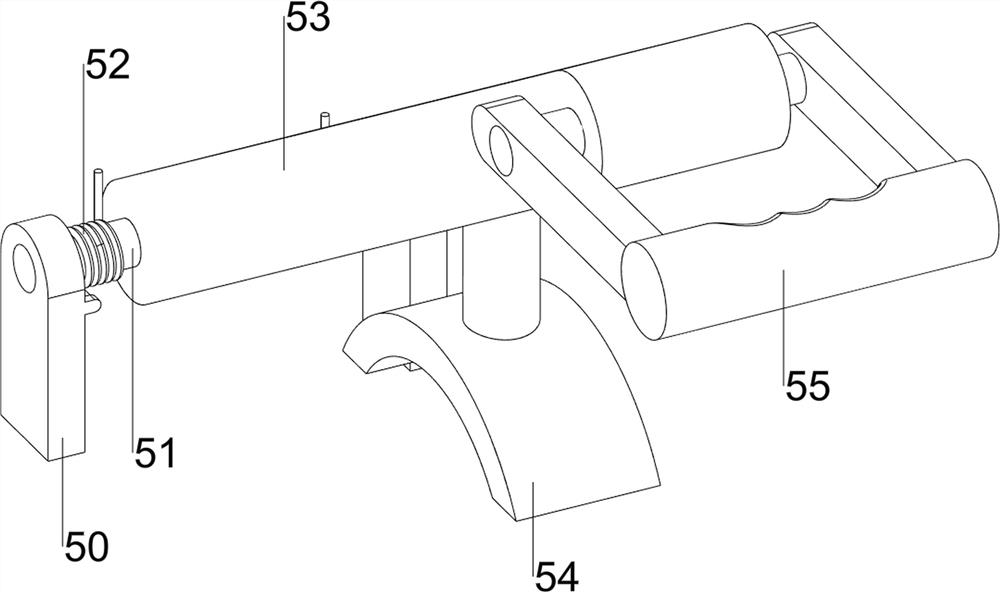

[0029] When people need to cut the material, start the cutter 35, then start the servo motor 32, the servo motor 32 drives the cutter 35 to move up and down in the slide rail 34 through the crank 33, when the servo motor 32 drives the cutter 35 to move upwards, Manually transport the material to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com