A kind of aluminum alloy building formwork forming processing method

A construction formwork and forming processing technology, applied in metal processing equipment, manufacturing tools, auxiliary welding equipment, etc., can solve problems such as inaccurate installation position, inconvenient use process, burns, etc., and achieve the effect of safety assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

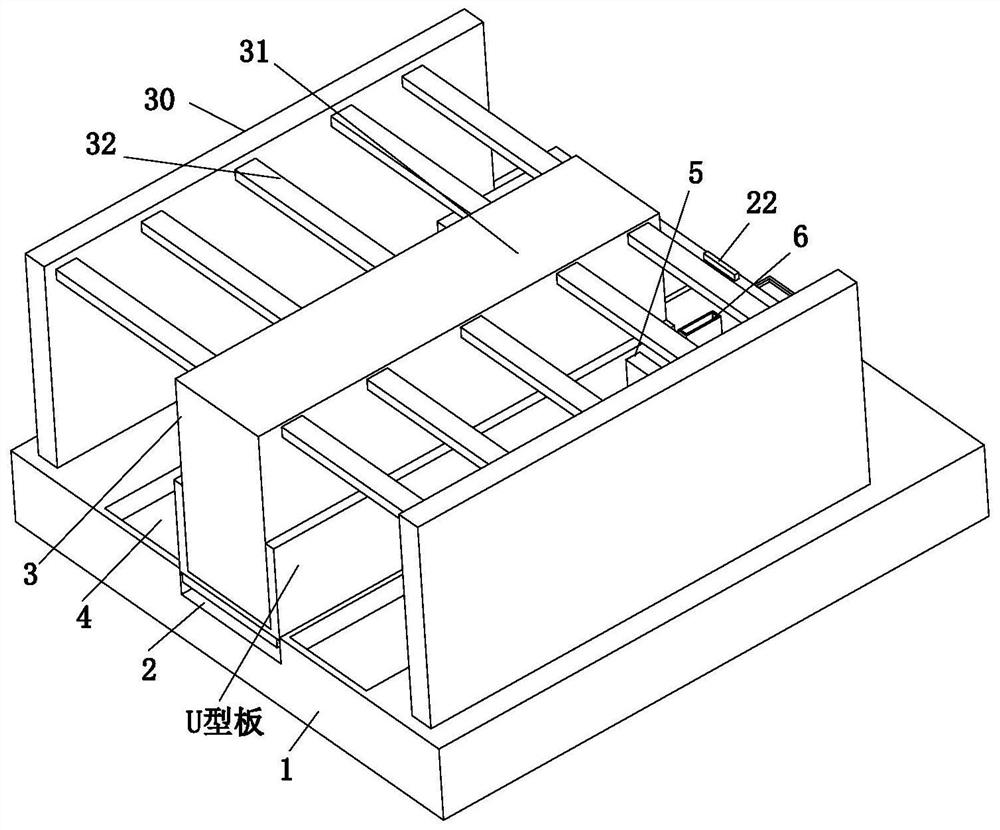

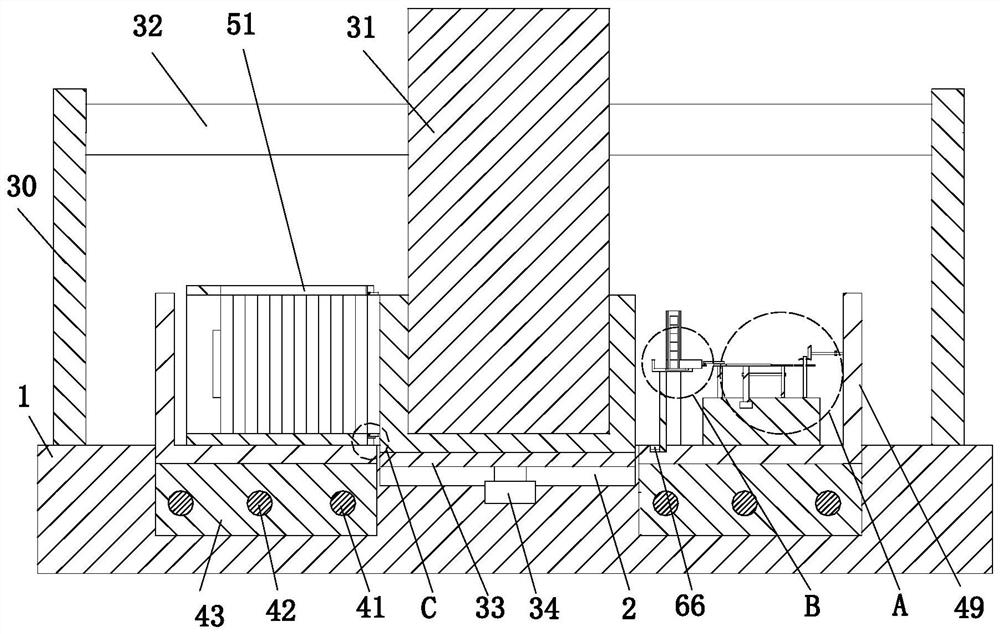

[0037] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention may be implemented in many different ways as predetermined and covered by the claims.

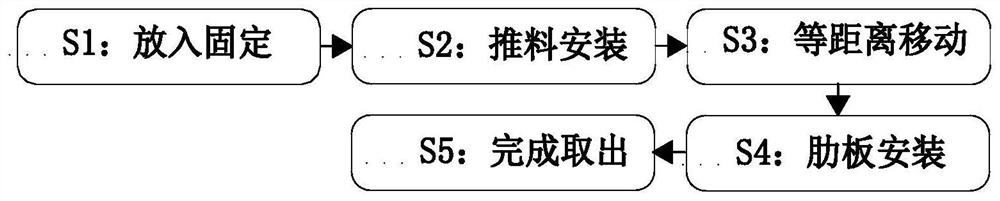

[0038] like Figure 1 to Figure 11 As shown, an aluminum alloy building formwork forming and processing method, which uses an aluminum alloy building formwork forming and processing device, the aluminum alloy building formwork forming and processing device comprises a workbench 1, an indented through groove 2, a pressing mechanism 3, The moving mechanism 4, the panel push-out mechanism 5 and the rib push-out mechanism 6 are as follows:

[0039] S1. Put in and fix: Place the aluminum alloy U-shaped plate into the groove 2 of the workbench 1, and press and fix the U-shaped plate through the pressing mechanism 3;

[0040] S2. Pushing and installation: after step S1, push the panel out through the panel push-out mechanism 5 to abut the vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com