Outer clamping ring pre-tightening mechanism and method

A technology of pre-tightening mechanism and outer pressure ring, which is applied in the direction of wrench, screwdriver, manufacturing tools, etc., can solve the problems of difficult quantifiable torque, lens fragmentation, etc., and achieve the effect of reducing operation time, improving safety, and enhancing operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

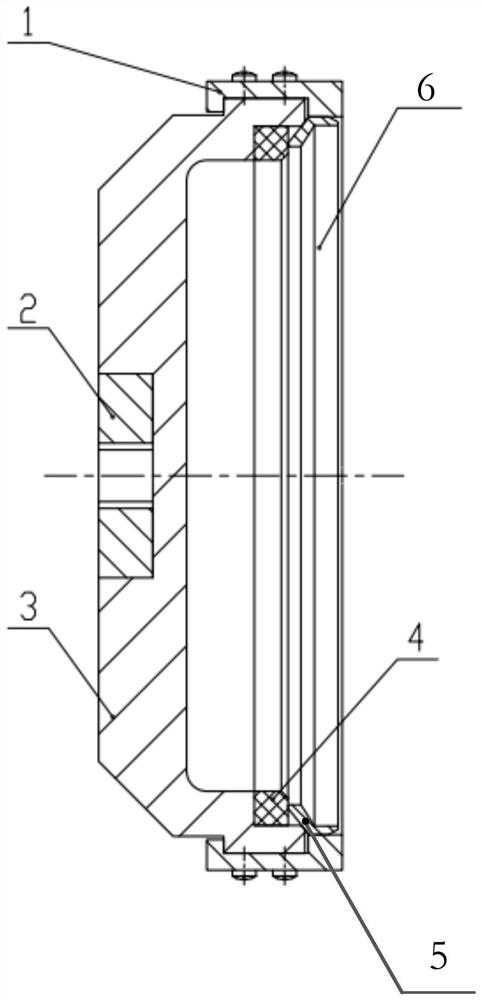

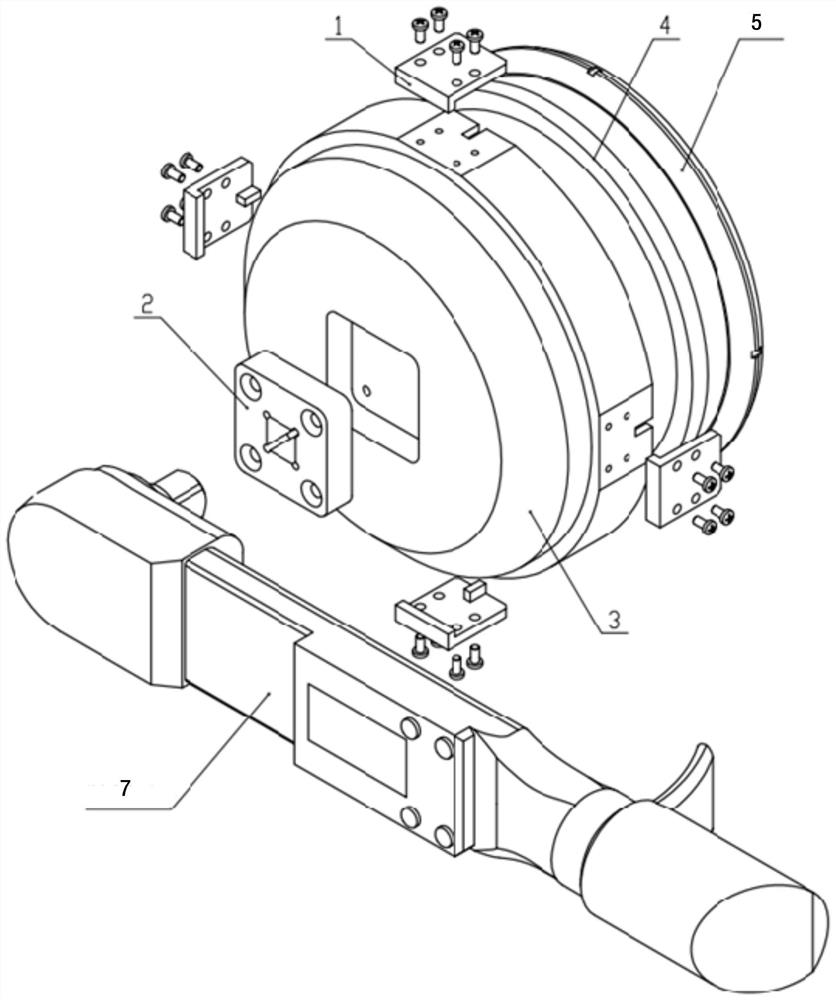

[0021] The outer pressure ring pretensioning mechanism of an embodiment of the present invention is as figure 1 As shown, it includes: a fixed seat 3 provided with a groove; a torque wrench connecting seat 2 arranged in the fixed seat 3; and at least one claw 1 arranged around the fixed seat 3; the claw 1 has a raised portion, and the convex The starting part can cooperate with the outer pressing ring and the groove of the fixing seat. The outer pressure ring pre-tightening mechanism may also include a lens protection ring 4 located inside the fixing seat 3 and arranged on the lens.

[0022] figure 2 show figure 1 Sectional view of the device.

[0023] Specifically, the function of the outer pressure ring 5 is to fix the lens. There are threads on the inner side of the outer pressure ring 5 and the edge of the lens 6. The traditional method is to manually tighten it. This tightening method has both a tangential force along the edge of the lens 6. There is also the force o...

Embodiment approach 2

[0027] This embodiment provides a method for pre-tightening the outer ring, which is realized based on the pre-tightening mechanism for the outer ring in the first embodiment. The method of this embodiment includes: setting the outer pressure ring on the lens; matching the protrusion on the claw with the groove of the outer pressure ring and the fixing seat; installing the torque wrench on the torque wrench connecting seat, and rotating the torque wrench Tighten the outer pressure ring on the lens; adjust the pressure of the outer pressure ring on the lens according to the reading on the torque wrench when turning the torque wrench, so that the reading does not exceed the preset threshold.

[0028] Further, before the above steps are performed, the following steps may also be included: predetermine the torque value required to tighten the outer pressure ring; when the torque wrench is rotated, when the torque wrench reading reaches the torque value, it is determined that the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com