Automatic cleaning machine for gravure rollers of printing machine

An automatic cleaning machine and gravure roller technology, which is applied to printing presses, general parts of printing machinery, printing and other directions, can solve the problems of occupying the effective printing time of the printing press, the long time for cleaning the plate rollers, and the waste of material resources. Achieve the effect of compact structure, lower production cost and lower labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

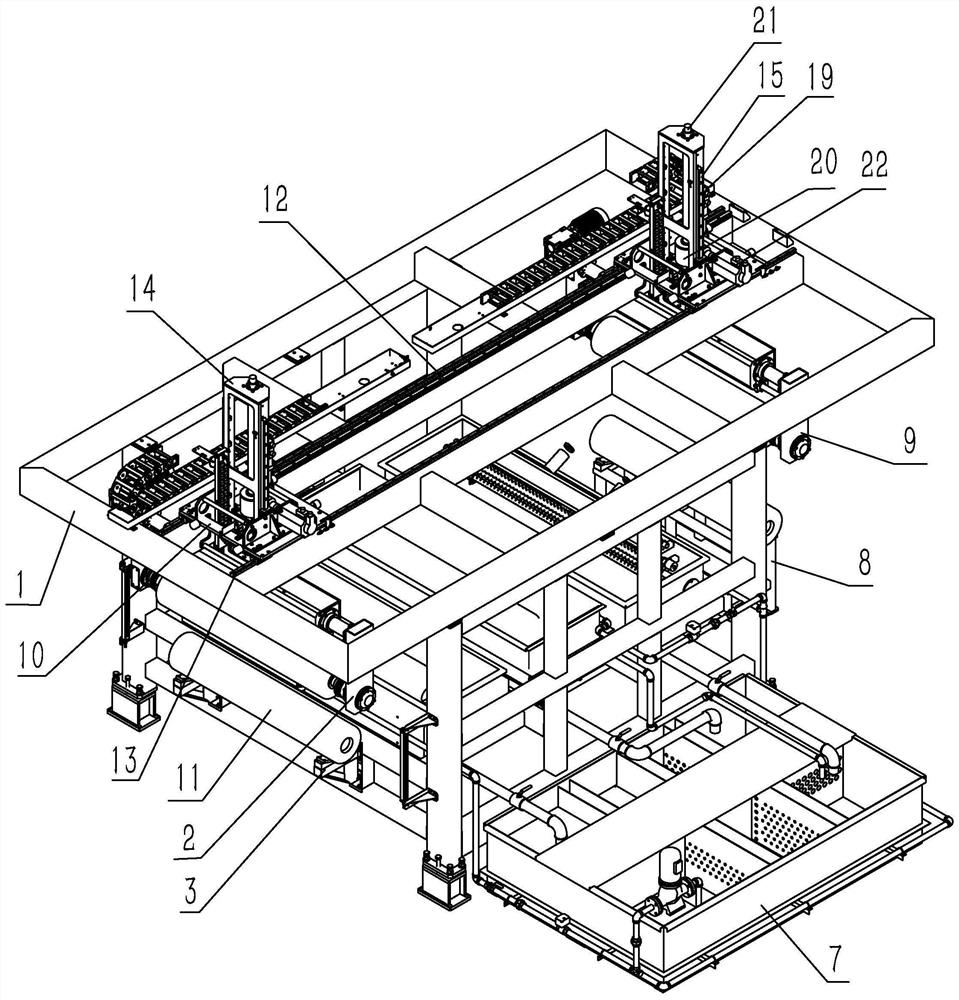

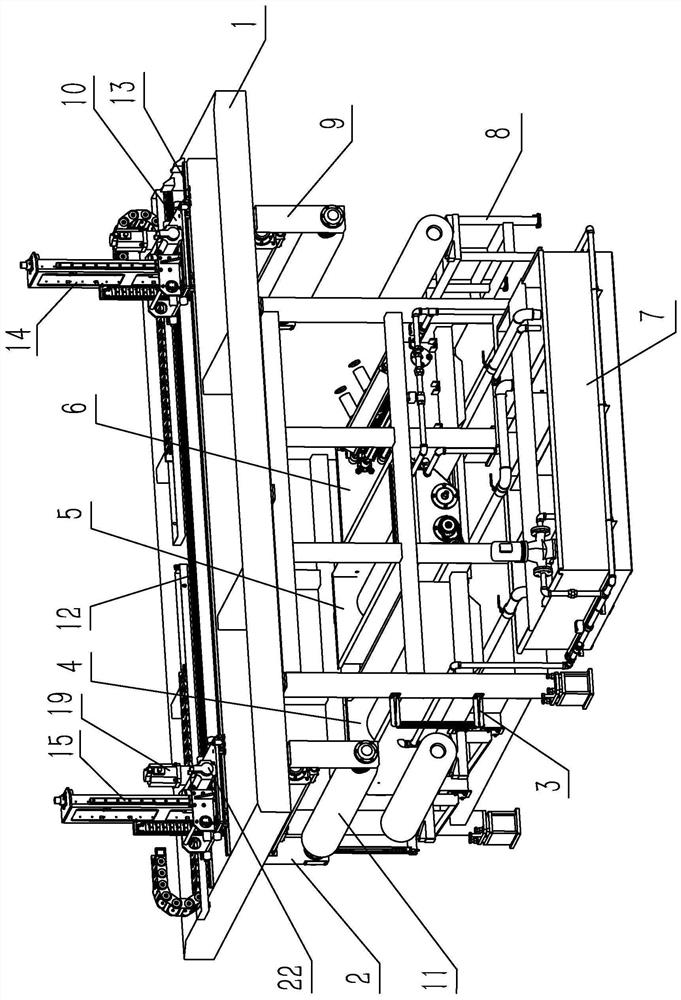

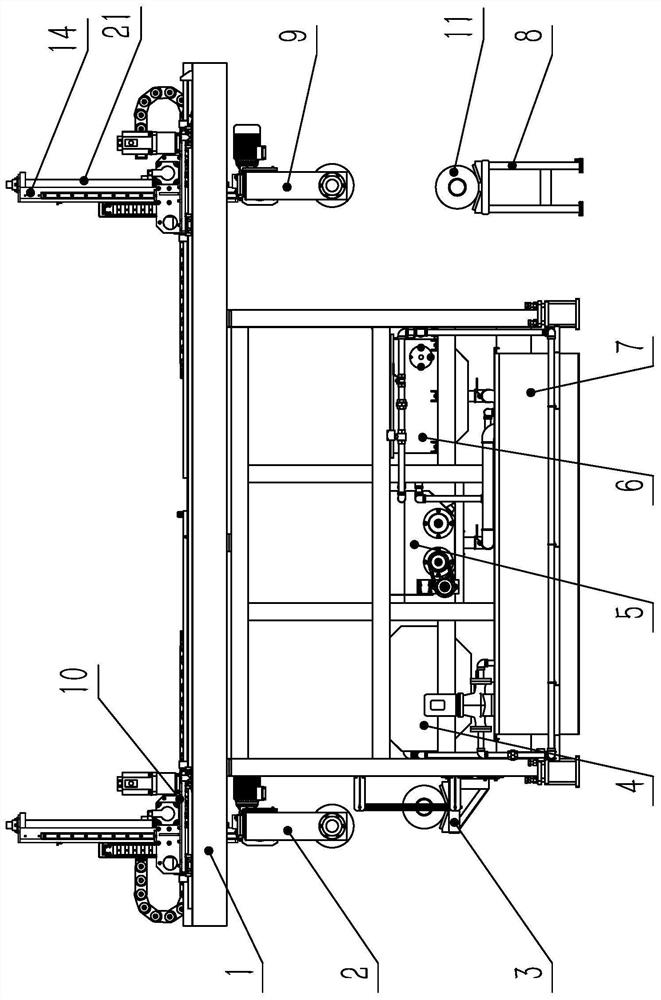

[0046] Further description will be given below in conjunction with the embodiments shown in the accompanying drawings.

[0047] For convenience of description, the image 3 The left side of is left, the right side is right, image 3 The upper side of is up, and the lower side is down.

[0048] Such as Figure 1 to Figure 5The shown automatic gravure roller cleaning machine for printing machines includes a frame 1, two support frames 10, two autorotation mechanical arms (including the first autorotation robotic arm 2 and the second autorotation robotic arm 9), rough cleaning tank 4, ultrasonic Washing tank 5 , cleaning and drying device 6 , feeding transfer frame 3 , transfer table 8 and circulating water treatment equipment 7 . The rough washing tank, ultrasonic plate washing tank and cleaning and drying device are all arranged at the lower part of the frame and arranged in sequence from left to right. The feeding transfer frame is installed on the side of the rough cleani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com