Special textile fabric drying equipment with adjusting function

A technology for textile fabrics and drying equipment, applied in the field of textile fabrics, can solve the problems of easy falling fluff, excessive heating and scorching, and pollution of textile fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] For example figure 1 -example Figure 5 Shown:

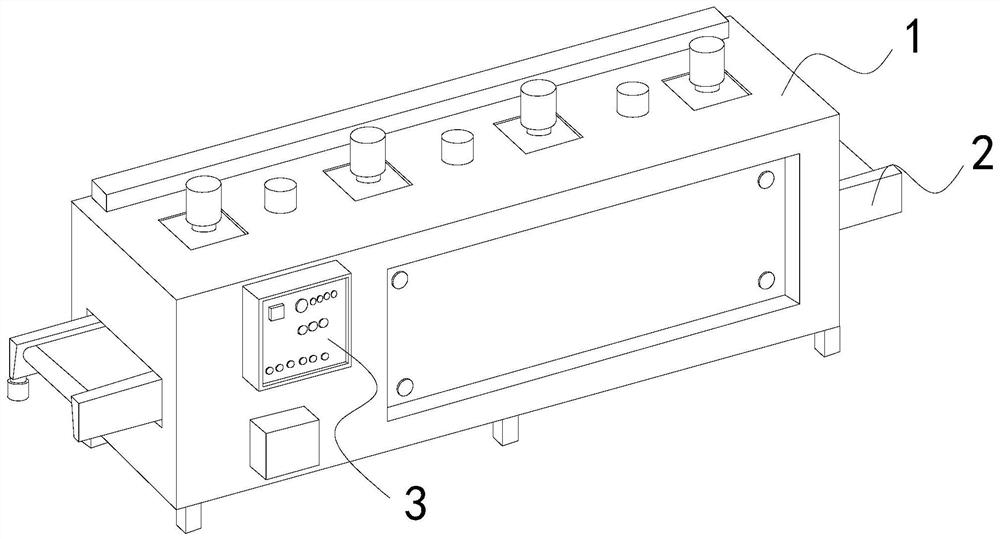

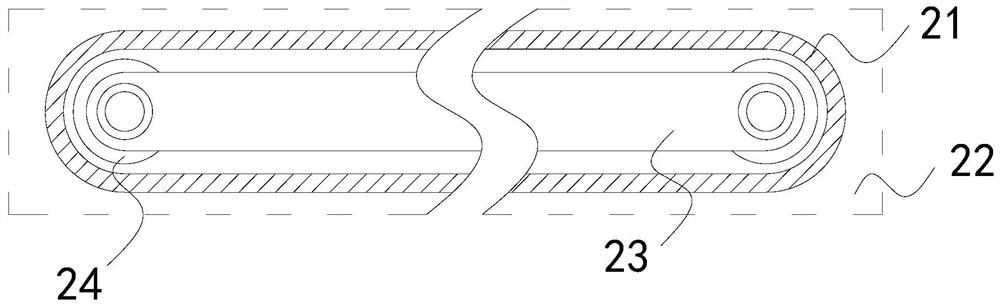

[0027] The present invention provides a special drying equipment for textile fabrics with adjustment function. Its structure includes a heating chamber 1, a transmission platform 2, and a control electric box 3. The control electric box 3 is embedded and fixed at the side of the heating chamber 1. The conveying platform 2 runs through the inner position of the heating chamber 1; the conveying platform 2 includes a conveying belt 21, a partition 22, a linkage rod 23, and a driving roller 24, and the conveying belt 21 is engaged with the external movement of the driving roller 24; The partition plate 22 is fixed on the outer side of the transmission roller 24 , and the linkage rod 23 is installed between the two transmission rollers 24 .

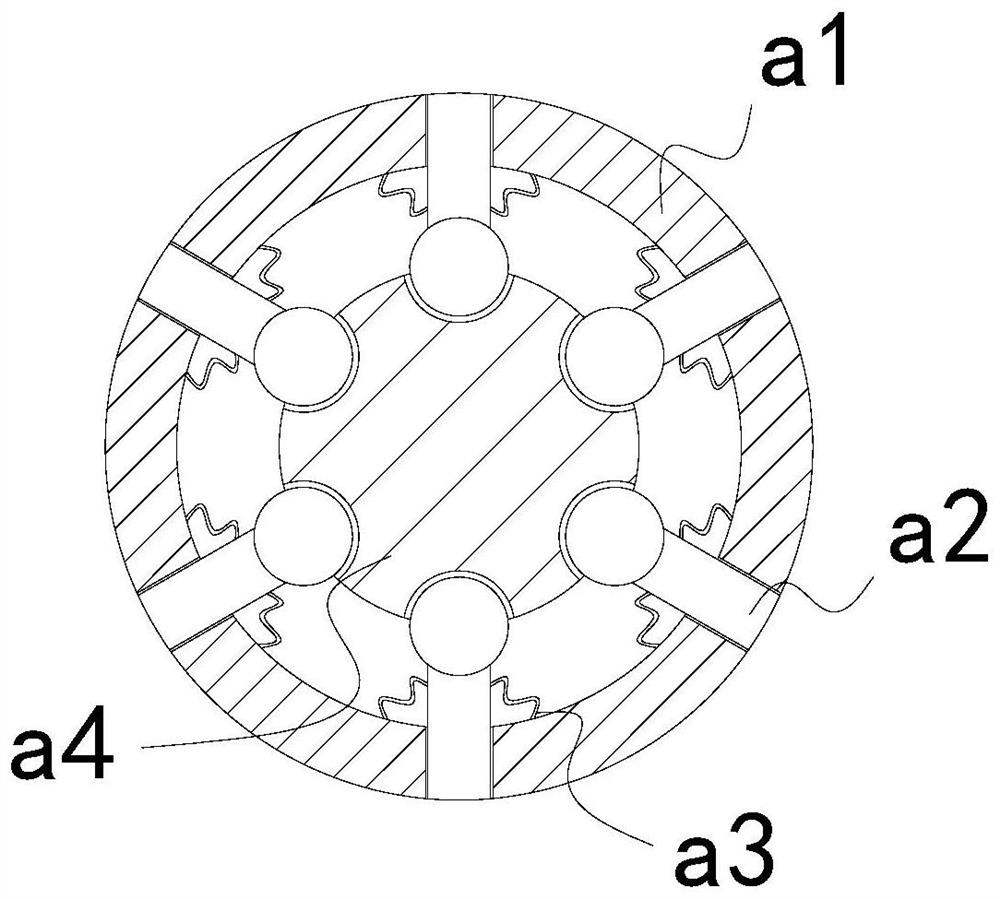

[0028] Wherein, the transmission roller 24 includes a circumscribed roller a1, an external push rod a2, an elastic bar a3, and a fixed block a4. Between the inner side of a1 and the si...

Embodiment 2

[0034] For example Figure 6 -example Figure 8 Shown:

[0035] Wherein, the conveyor belt 21 includes an upper connecting plate c1, a contact reducing groove c2, and an inner connecting belt c3, the upper connecting plate c1 is embedded and fixed on the outer surface of the inner connecting belt c3, and the contact reducing groove c2 and the upper connecting plate c1 As an integrated structure, the contact reducing groove c2 has a triangular groove structure, and the contact area between the upper connecting plate c1 and the hemp textile fabric can be reduced through the contact reducing groove c2.

[0036] Wherein, the upper connection plate c1 includes a conductive strip c11, a plate body c12, and a heat dissipation mechanism c13, the conductive strip c11 runs through the inner position of the plate body c12, and the heat dissipation mechanism c13 and the plate body c12 are an integrated structure, so The plate body c12 is made of copper metal with strong conductivity, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com