Detection method and detection device for section morphology of oil casing real object

A technology of oil casing and real objects, which is applied in the field of detection methods and detection devices for the physical cross-section of oil casing pipes, can solve the problems of extensive procedures, divergent conclusions and analysis, and many personnel, and achieve the problem of time delay and randomness. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

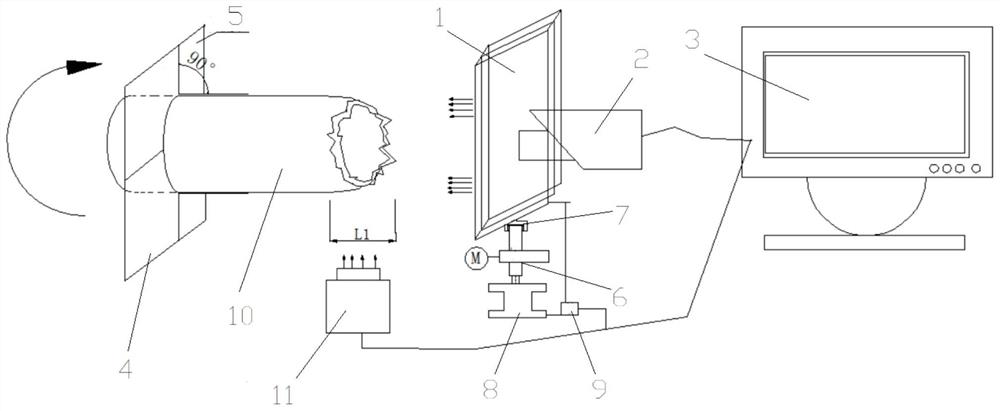

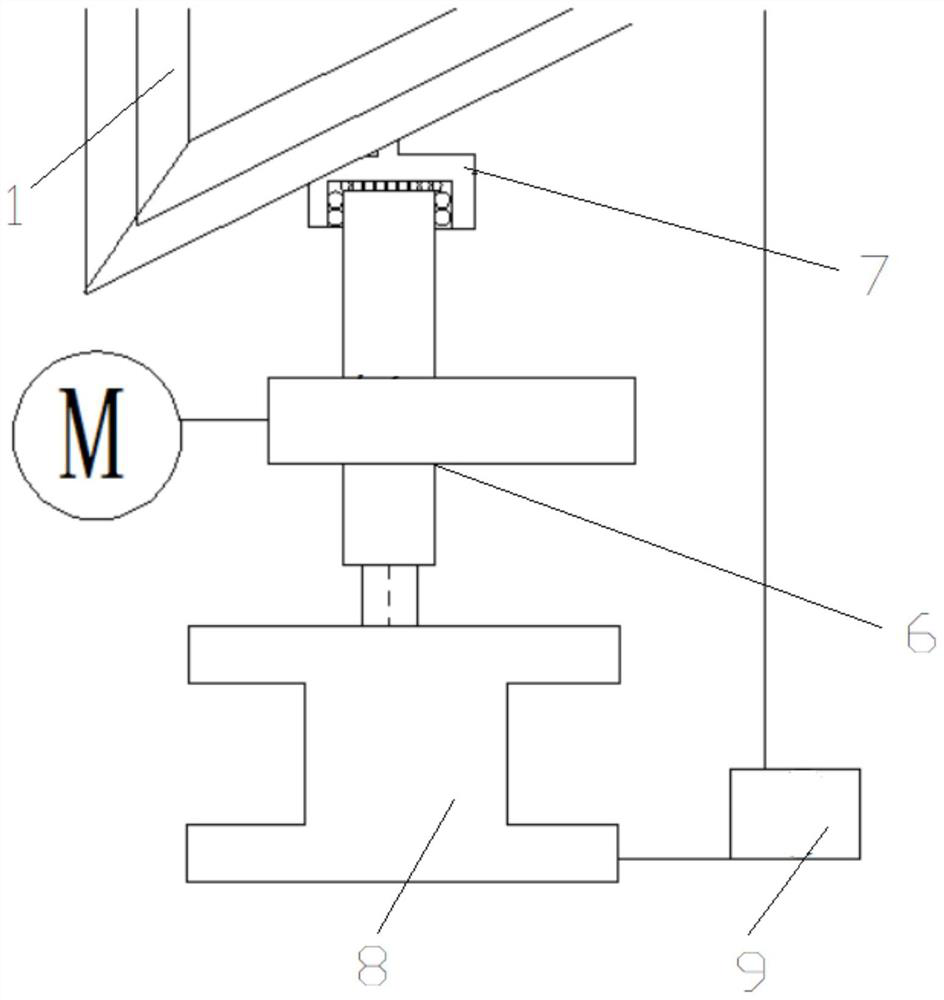

[0028] As a specific embodiment of the present invention, a method for detecting the cross-sectional appearance of an oil casing includes:

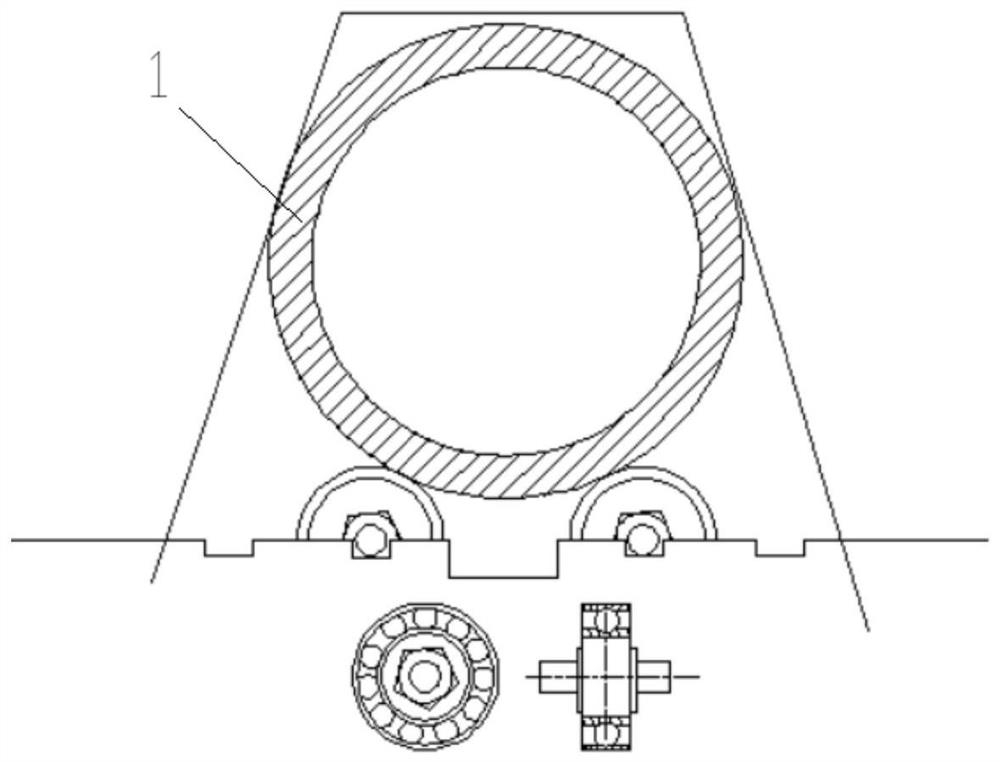

[0029] Directly in front of the end face of the actual fracture of the oil casing, control the laser emitted by the laser rangefinder to move around the end face of the actual fracture of the oil casing, measure the distance from the laser emitting point to the end face of the actual fracture of the oil casing, and obtain the distance set;

[0030] Right in front of the end face of the actual fracture of the oil casing, the image of the end face of the actual fracture of the oil casing is captured by an image acquisition device, and the width of the end face of the actual fracture of the oil casing is obtained according to the image of the end face of the actual fracture of the oil casing; in this embodiment , the image acquisition device is a camera;

[0031] According to the distance set and the width of the end face of the actual fract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com