Inductance coil flattening, cutting and tinning full-automatic equipment based on double rotating discs

A technology of fully automated equipment and inductance coils, applied in coil manufacturing and other directions, can solve problems such as low production efficiency, wasted space, and increase costs, and achieve the effects of improving production efficiency, reducing costs, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

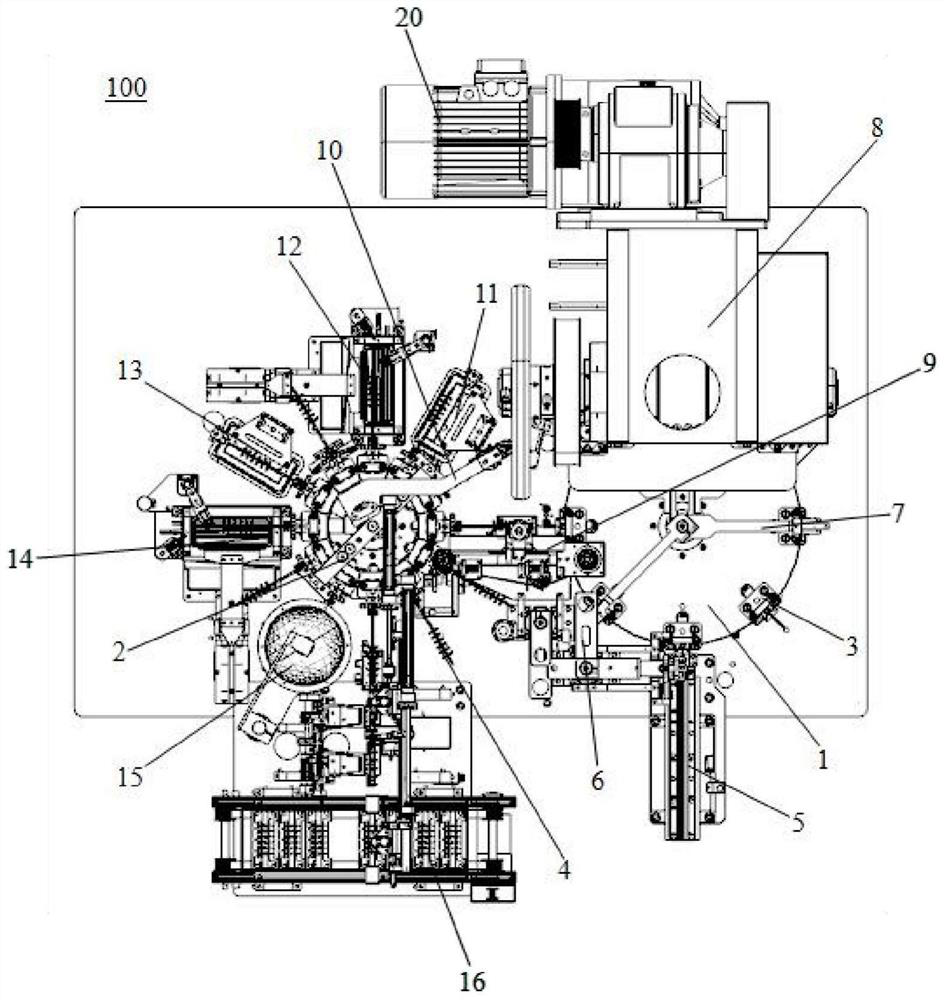

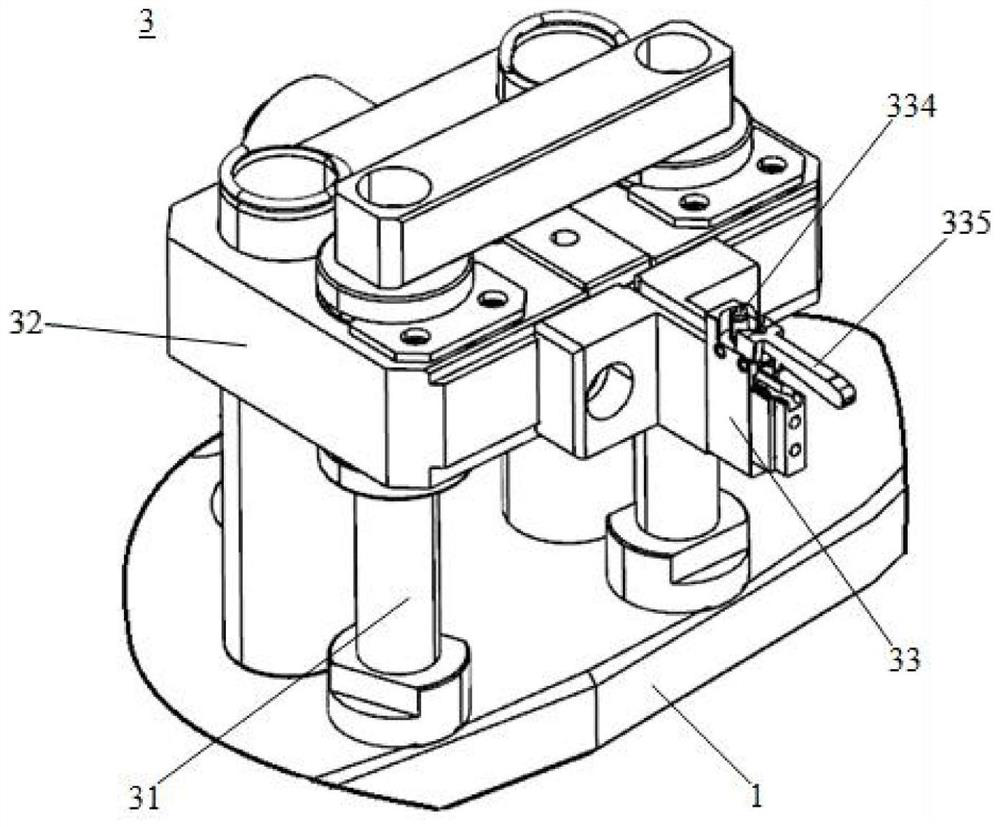

[0055] Please refer to Figure 1-Figure 17 , the present embodiment is a fully automatic equipment 100 for flattening, cutting and dipping of inductance coils based on double turntables. A number of first carrying fixtures 3 and a number of second carrying fixtures 4 on the disk 1 and the second rotating disk 2, a feeding unit 5, a feeding unit 6, and a first position correction unit 7 arranged around the first rotating disk 1 , the flattening and punching integrated mechanism 8, and the transfer and conveyance unit 9 for grabbing the product from the first carrying fixture 3 to the second carrying fixture 4, and the second position correction unit arranged around the second rotating disk 2 10. A first flux supply unit 11 , a first tin supply unit 12 , a second flux supply unit 13 , a second tin supply unit 14 , a detection unit 15 and an automatic waste discharge and collection mechanism 16 .

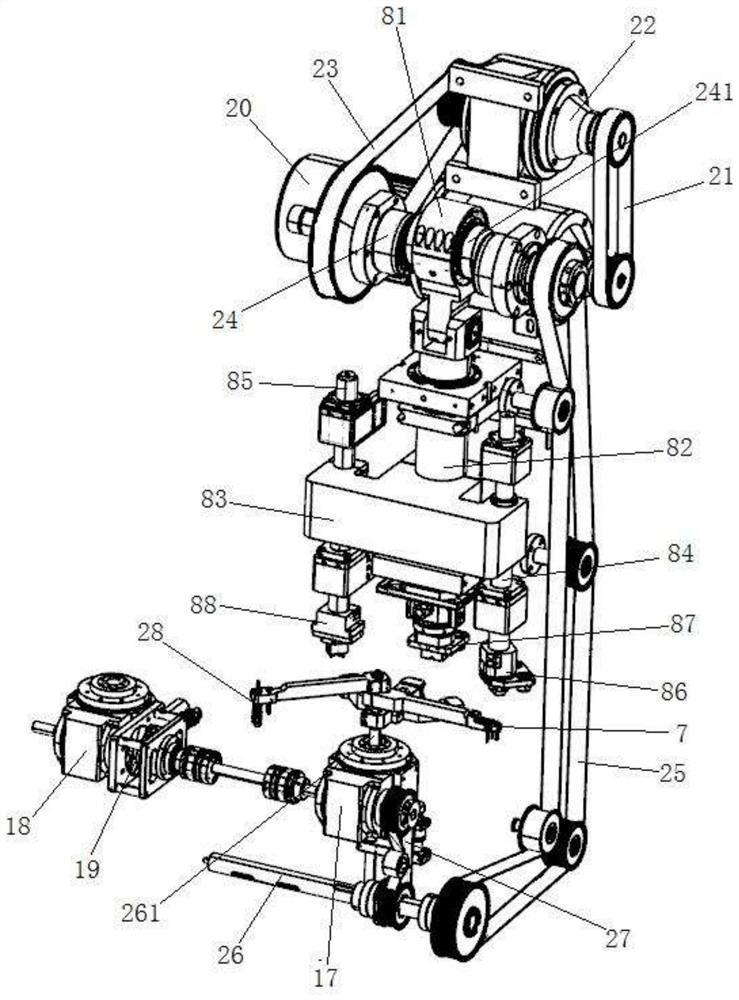

[0056] Please refer to figure 2 , this embodiment also includes a first indexer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com