A fan connector tool-free installation structure

An installation structure and connector technology, which is applied to the parts, connections, coupling devices, etc. of the connection device, can solve the problems of complicated installation process, unfavorable production efficiency, inconvenient maintenance, etc., to ensure the relative positional relationship, convenient application, The effect of easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

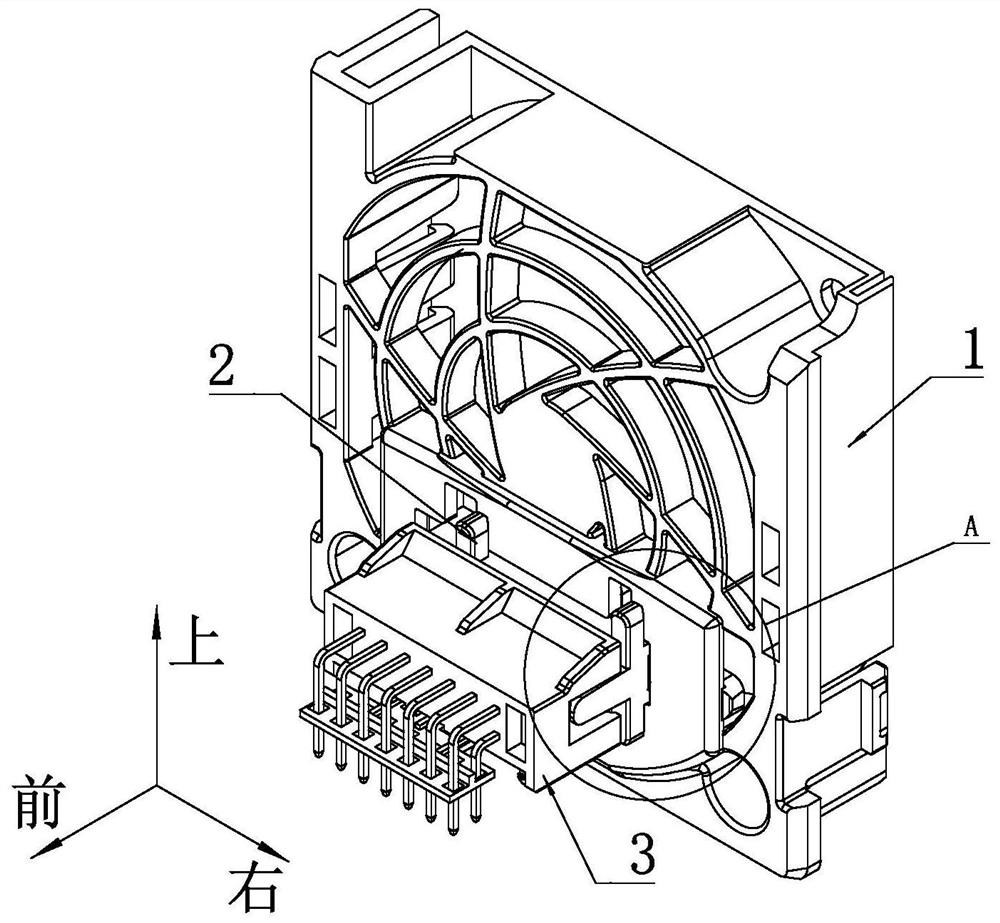

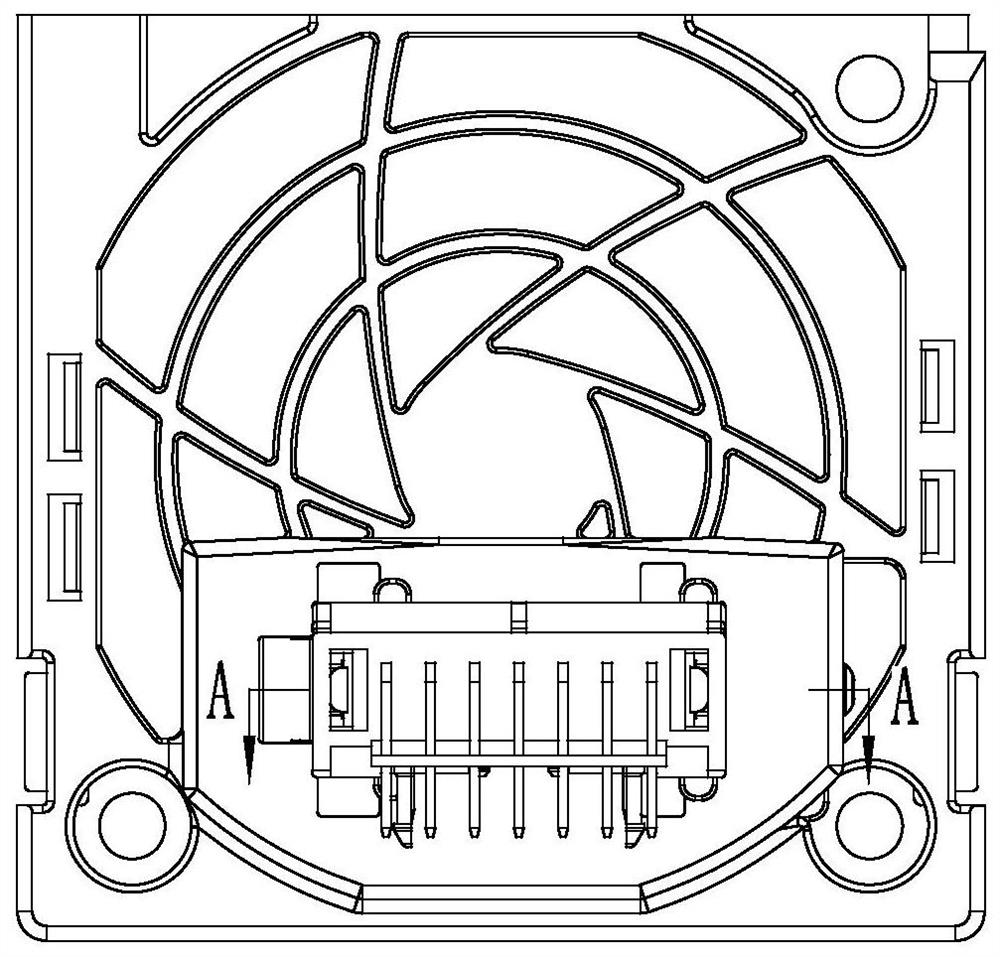

[0051] For the convenience of description, the coordinate system is now defined as figure 1 As shown, the left-right direction is the horizontal direction, the front-rear direction is the vertical direction, and the up-down direction is the vertical direction.

[0052] like figure 1 As shown, a tool-free installation structure for a fan connector includes a fan frame 1 for installing a fan and a fan connector arranged on the fan frame 1, and the fan connector includes a male head 3 and a female head 2, The male header 3 is fixedly arranged on the main board (not shown in the figure), and the female header 2 is fixedly arranged on the fan frame 1 .

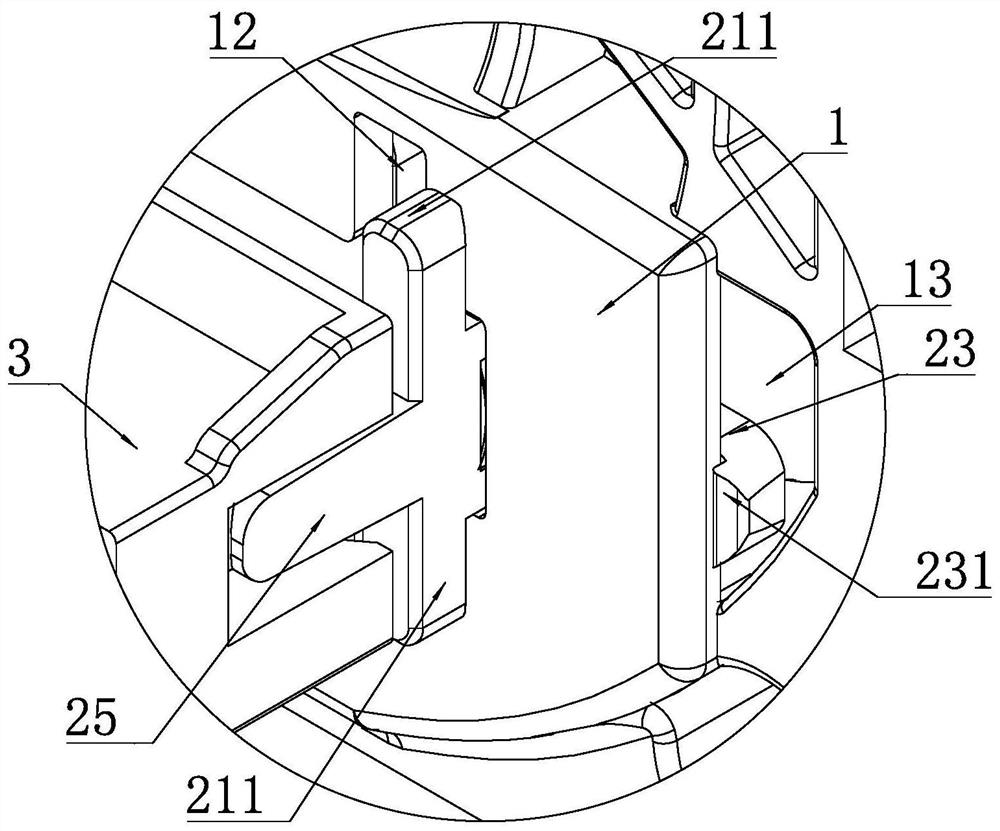

[0053] like Figure 8 As shown, the female connector 2 of the fan connector includes a female connector body 21, and the front side of the female connector body 21 is provided with a plurality of plug posts 26 extending forward in the longitudinal direction. As a specific embodiment, In this embodiment, a plurality of the plug p...

Embodiment 2

[0073] The limiting structure is a square limiting baffle 221 , and the upper side, the lower side, the left side and the right side of the limiting baffle 221 respectively protrude from the outer side of the female head body 21 . The rest of the structure is the same as that of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com