High-voltage line deicing equipment for electric power maintenance

A high-voltage line and electric power technology, which is applied in the field of high-voltage line deicing equipment for power maintenance, can solve the problems of increasing the gravity of high-voltage lines, obstructing high-voltage line deicing, and wooden poles sticking to high-voltage lines, etc., to reduce labor intensity and prevent water from combining with ice. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

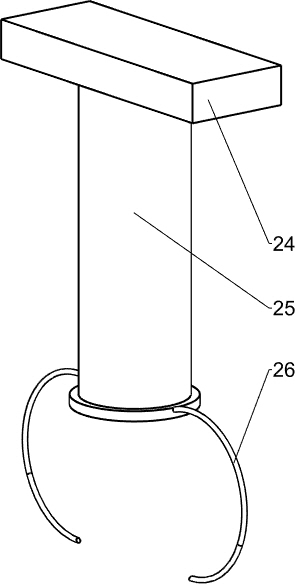

[0031] A high-voltage line deicing equipment for power maintenance, such as figure 1 As shown, it includes a mounting frame 1, a moving mechanism 2 and a deicing mechanism 3, the upper part of the mounting frame 1 is provided with a moving mechanism 2, and the rear part of the left side wall of the mounting frame 1 is equipped with a deicing mechanism 3.

[0032] When it is necessary to de-ice the high-voltage line, the user places the device on the high-voltage line, and then the user starts the moving mechanism 2 to move the device to the left, and the leftward movement of the device can remove the ice on the high-voltage line through the de-icing mechanism 3. After the deicing of the high-voltage line is completed, the user closes the moving mechanism 2, and then the user takes the device off the high-voltage line.

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , figure 2 and image 3 As shown, the moving mechanism 2 includes a mounting plate 201, a reduction motor 202, a first bevel gear 203, a bracket 204, a first rotating shaft 205, a second bevel gear 206, a first pulley 207, a second rotating shaft 208, and a pressure wheel 209 , the second pulley 210 and the belt 211, the mounting plate 201 is connected to the top right side of the mounting frame 1, the top of the mounting plate 201 is provided with a reduction motor 202 by bolts, and the first bevel gear 203 is installed on the output shaft of the reduction motor 202 , the top of the mounting frame 1 on the left side of the mounting plate 201 is provided with a bracket 204, a first shaft 205 is rotatably installed on the bracket 204, a second bevel gear 206 is connected to the first shaft 205, and the second bevel gear 206 is connected to the first bevel The gears 203 mesh, the rear end of the first rotating shaft 205 is eq...

Embodiment 3

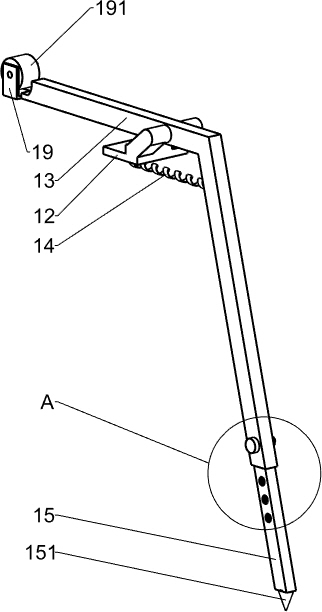

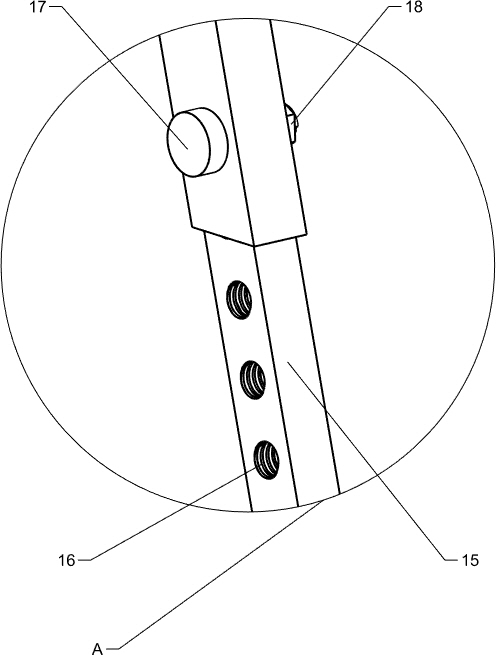

[0039] On the basis of Example 2, such as figure 1 and Figure 5 As shown, it also includes a slider 5, a second spring 6, a third rotating shaft 7, a limit wheel 8, a limit plate 9, a connecting frame 10 and a pull ring 11, and the front and rear sides of the mounting frame 1 on the lower side of the pressing wheel 209 A chute 4 is opened on the wall, and a slider 5 is slidably arranged in the chute 4, and a second spring 6 is fixedly connected between the slider 5 and the chute 4, and a spring 6 is fixedly connected between the two sliders 5 at the front and rear. The third rotating shaft 7, the middle part of the third rotating shaft 7 is equipped with a limit wheel 8, the limit wheel 8 cooperates with the pressure wheel 209, the front and rear sides of the third rotating shaft 7 are all equipped with a limit plate 9, and the two limit plates 9 are installed On the outside of the frame 1, a connecting frame 10 is installed between the outer sidewalls of the two limiting pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com