Absorption tower slurry spray cooling white removal device

A technology of spray cooling and absorption tower, applied in lighting and heating equipment, separation of dispersed particles, chemical instruments and methods, etc., can solve the problems of reducing flue gas treatment efficiency, low flue gas treatment efficiency, affecting the speed of smoke exhaust, etc. , to achieve the effect of improving flue gas treatment efficiency, heat exchange effect and dewhitening effect, and thorough flushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the examples, but not as a basis for limiting the present invention.

[0031] Example.

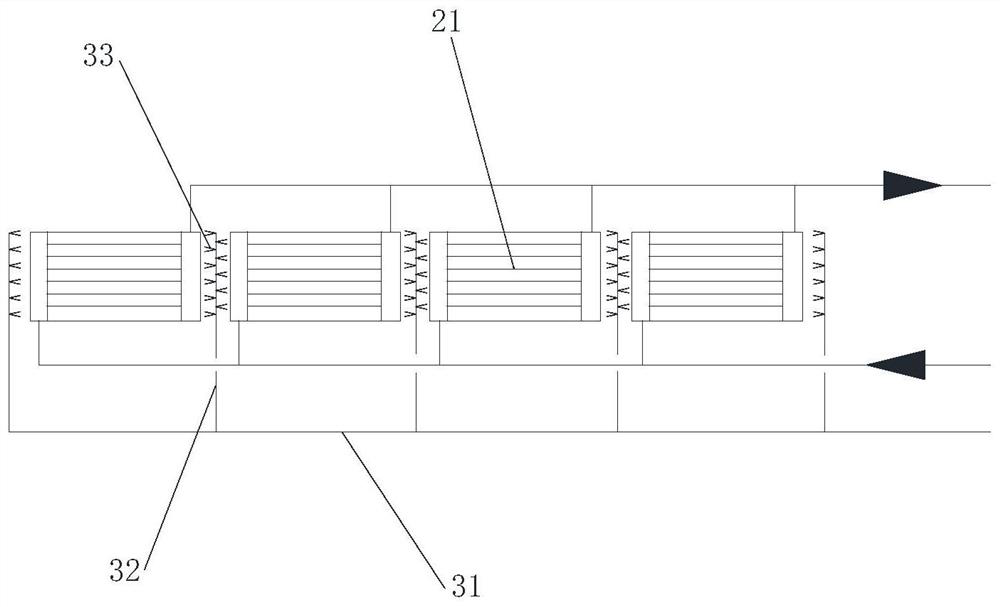

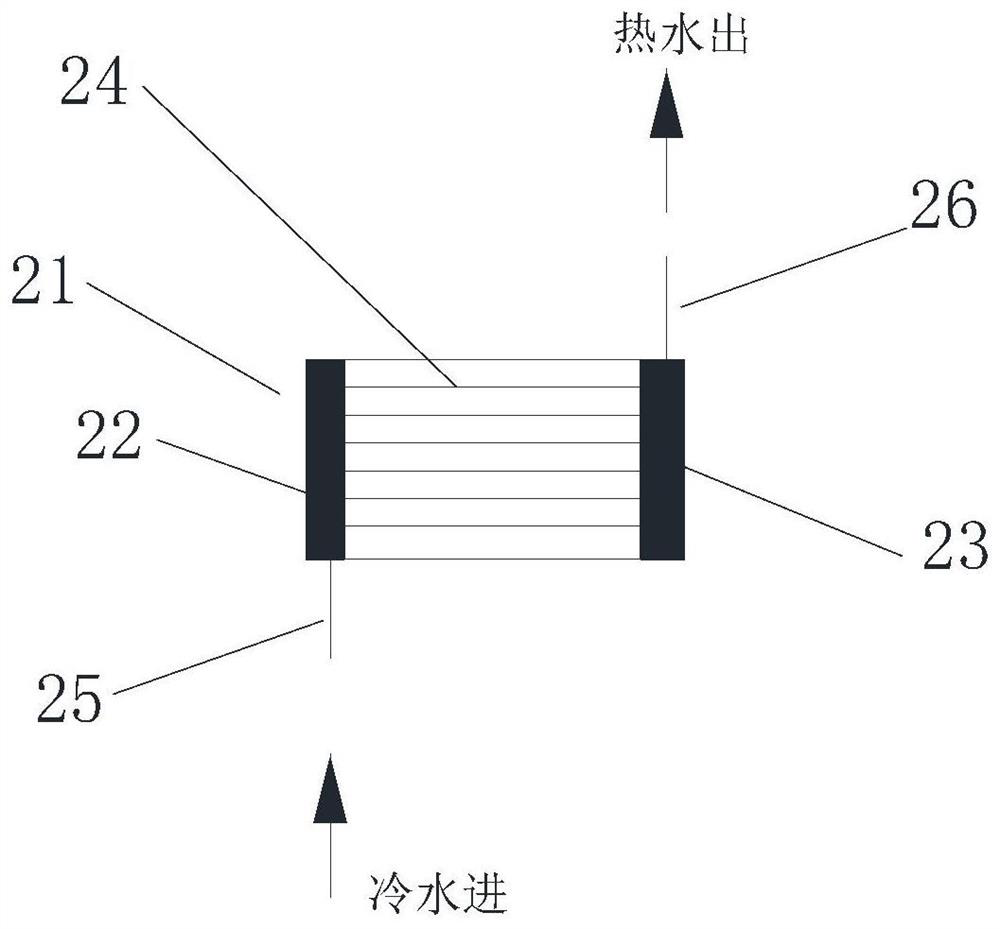

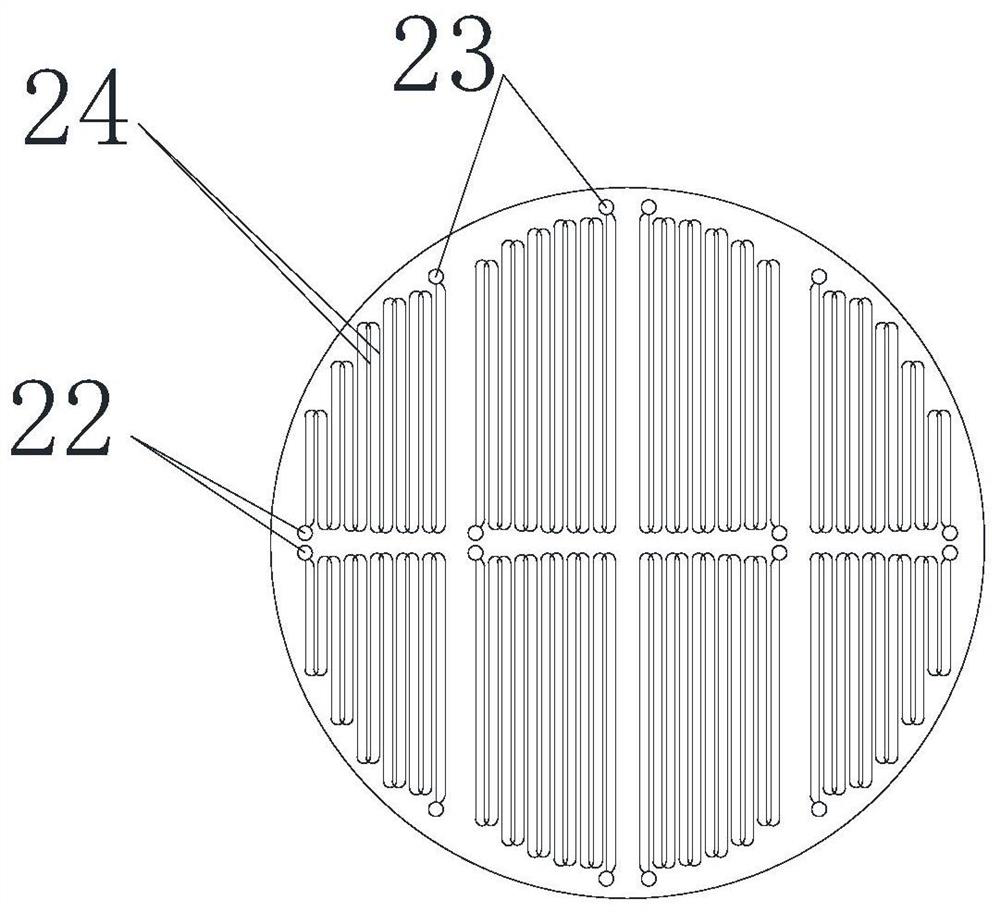

[0032] Such as Figure 1-6 As shown, the absorption tower slurry spray cooling dewhitening device includes a slurry cooling plate 2 composed of several condensation modules 21 installed below the spray layer 4 and a flushing device 3, and the condensation module 21 includes an inlet header 22 and an outlet The header 23, the inlet header 22 and the outlet header 23 are provided with several staggered heat exchange coils 24; the flushing device 3 includes a flushing main pipe 31, and several deep slurry cooling plates are arranged on the flushing main pipe 31 2 and located on both sides of the condensation module 21, the flushing branch pipe 32 is provided with a number of flushing nozzles 33 facing the condensation module 21. The flushing branch pipe 32 goes deep into the slurry cooling plate 2 for flushing, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com