Furnace slag treatment intelligent factory based on Industry 4.0

A slag and industrial technology, applied in the field of slag processing intelligent chemical plant, can solve the problems of increasing processing time, device damage, reducing processing efficiency, etc., and achieve the effect of increasing work efficiency and realizing processing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

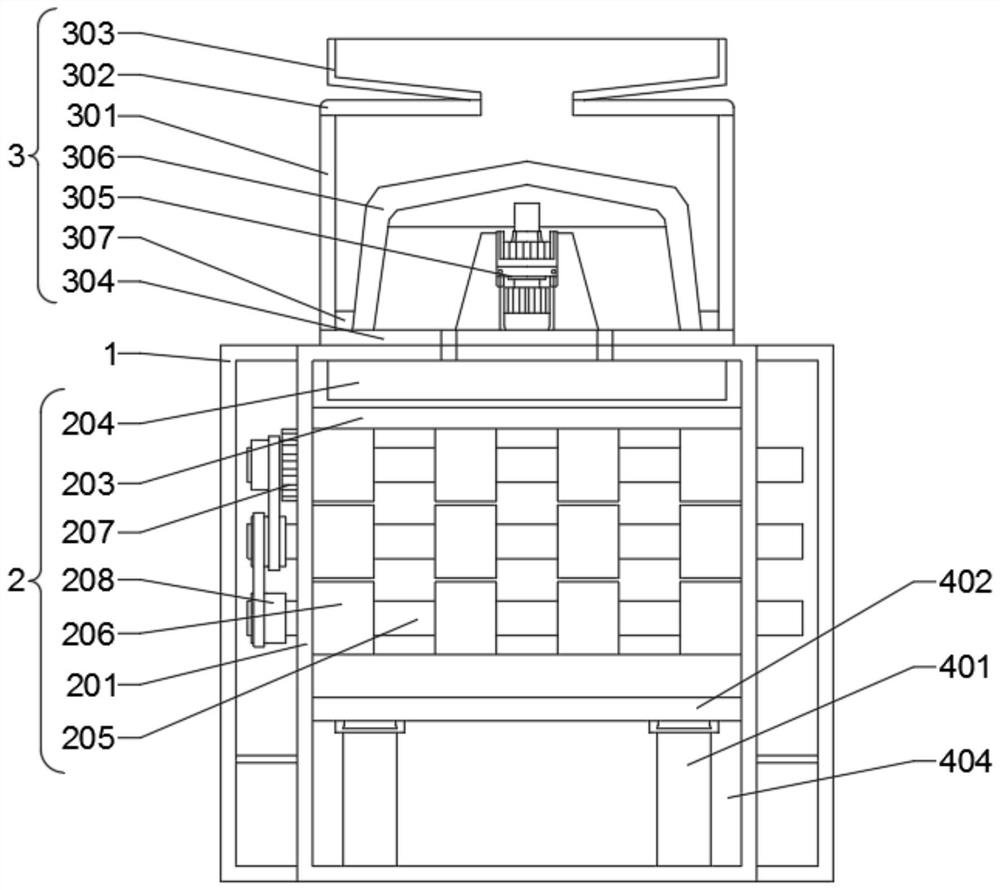

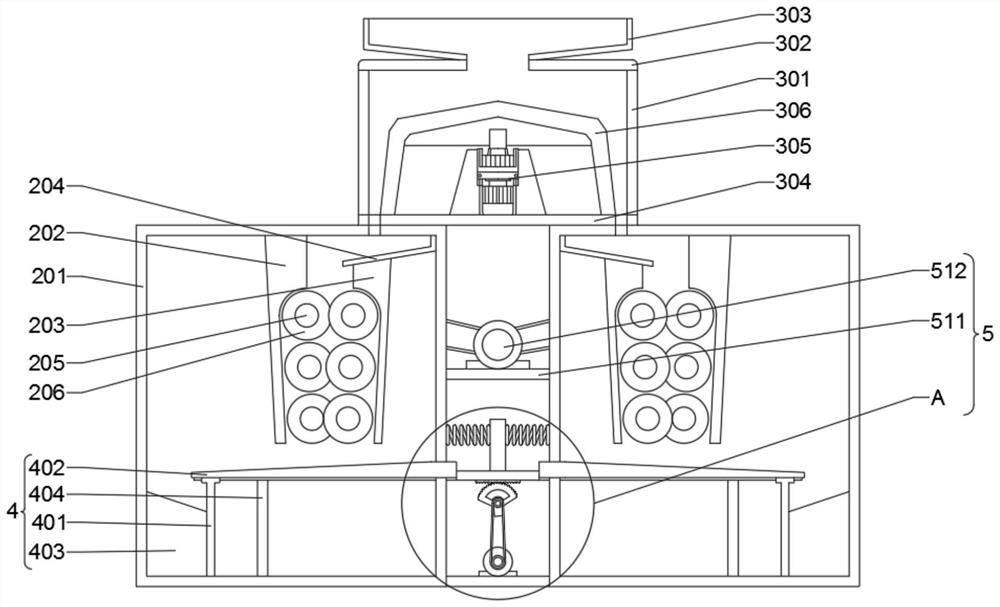

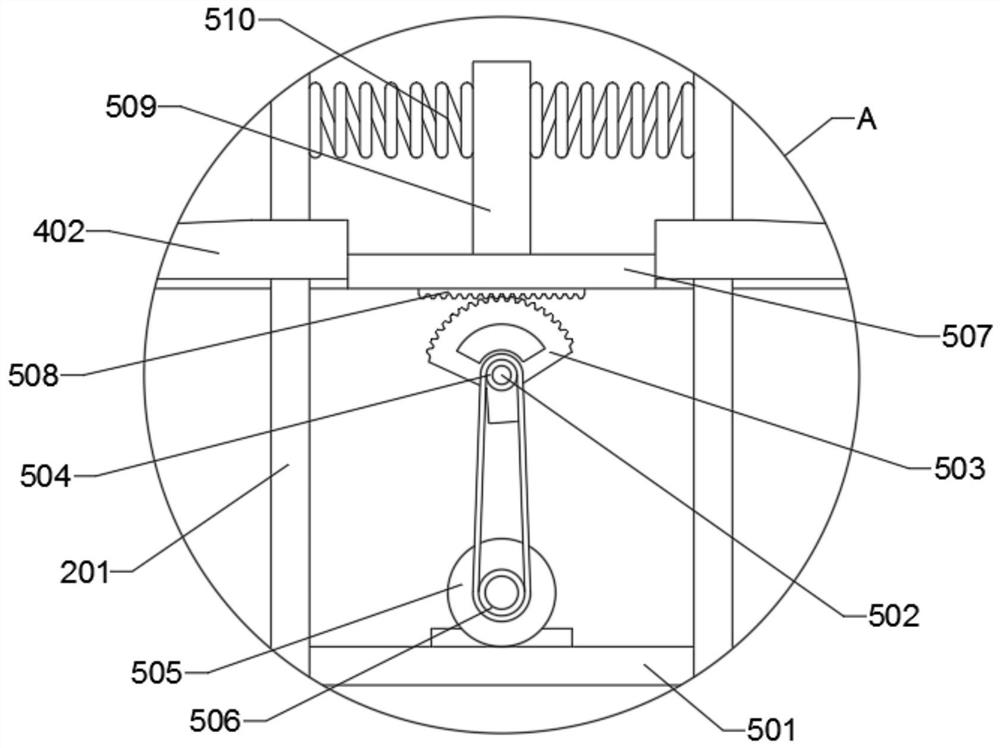

[0030] Example 1, such as Figure 1-4 As shown, the present invention provides an intelligent chemical plant for slag processing based on Industry 4.0, including a protective shell 1, two protective shells 1 are arranged in total, two processing mechanisms 2 are fixed between the front and rear surfaces of the two protective shells 1, and the two A crushing mechanism 3 is fixed between the tops of the two processing mechanisms 2, a filter mechanism 4 is fixed on the inner bottom surfaces of the two processing mechanisms 2, and a power mechanism 5 is arranged between the outer surfaces of one side of the two processing mechanisms 2;

[0031] The crushing mechanism 3 includes a first housing 301, the top of the first housing 301 is fixed with a cover plate 302, the top of the cover plate 302 is fixed with a feeding cylinder 303, the top center of the cover plate 302 is provided with a communication hole, and the communication hole The top of the first housing 301 is fixed with a...

Embodiment 2

[0033] Example 2, such as Figure 1-4 As shown, the processing mechanism 2 includes a second housing 201, the top of the second housing 201 is provided with a material inlet, and the top of the material inlet extends to the outside of the bottom plate 304, between the front and rear inner surface walls of the second housing 201 The first baffle plate 202 is welded, the second baffle plate 203 is welded on the side away from the first baffle plate 202 between the front and rear inner surface walls of the second housing 201, and the top of the second baffle plate 203 is welded with a fixing plate 204, Six first metal rods 205 are arranged between the front and rear inner surface walls of the second housing 201 near the first baffle plate 202 , and both ends of the six first metal rods 205 penetrate to the outside of the second housing 201 , the six first metal rods 205 are divided into two groups, and the outer surfaces of one group of three first metal rods 205 are equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com