Waste recycling device for energy-saving building construction

A technology for waste recycling and building construction, which is applied in the direction of separating solids from solids with airflow, solid separation, and screening, etc. It can solve the problems of poor screening effect and insufficient fine screening effect of building materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

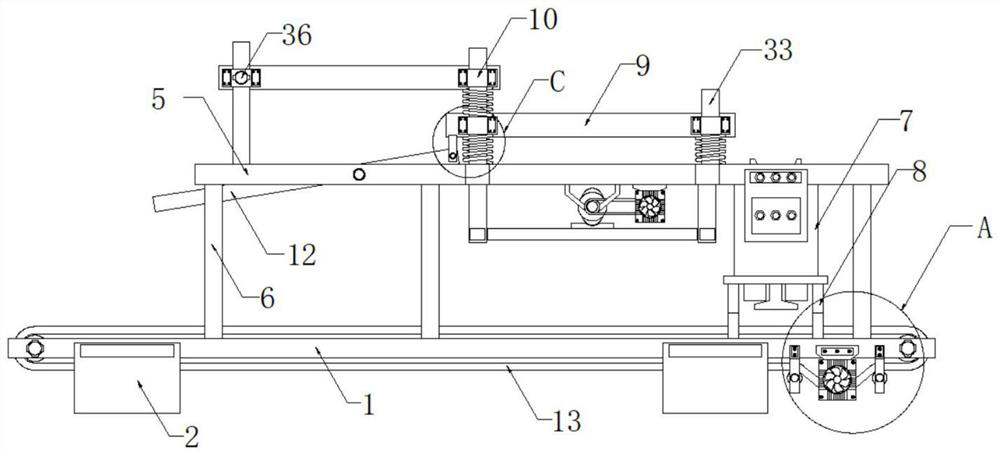

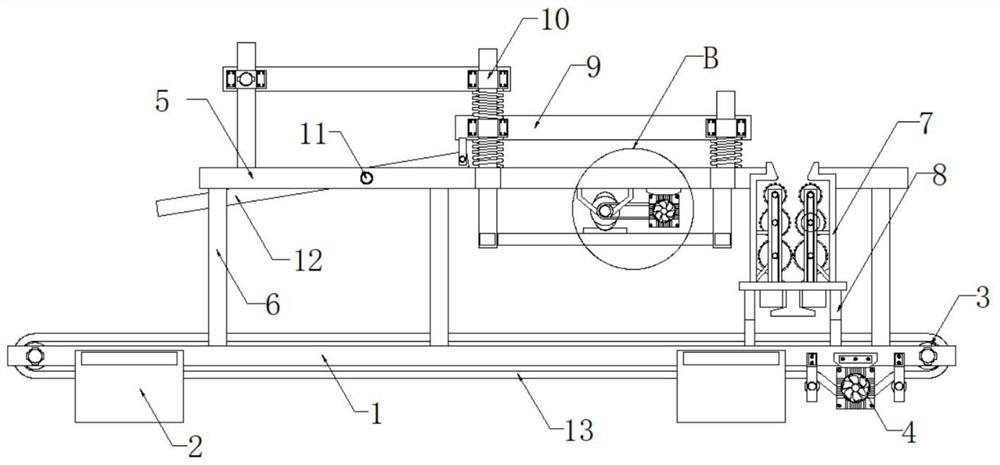

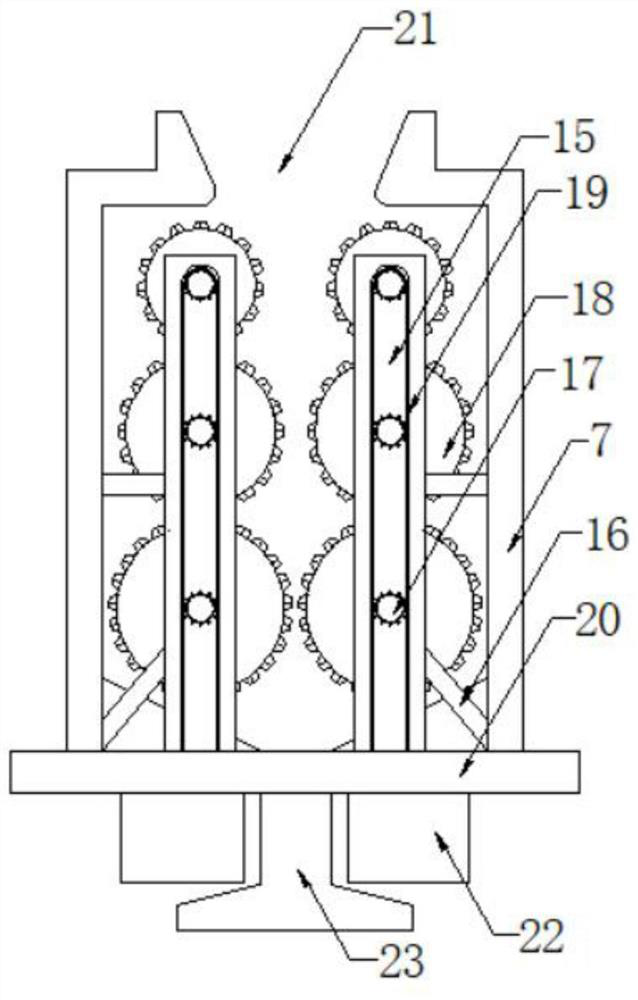

[0028] Embodiment one, by Figure 1-7Given, the present invention comprises support base plate 1, and the top of support base plate 1 is provided with sieve support 5, and the inner rotation socket of support base plate 1 is provided with two drive drums 3, and two drive drums 3 are centered on the axle center of support base plate 1 The center is symmetrically distributed, the outer rotation of the two drive rollers 3 is sleeved with a transmission belt 13, the inner wall of the transmission belt 13 is in contact with the outer wall of the supporting base 1, and the bottom of the supporting base 1 is fixedly installed with the first motor 4, the first motor 4 The output end of the output end is in contact with the inner wall of the transmission belt 13 through the rotating shaft round rod, and four rotating brackets 24 are fixedly installed on the bottom of the support base plate 1, and every two corresponding rotating brackets 24 form a group, and the inside of each rotating ...

Embodiment 2

[0029] Embodiment 2, on the basis of Embodiment 1, the insides of the two sleeves 10 are movably connected with connecting rods 36, and one ends of the two connecting rods 36 are movably connected to the inside of the screening plate 9 , so that one end of the screening plate 9 can be fixed on one side of one of the supporting frames 6 .

Embodiment 3

[0030] Embodiment three, on the basis of embodiment one, the inside of sieve plate 9 is provided with through-hole groove 37, and the inner wall of through-hole groove 37 is fixedly installed with several sorting plates 14, and several sorting plates 14 are evenly distributed Inside the through hole groove 37 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com