Dry washing type cleaner for glass cutting pipe

A technology for glass cutting tubes and cleaners, which is applied in the field of dry cleaning cleaners for glass cutting tubes. It can solve the problems of low cleaning efficiency and unsatisfactory ultrasonic cleaning effect, and achieve good results, save energy consumption, and improve cleaning efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

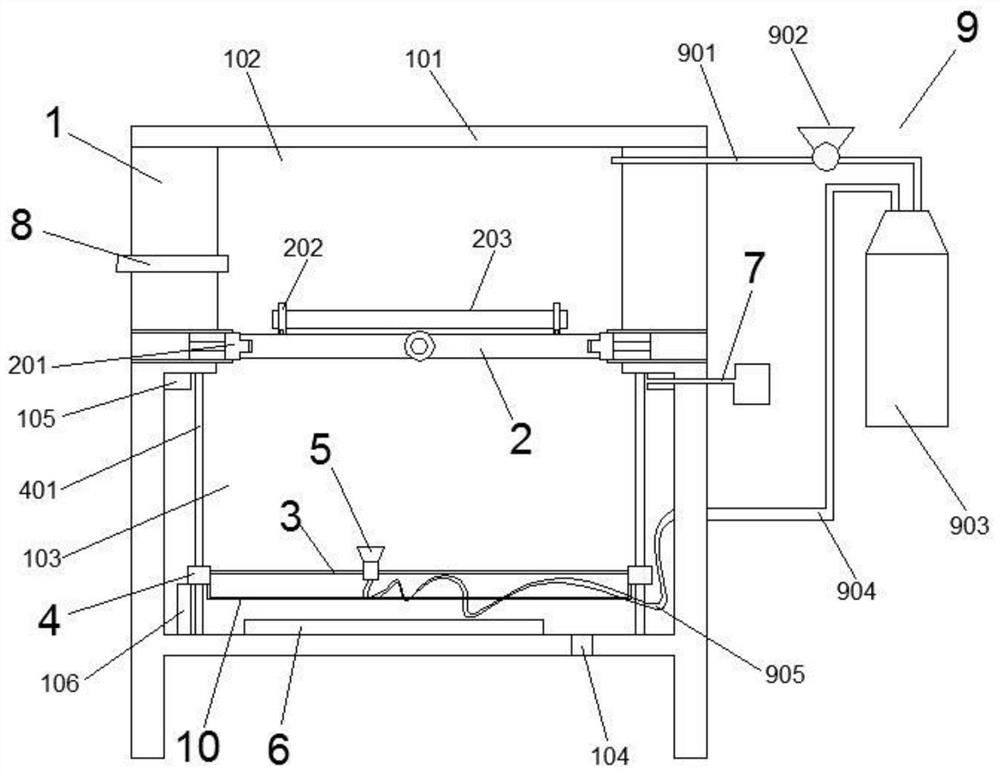

[0037] Such as figure 1 As shown, a dry-cleaning cleaner for vitrified tubes includes a cleaning box 1, the top of the cleaning box 1 is provided with an openable closed end cover 101, and the inside of the cleaning box 1 has a reversible carrying platform 2. The reversible carrying platform 2 cooperates with the retractable clamps 201 on both sides of the cleaning box 1 to divide the inside of the cleaning box 1 into an upper freezing chamber 102 and a lower heating chamber 103, and several groups are distributed on one surface of the reversible carrying platform 2 Fixtures 202, each set of fixtures 202 clamps and fixes a glass cutting tube 203, and makes it turn over with the reversible carrier 2;

[0038] The vitrified tube 203 clamped by the clamp 202 is first in the upper freezing chamber 102. At this time, the upper freezing chamber 102 uses the freezing device 8 therein to reduce its internal temperature to minus 10-20°C, so that the vitrified tube 203 The residual dir...

Embodiment 2

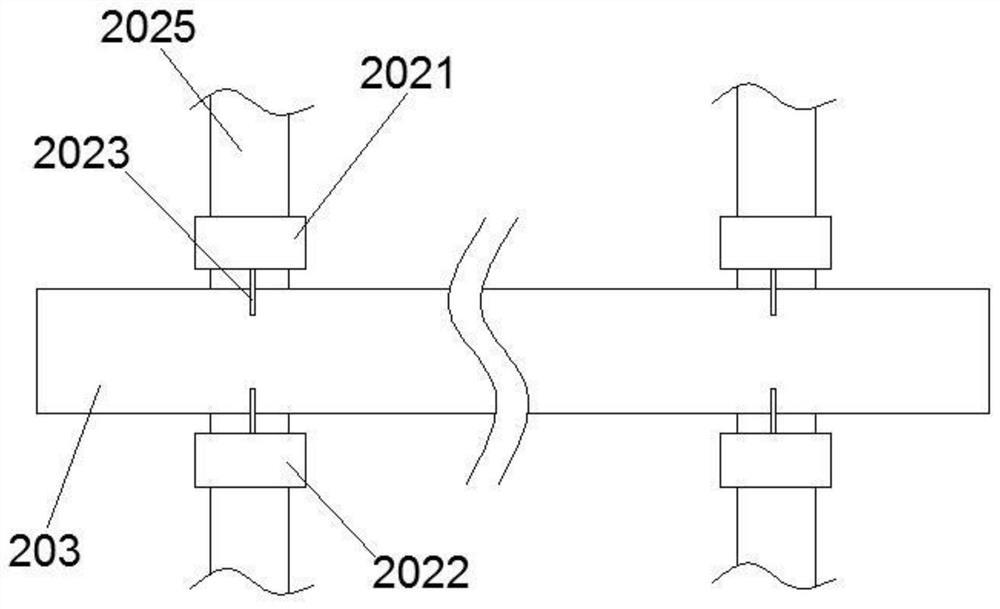

[0045] This embodiment is an optimization scheme based on Embodiment 1, its main structure is the same as that of Embodiment 1, and the improvements are as follows: Figure 2-4 As shown, each set of clamps 202 includes two symmetrical clamping units, each clamping unit includes a symmetrically arranged fixed clamping plate 2022 and a movable clamping plate 2021, and the fixed clamping plate 2022 and the movable clamping plate The opposite side of 2021 has an arc-shaped clamping knife 2023, and the bottom of the movable clamping plate 2021 is slidably arranged on the slide rail 2025 on the surface of the reversible carrying platform 2, between the fixed clamping plate 2022 and the movable clamping plate 2021. A manual adjustment bolt 2024 is arranged between them, and the distance between the fixed clamping plate 2022 and the movable clamping plate 2021 is adjusted by turning the manual adjusting bolt 2024, thereby completing the clamping of the vitrified tube 203.

[0046] In ...

Embodiment 3

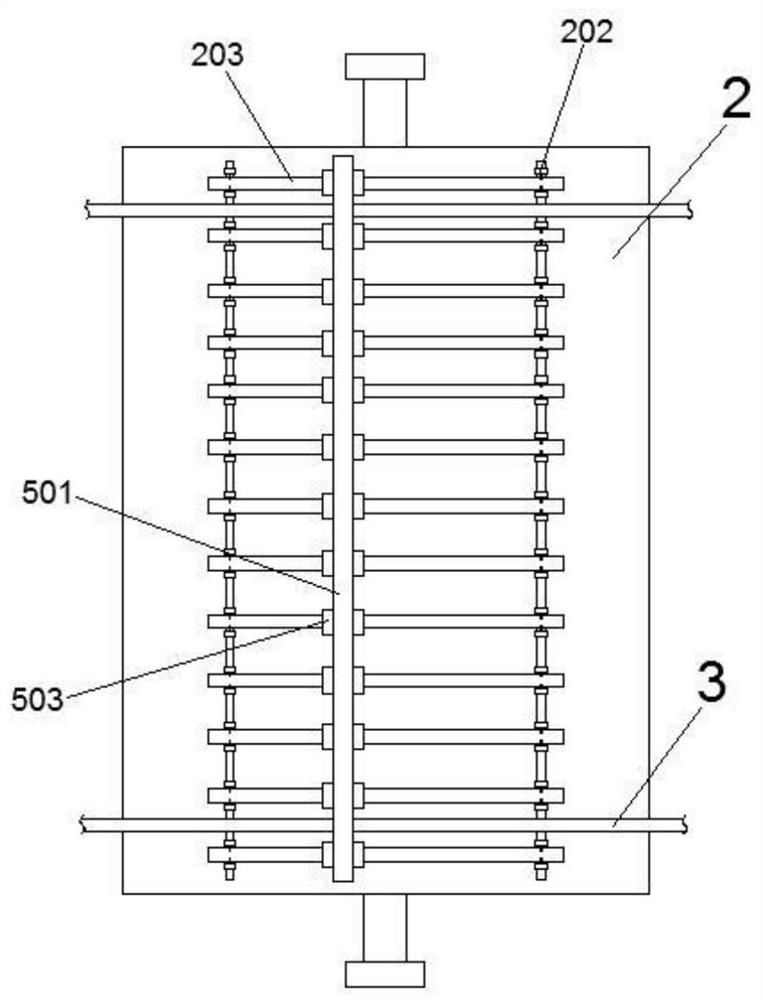

[0048] This embodiment is another optimization scheme made on the basis of embodiment 1, and its main structure is the same as that of embodiment 1, and the improvements are as follows: Figure 6-10 As shown, the two sides of the horizontal reciprocating screw mechanism 3 are respectively rotated and arranged on the lifting slider, and the lifting slider cooperates with the height adjustment screw 4 to realize the adjustment of the height of the horizontal reciprocating screw mechanism 3, and then make it go up The fixed ultrasonic vibration assembly 5 is close to the vitrified tube 203 for descaling or detaching from the rotation track of the reversible carrier 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com