New energy automobile part forging and pressing machining device

A technology for new energy vehicles and processing devices, applied in forging/pressing/hammer devices, forging presses, forging presses, etc., can solve the problems of forging deviation, inconvenience of precise control of included angle, inconvenience, etc., and achieve the effect of reducing deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

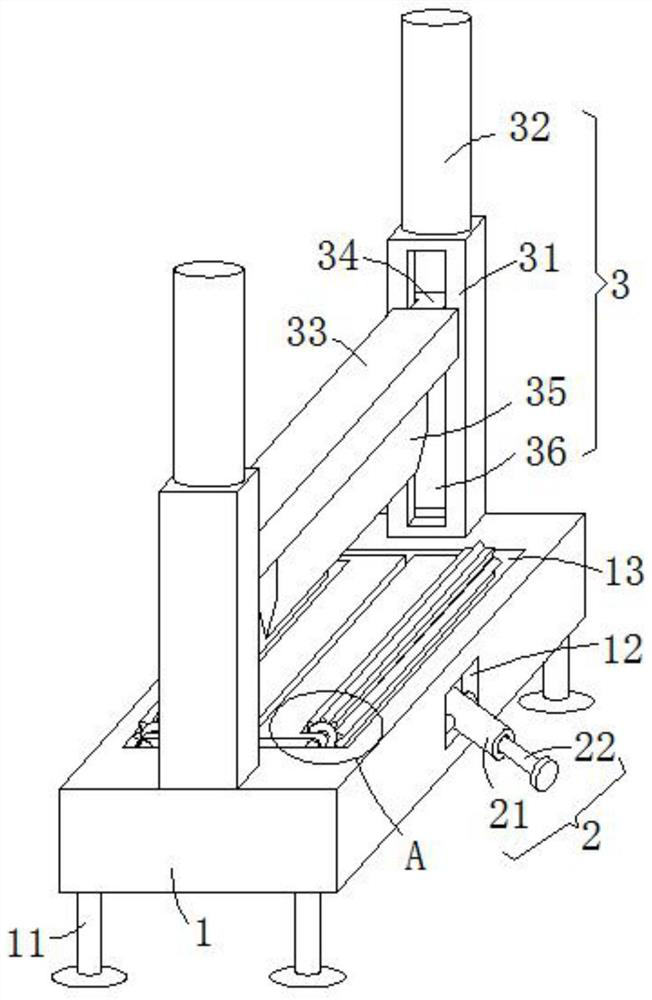

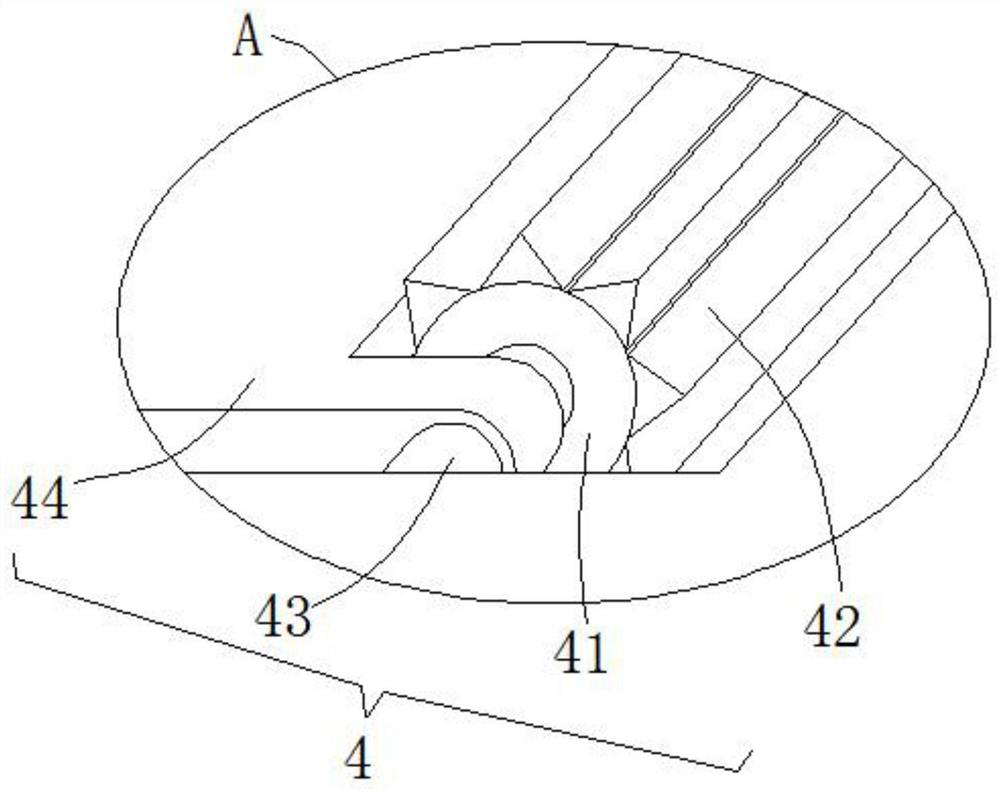

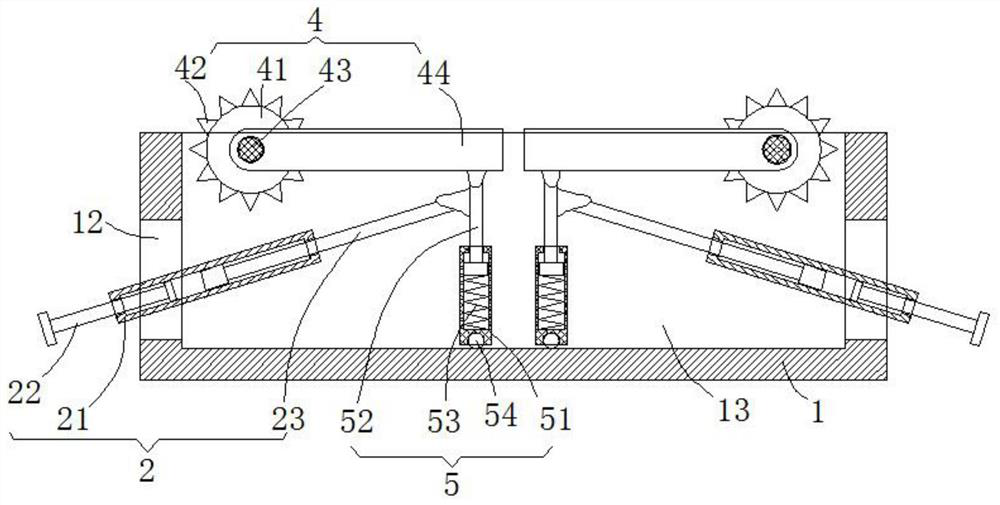

[0021] see Figure 1-3 , this embodiment provides a new energy automobile parts forging processing device, including a processing table 1, the four corners of the bottom surface of the processing table 1 are vertically provided with supporting legs 11, and the processing table 1 is used to place and support Forged auto parts, by setting support legs 11, it is convenient to support the entire processing table 1. The upper end surface of the processing table 1 is provided with a forging mechanism 3. The forging mechanism 3 includes two adjustment support columns 31, two hydraulic cylinders 32 and adjustment The crossbeam 33 and two adjustable support columns 31 are vertically welded on the front and rear sides of the upper end of the processing table 1, and the opposite side walls are provided with T-shaped adjustment grooves 36, and the hydraulic cylinder 32 is vertically arranged on the upper end surface of the adjustment support column 31, and the hydraulic pressure The tip o...

Embodiment 2

[0031] see image 3 , further improvements have been made on the basis of Example 1:

[0032] In order to solve the problem of how to assist the horizontal movement of the entire buffer mechanism 5, the center position of the bottom end of the buffer sleeve 51 is rotated and embedded with a rotating ball 54 that can slide freely on the inner bottom surface of the rectangular buffer groove 13. The end is embedded with a rotating ball 54, so that the rotating ball 54 can slide freely on the bottom end surface of the rectangular buffer groove 13, which is convenient to assist the horizontal movement of the entire buffer mechanism 5 and reduce the sliding friction when the entire buffer mechanism 5 moves horizontally.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com