Machining tool for missile shell and clamping method of machining tool

A shell and missile technology, which is applied in the direction of metal processing equipment, metal processing machinery parts, clamping, etc., can solve the problems that the processing accuracy cannot be guaranteed, and ordinary tooling is difficult to clamp stably, so as to ensure stable clamping and reduce the workpiece Vibration, the effect of improving machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

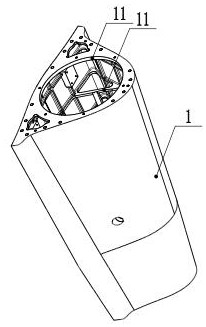

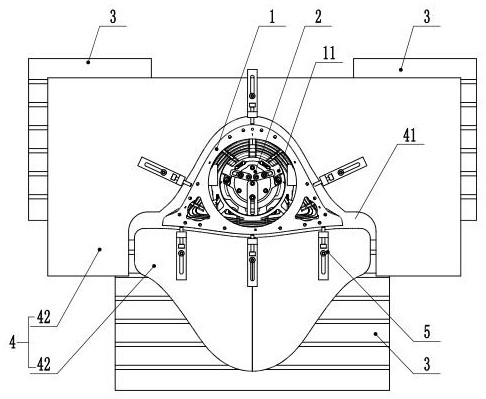

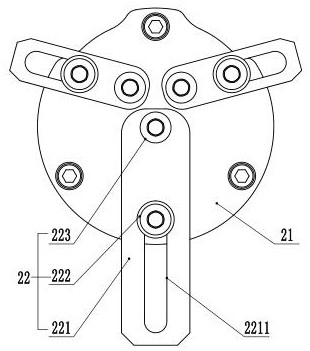

[0043] Such as figure 1 , figure 2and Figure 6 As shown, in this embodiment, a kind of tooling for processing a missile casing includes a pressing mechanism 2 and a top tightening mechanism;

[0044] The pressing mechanism 2 includes a base 21 and a pressing part 22 arranged on the base 21, the base 21 is used to be arranged in the cavity at the bottom of the missile housing 1, and the pressing part 22 is used to press on the Ribs on the inner cavity of the missile casing 1;

[0045] The tightening mechanism includes a supporting component and a tightening component arranged on the supporting component, and the tightening component is used to push the missile casing 1 from the surrounding wall.

[0046] Fix the pressing mechanism 2 and the processing platform, and place the missile housing 1 to be processed on the position of the pressing mechanism 2, so that the pressing mechanism 2 is embedded in the inner cavity of the lower part of the missile housing 1, and adjust th...

Embodiment 2

[0053] Such as Figure 1-Figure 6 As shown, the present invention also discloses a missile shell clamping method, using the above-mentioned missile shell processing tool to clamp the missile shell, the steps are as follows:

[0054] A, the base 21 is installed on the processing platform;

[0055] B, hoisting the missile casing 1 to be processed on the processing platform, so that the base 21 on the processing platform is embedded in the missile casing 1 from the lower end of the missile casing 1;

[0056] C. Operate the pressing part on the base 21 through the operating tool 6, so that the pressing part compresses the rib plate 11 on the inner wall of the missile casing 1;

[0057] D. A tightening mechanism is arranged around the missile casing 1, and the missile casing 1 is tightened from the peripheral wall of the missile casing 1 through the tightening parts in the tightening mechanism.

[0058] Specifically, the operating tool 6 includes a handle 61, and an operating par...

Embodiment 3

[0062] Such as Figure 5 As shown, in this embodiment, the difference from Embodiment 2 is that the operating part 62 includes a magnetic part, and the magnetic part can absorb the pressing plate 221 in the pressing unit 22, so as to rotate and stretch the pressing plate 221 through the handle 61, The pressure plate 221 overlaps the rib plate 11 on the inner wall of the missile casing 1 .

[0063] Further, the magnetic component is an electromagnet, and the electromagnet not only has a strong adsorption capacity, but also has a controllable suction force and is more convenient to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com