High-efficiency multifunctional shoes and production technology thereof

A production process and multi-functional technology, applied in the field of shoes, can solve the problems of lack of support force adjustment function, insufficient adhesion of the sole, and shorten the service life of the sole, so as to increase the comfort and stability of the foot, improve the overall quality, good running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

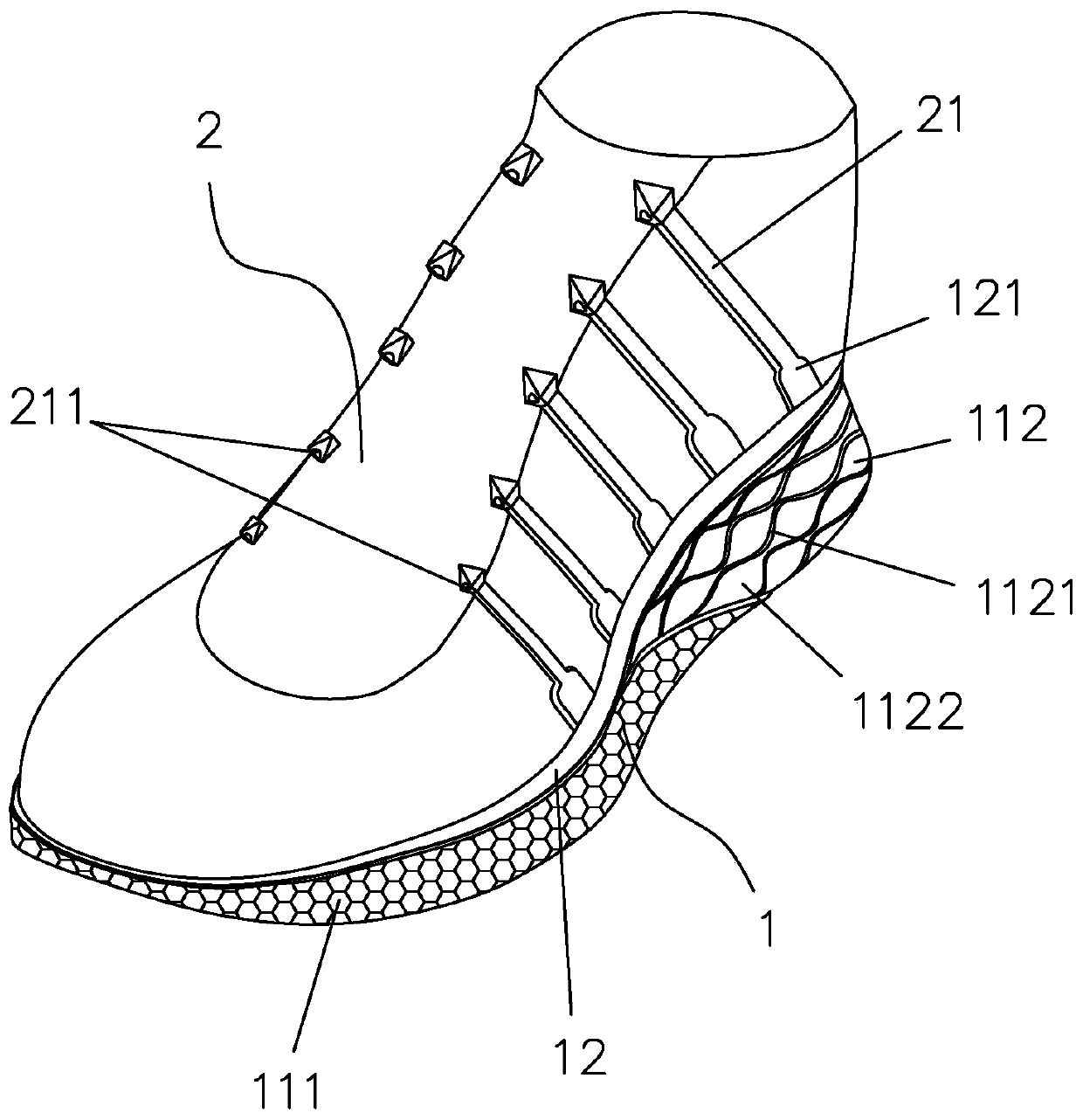

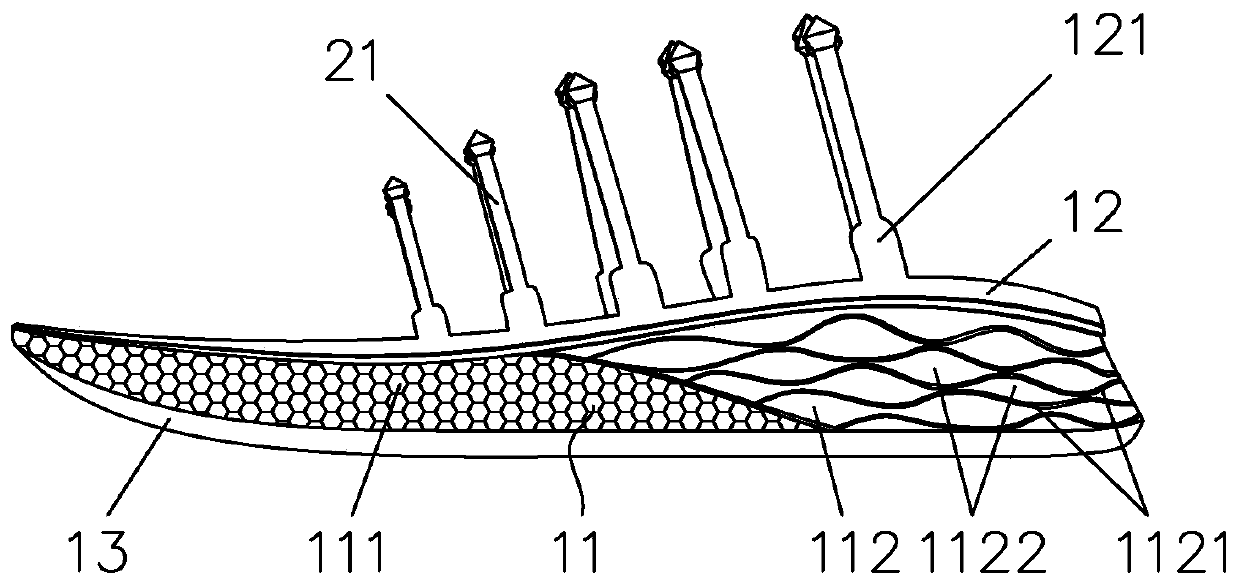

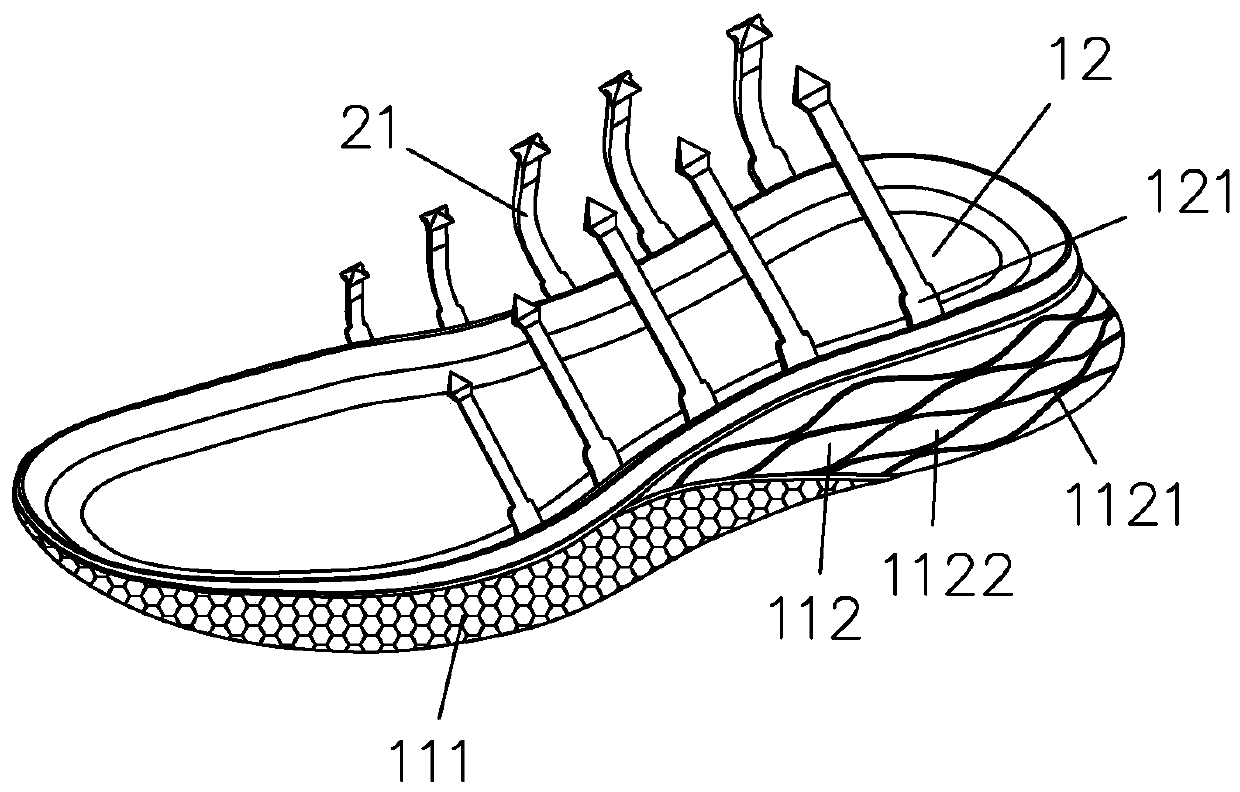

[0034] Such as Figure 1-4 As shown, a high-efficiency multifunctional shoe includes a sole 1 and an upper 2, wherein the sole 1 includes a midsole 11 and a connecting layer 12, the upper 2 includes several tightening claws 21, and the midsole 11 includes an independently formed The forefoot body 111 and the heel body 112, the midsole 11, the connecting layer 12 and the tightening claw 21 are arranged sequentially from bottom to top, and the midsole 11 and the tightening claw 21 are connected as one when the connecting layer is heated and formed.

[0035] Preferably, the forefoot body 111 adopts ETPU material molding, such as steam foam molding, and the heel body 112 adopts EVA material molding, and different materials are used to achieve different performances. After the forefoot body 111 and the heel body 112...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com