Device for assembling thin film check ring of aero-engine thrust augmentation fuel distributor

An aero-engine and afterburner fuel technology, which is used in hand-held tools, manufacturing tools, etc., can solve the problems of difficult to stop the verticality of the ring, engine failure, damage to the casing and sealing ring, etc., to achieve efficient operation and convenience. Manual operation, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

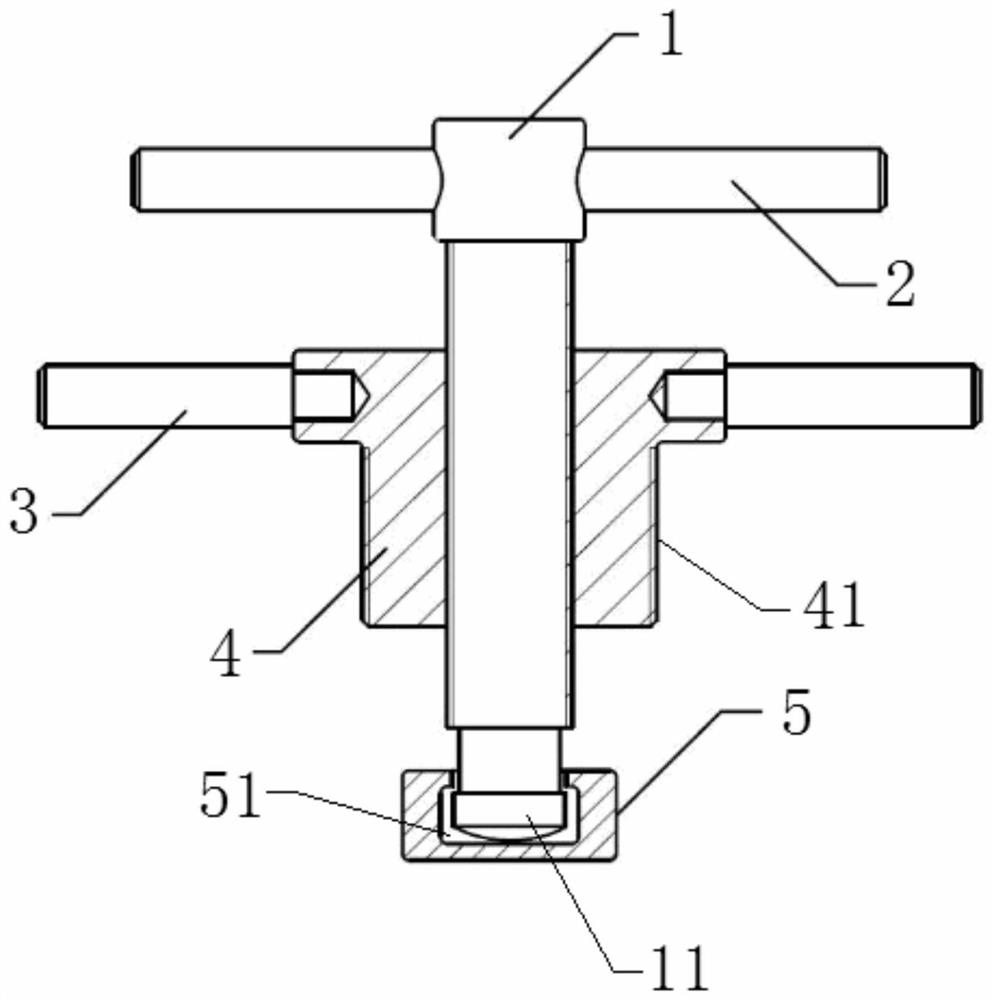

[0023] Such as figure 2 As shown, the present invention includes a pressure rod 1 and a fixed seat 4, the lower end of the pressure rod 1 is provided with a pressure head 11, the lower end of the fixed seat 4 is provided with a positioning boss 41, and the outer circular surface of the positioning boss 41 is provided with a The external thread of the fuel distributor housing; the middle part of the fixing seat 4 is provided with a threaded through hole coaxially arranged with the positioning boss 41, and the threaded through hole is threadedly connected with the shaft of the pressure rod 1. During implementation, the fixed seat 4 is fixedly connected with the casing of the afterburner fuel distributor, and the stop ring is pressed down to provide a reverse force; then the stop ring can be assembled by rotating the pressing rod 1 . The present invention replaces the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com