A production equipment for planning

A production equipment and planning technology, which is applied in the field of planning and processing equipment, can solve the problems of the punching machine being difficult to penetrate, too much paper, etc., and achieve the effects of avoiding energy waste, improving too much paper, and ensuring the punching position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

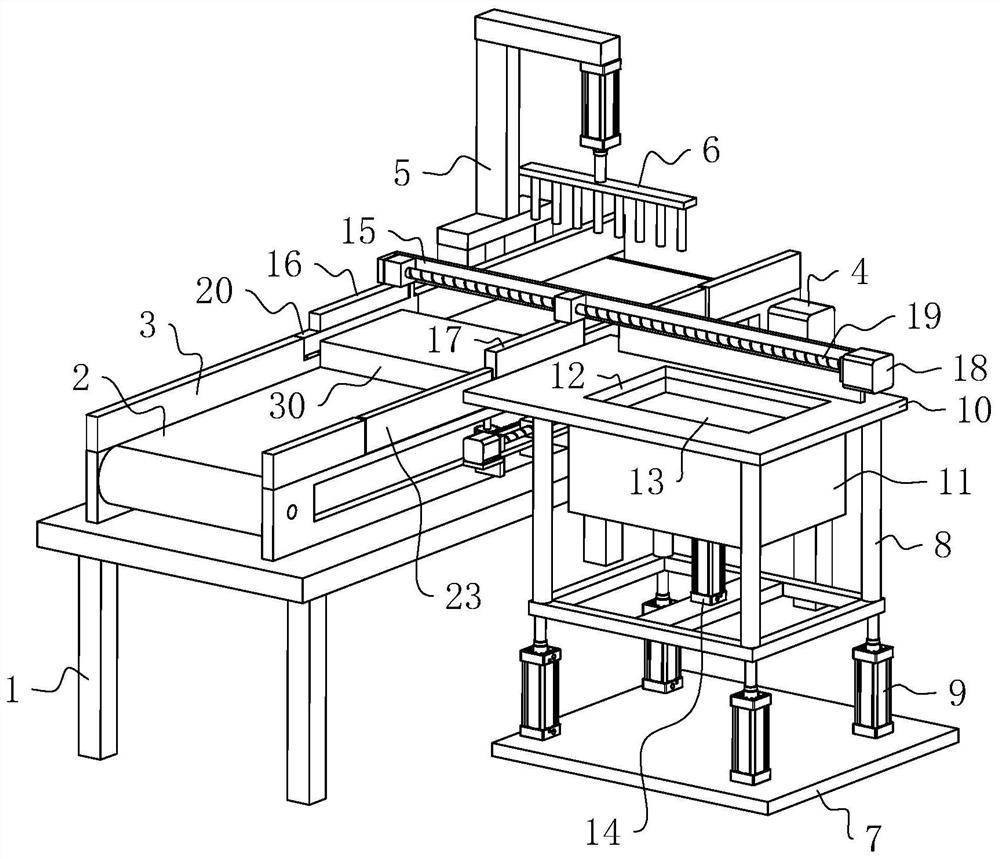

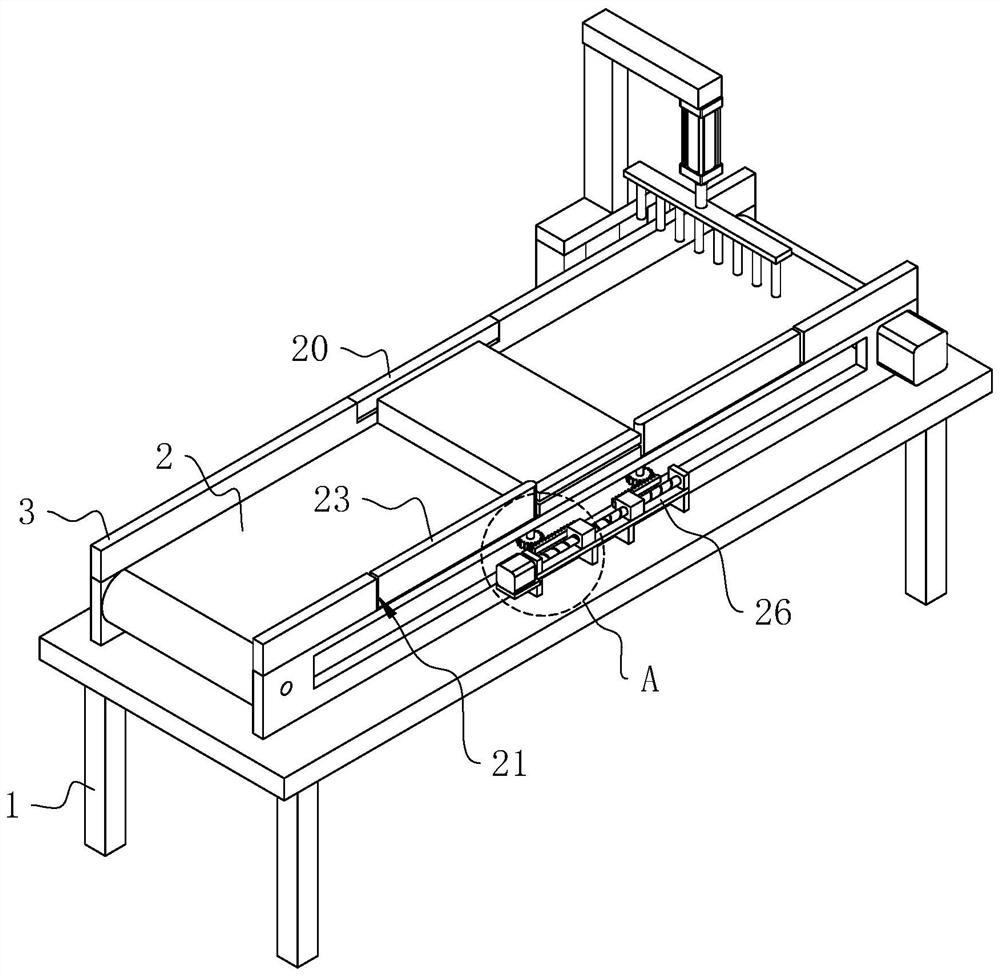

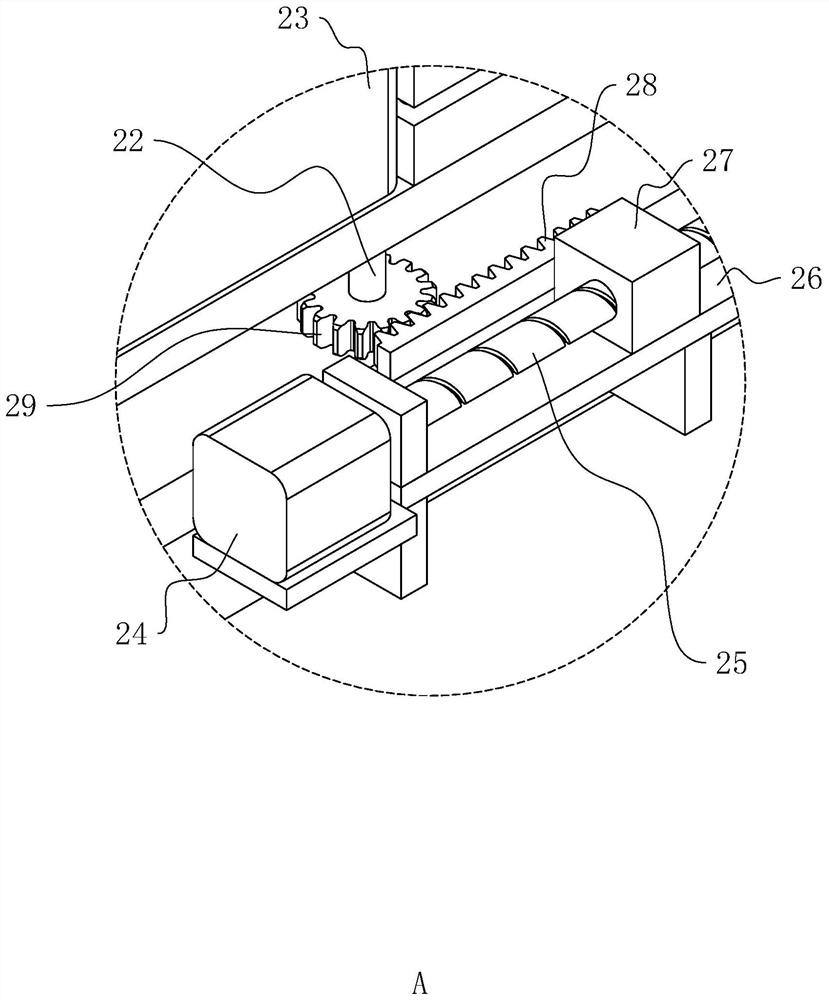

[0031] The following is attached Figure 1-3 The application is described in further detail.

[0032] The embodiment of the present application discloses a planned production equipment. refer to figure 1 and figure 2 , the equipment includes a bracket 1, the bracket 1 is installed with a conveyor belt 2 along its length, the bracket 1 is vertically fixed and connected with baffles 3 on both sides of the length direction of the conveyor belt 2, and one of the baffles 3 is fixedly connected with a motor by screws. 4. Motor one 4 is used to drive the conveyor belt 2 to rotate. Motor one 4 is a servo motor used to control the intermittent start of the conveyor belt 2. The bracket 1 is fixedly connected with the mounting frame 5, and the mounting frame 5 is fixedly connected with the punching machine 6 by screws.

[0033] The equipment also includes a base plate 7 arranged on the side of the support 1, the base plate 7 is fixedly connected on the ground through anchor bolts, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com