Auxiliary braking system based on independent suspension

A technology of auxiliary braking and independent suspension, applied in the field of automobile braking, can solve the problems of brake failure and many reasons for braking, and achieve the effect of improving braking force, reducing risks and improving safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

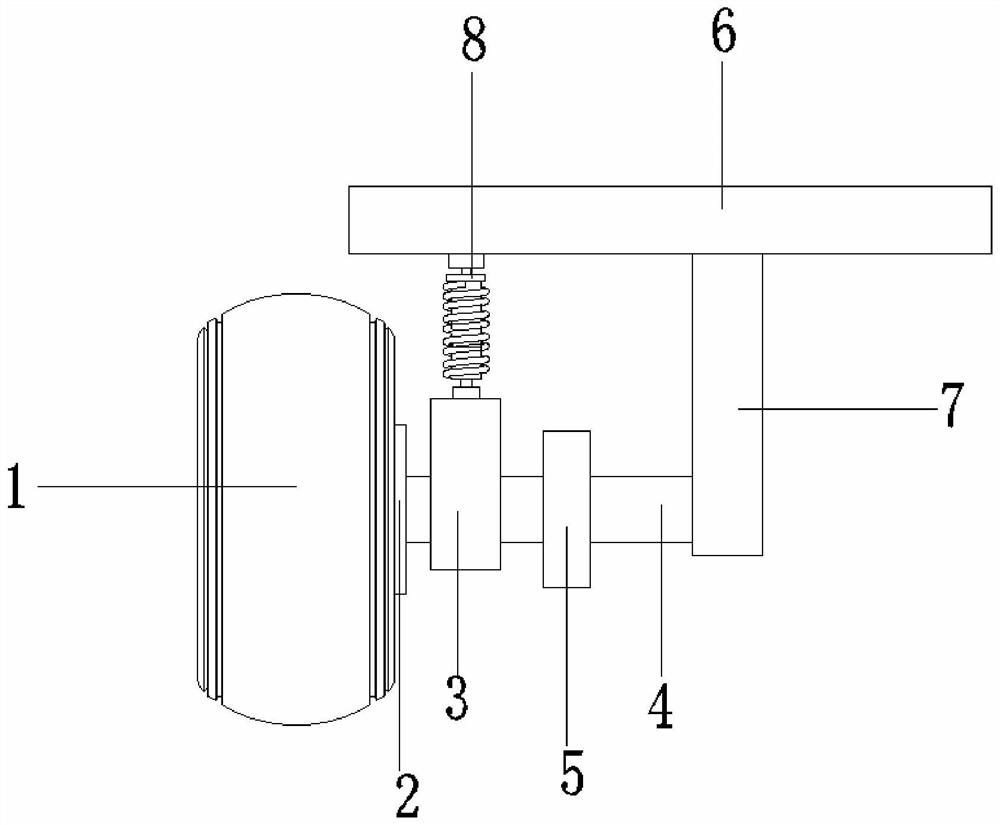

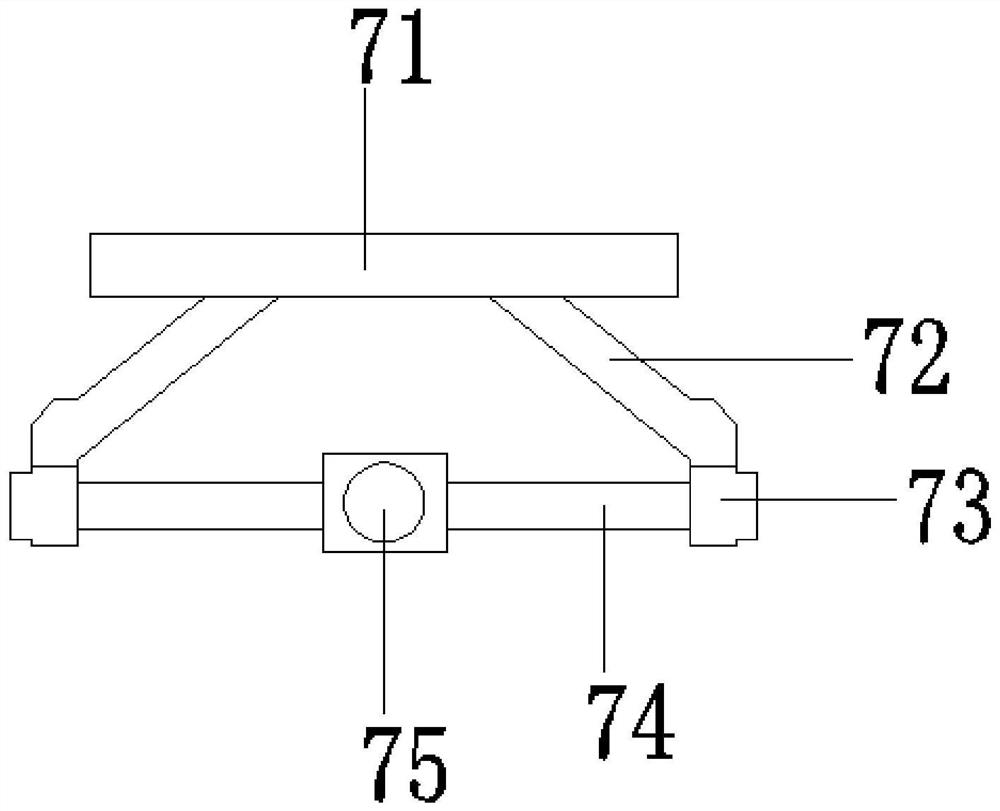

[0028] An auxiliary braking system based on an independent suspension, comprising: a wheel 1 and a vehicle frame 6, the vehicle frame 6 is installed on the chassis position on the driven wheel side of the automobile, the wheel 1 is arranged at the side end of the vehicle frame 6, and a useful In the brake assembly for braking the wheel 1, an inner bearing 2 is provided at the center of the inner end of the wheel 1, and an axle 3 is inserted into the inner bearing 2, and the axle 3 extends toward the middle of the lower end of the frame 6. The axle 3. An auxiliary brake assembly 5 for auxiliary braking of the axle 3 is provided at the middle position, and the auxiliary brake assembly 5 and the brake assembly are driven by the same source;

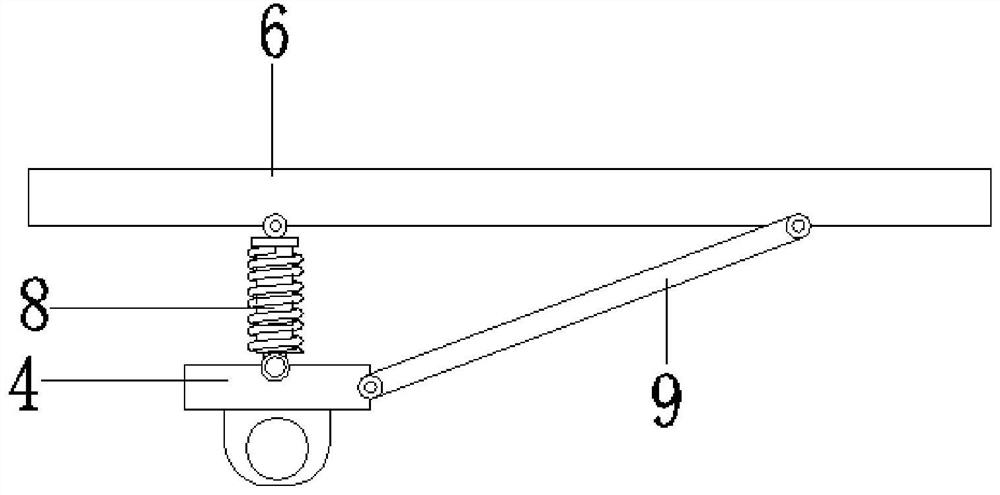

[0029] Also be provided with bearing seat 4 between described auxiliary brake assembly 5 and wheel 1, axle shaft 3 passes through in bearing seat 4, and the upper end of bearing seat 4 is provided with spring shock absorber 8, and the upper e...

Embodiment 2

[0036] An auxiliary braking system based on an independent suspension, comprising: a wheel 1 and a vehicle frame 6, the vehicle frame 6 is installed on the chassis position on the driven wheel side of the automobile, the wheel 1 is arranged at the side end of the vehicle frame 6, and a useful In the brake assembly for braking the wheel 1, an inner bearing 2 is provided at the center of the inner end of the wheel 1, and an axle 3 is inserted into the inner bearing 2, and the axle 3 extends toward the middle of the lower end of the frame 6. The axle 3. An auxiliary brake assembly 5 for auxiliary braking of the axle 3 is provided at the middle position, and the auxiliary brake assembly 5 and the brake assembly are driven by the same source;

[0037] Also be provided with bearing seat 4 between described auxiliary brake assembly 5 and wheel 1, axle shaft 3 passes through in bearing seat 4, and the upper end of bearing seat 4 is provided with spring shock absorber 8, and the upper e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com