Mining ultrahigh-extension prestressed steel strand and manufacturing method thereof

A technology of prestressed steel strands and manufacturing methods, which is applied in the direction of textiles, papermaking, and textile cables, and can solve problems such as hidden dangers in mine safety production and operation, strong mine pressure, and increased mine depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

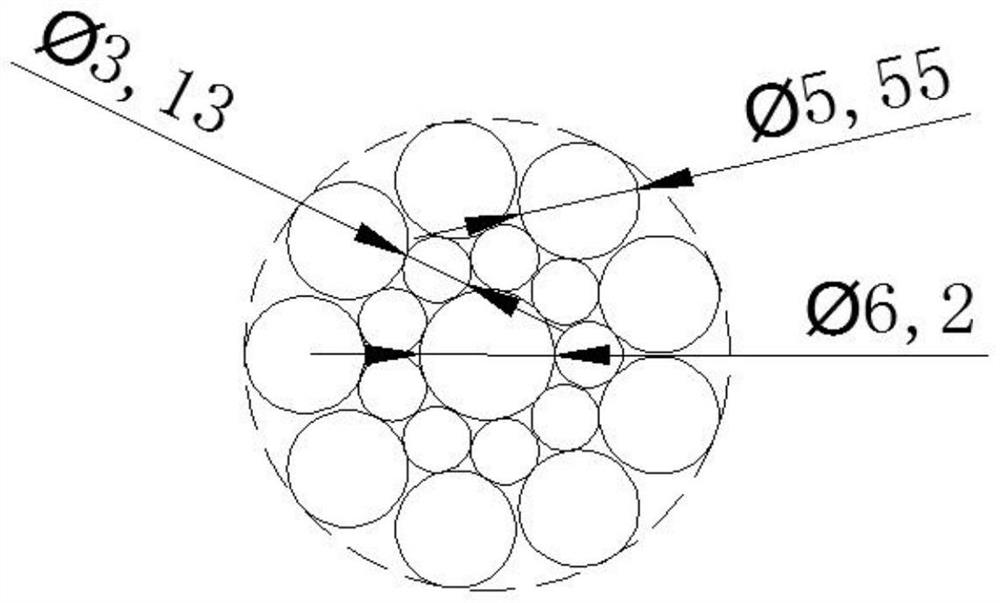

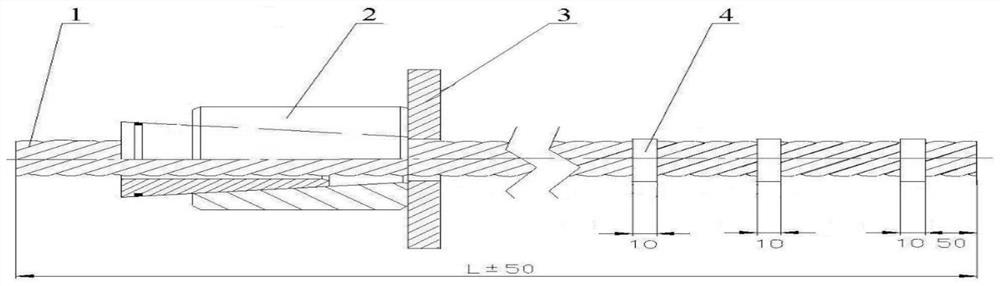

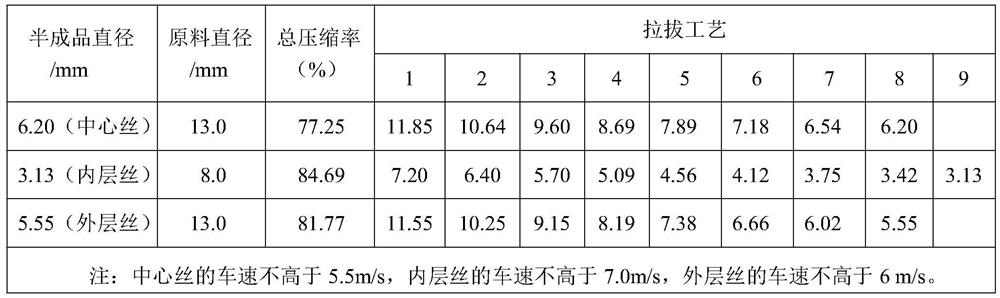

[0024] Mining ultra-high elongation prestressed steel strands, including a central wire, nine inner wires and nine outer wires, the central wire, inner wires and outer wires adopt a Xilu structure, the same layer, And the steel wires between the layers are closely attached one by one and contact each other in a linear manner. The innovation of the present invention is that the nominal diameter of the central wire is 6.1-6.3mm, and the nominal diameter of the inner layer wire is 3.10-3.15 mm. mm, the nominal diameter of the outer layer wire is 5.5-5.6mm, and the nominal diameter after twisting is 21.8mm. Among the process parameters of the steel strand, the tensile strength is ≥ 1860MPa, and the elongation is ≥ 7.0%. The optimized wire distr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Nominal diameter | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

| Nominal diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com