Drainage well for sunken pit bottom of inner dumping site and drainage method of drainage well

A technology of internal soil drainage and dredging wells, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of poor drainage effect, long construction period, and large investment, so as to facilitate drainage, reduce investment costs, and shorten construction projects. The effect of duration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

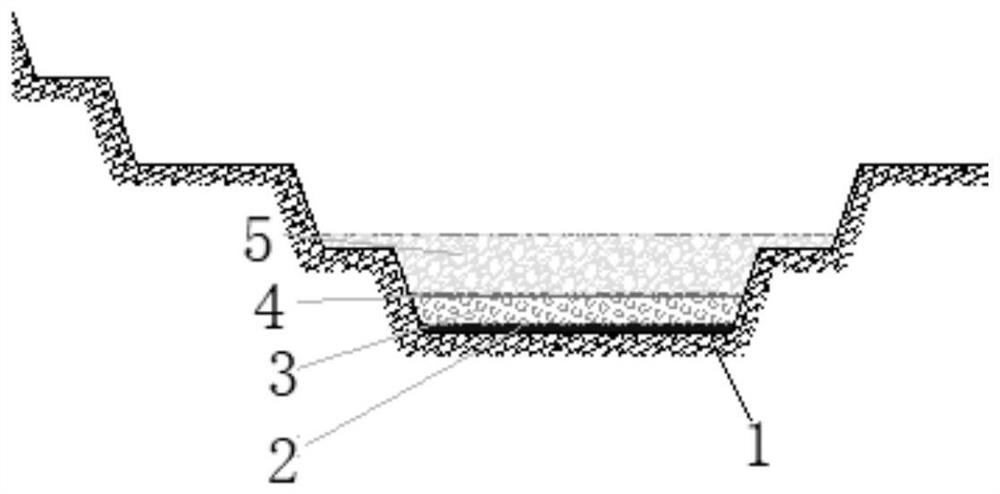

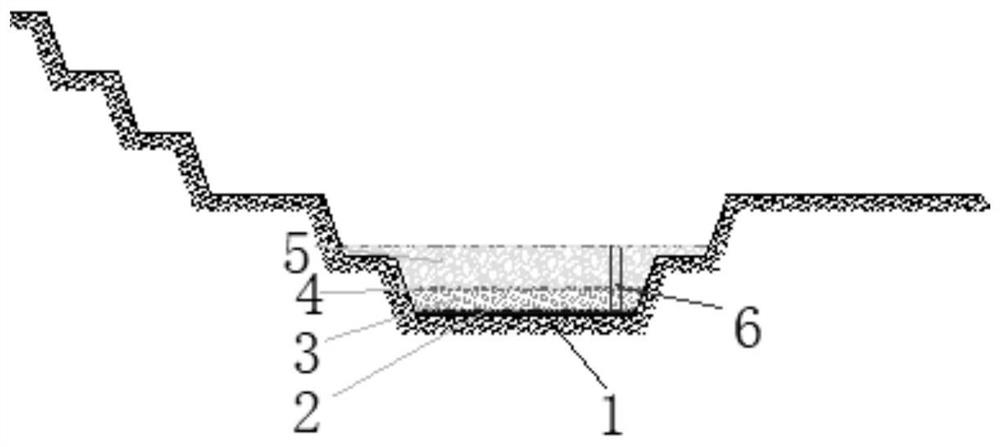

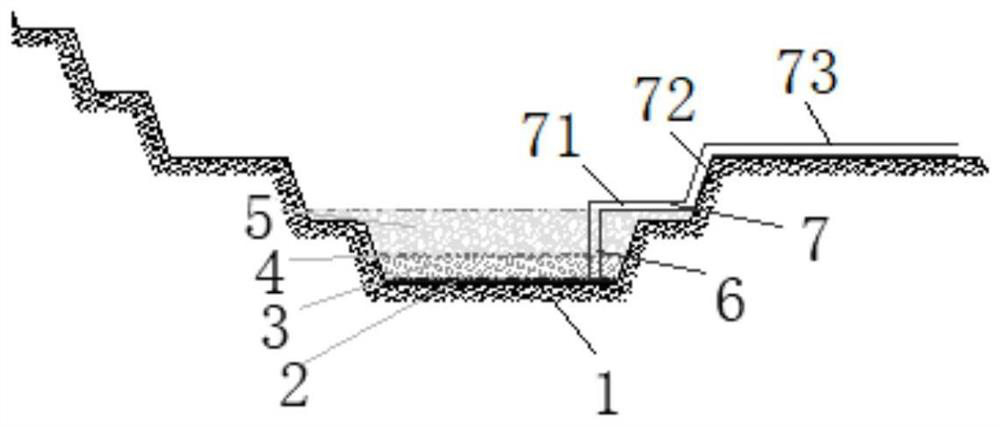

[0037] A kind of dredging well and its dredging method at the bottom of the depression pit of the inner dump site of this embodiment, such as Figure 1 to Figure 4 As shown, the bottom of the pit 1 includes a backfill layer 2, a large filter layer 3, a permeable geotextile 4 and a waste rock layer 5 arranged sequentially from bottom to top; Well 6, the water outlet of the draining well 6 is located outside the waste rock layer 5; it also includes a drain pipe 7, the water inlet end of the drain pipe 7 is connected with the water outlet of the draining well 6, and the water outlet extends Beyond the slope of the dump site.

[0038] Such as figure 1 As shown, the backfill layer 2 is provided with multiple layers, and each layer has a thickness of 0.5 to 1.0 meters. Each layer is tiled at the bottom of the pit 1 to form a water catchment area. Large block water filter layer 3, the thickness of the large block water filter layer 3 is not less than 0.5 meters, forming an artifici...

Embodiment 2

[0047] A kind of dredging well and its dredging method at the bottom of the inner dump pit of the present embodiment, the basic structure is the same as that of embodiment 1, the differences and improvements are as follows: Figure 1 to Figure 4 As shown, the method for drying at the bottom of the pit 1 of the inner dump site includes the following steps:

[0048] Step 1, treating the bottom of the pit: laying a backfill layer 2, a large filter layer 3, a permeable geotextile 4 and a waste rock layer 5 on the bottom of the pit 1 from bottom to top;

[0049] Step 2, arranging drainage wells: a drainage well 6 is vertically arranged at the backfill layer 2, and the drainage well 6 includes a well wall pipe, a filter pipe and a sedimentation pipe connected in sequence, and the outlet of the sedimentation pipe extends out of the waste water. Outside the stone layer 5; and a deep water pump is arranged in the well to pump out the accumulated water;

[0050] Step 3, arranging the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com