A prefabricated sample house for outdoor scientific research

A prefabricated and scientific research technology, applied in protective buildings/shelters, walls, buildings, etc., can solve the problems of easy damage of houses, achieve the effect of resisting strong wind, reducing the probability of disintegration, and passing the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

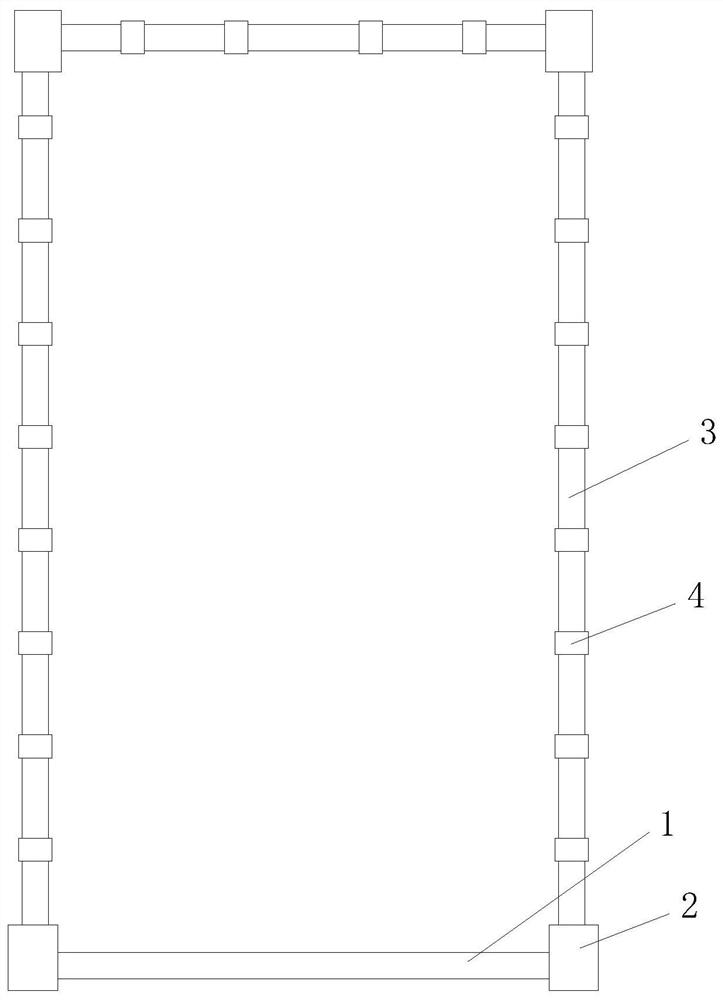

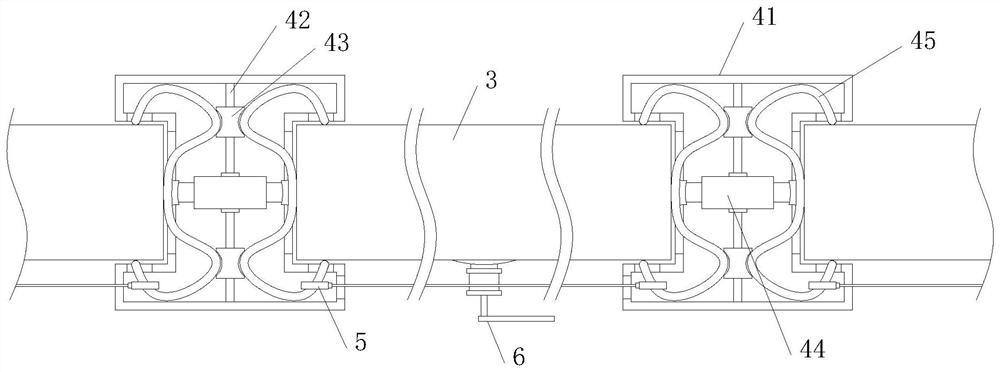

[0024] like Figure 1-2 As shown, the present invention provides a prefabricated sample house for outdoor scientific research, comprising a door body 1, and wall panels 3 are fixedly connected to opposite sides of the door body 1 through corner connecting edges 2, and the wall panels 3 have The two adjacent wall panels 3 are connected by a connector 4. The connector 4 includes an aluminum alloy casing 41. A fixing frame 42 is fixed at the inner middle of the aluminum alloy casing 41. The fixing frame 42 is provided with two Block 43, a responder 44 is fixedly installed on the fixing frame 42 between the abutting blocks 43, both ends of the responder 44 are connected with elastic claws 45, and one end of the elastic claw 45 is hung on the manual winch 6 through the hook 5, The manual winch 6 is fixed on the outer side of the wall panel 3 .

[0025] In this embodiment, by designing a plurality of wall panels 3, the overall shape of the present invention can be adjusted freely, ...

Embodiment 2

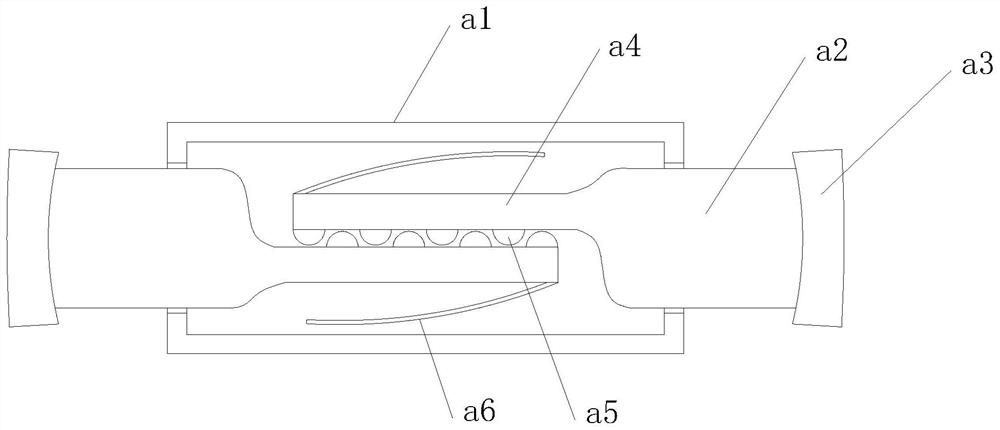

[0027] like Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the responder 44 includes a housing a1, the middle of the housing a1 and the fixing frame 42 are fixedly welded, and both ports of the housing a1 are The piston is connected with a connecting rod a2, an inner rod a4 is provided on one end of the connecting rod a2 inside the casing a1, and a plurality of convex points a5 are provided on one side of the two inner rods a4 that are close to each other, and two sets of convex points a5 are provided. They are arranged in a staggered manner. The side end of the inner rod a4 away from the convex point a5 is provided with a clicker a6. The clicker a6 is an arc-shaped elastic sheet, and the thickness of its fixed end is twice the thickness of the tail end. The elastic claw 45 includes a steel sheet b1. The middle of the steel sheet b1 is fixedly connected with the welding block a3, the two ends of the steel sheet b1 are p...

Embodiment 3

[0030] like Figure 2-3 As shown, on the basis of Embodiments 1 and 2, the present invention provides a technical solution: the cross section of the hook b3 is C-shaped, the curved edge extends toward the bending segment b2, and the outer surface of the hook b3 is There are inverted teeth facing opposite to it.

[0031] In this embodiment, when the steel sheet b1 is squeezed, and the hook b3 is protruded and pressed on the side of the wall panel 3 through the lever principle, the contact between the C-shaped hook b3 and the wall panel 3 The surface is larger, and under the thrust of the steel sheet b1, it tends to move towards the edge of the wall panel 3. The inverted teeth on the outer side are used to increase the friction strength between the two, so that the hook b3 can drive the wall panel 3 to travel. , thereby increasing the connection strength between the connector 4 as a whole and the wall panel 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com