Piston cooling nozzle arrangement system and engine of an engine

A piston cooling nozzle and engine technology, which is applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of complex structure, high cost, multiple oil passages, etc., to solve oil passage leakage, reduce filling volume, The effect of reducing the number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

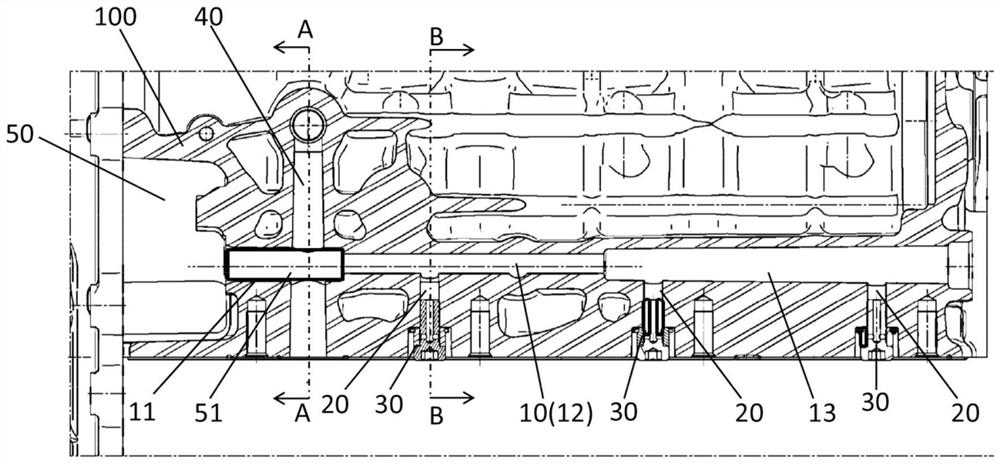

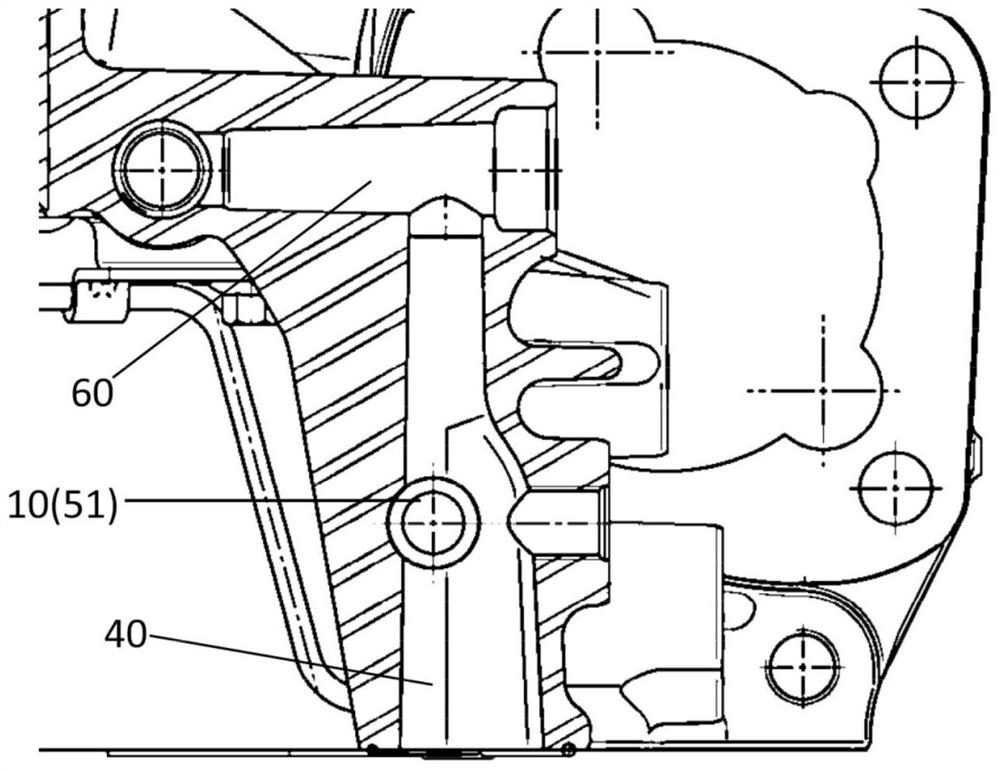

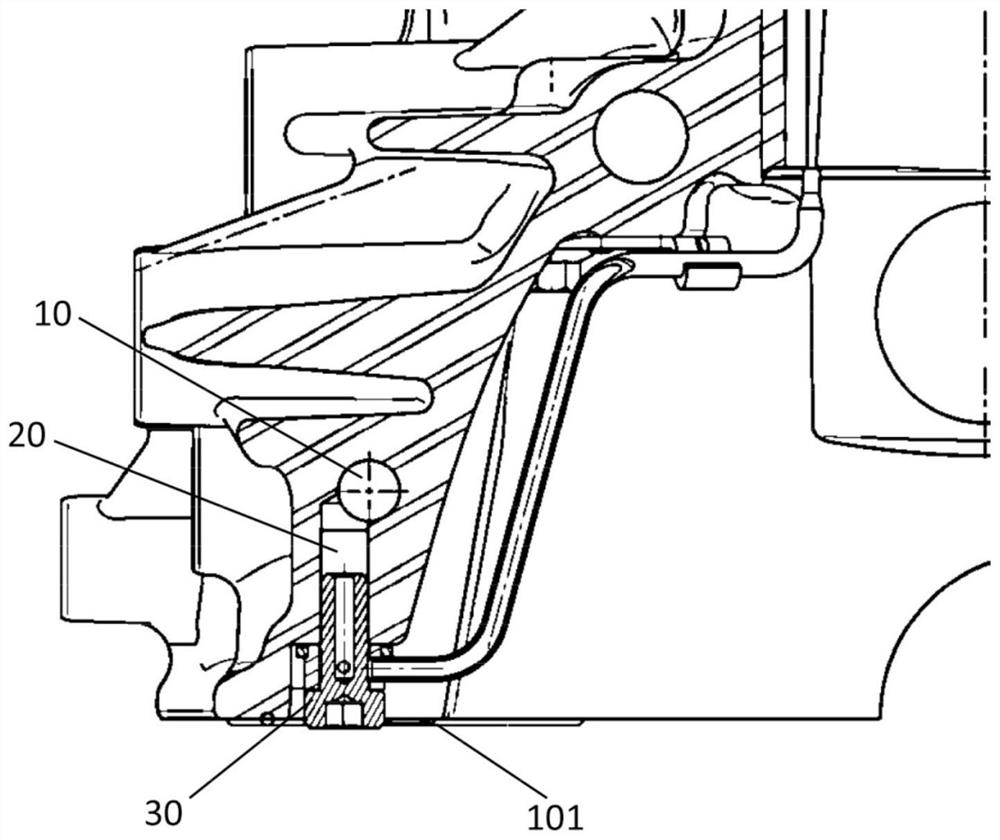

[0030] figure 1 is a cross-sectional view of a piston cooling nozzle arrangement system according to one embodiment of the present invention. figure 2 yes figure 1 Sectional view at A-A in the middle. Such as figure 1 As shown, the present invention provides a piston cooling nozzle arrangement system of the engine, which is arranged on the intake side of the upper cylinder block 100 of the engine oil passage 40, and the piston cooling nozzle arrangement system may generally include transverse oil passages 10, Engine oil passage 40, sub oil passage 20, piston cooling nozzle 30 and electric control valve 50. The transverse oil passage 10 is arranged along the transverse direction of the upper cylinder block 100 , and its lower end is provided with a plurality of sub-oil passages 20 communicating with the transverse oil passage 10 for installing piston cooling nozzles 30 . Engine oil oil channel 40 is connected with horizontal oil channel 10, is used for leading into engine ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com