Automatic drainage system

A water-repelling and automatic technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of low steam utilization rate, waste of steam, and long heating time, so as to improve steam utilization rate and shorten heating time. The effect of controlling time and preventing a large amount of steam loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

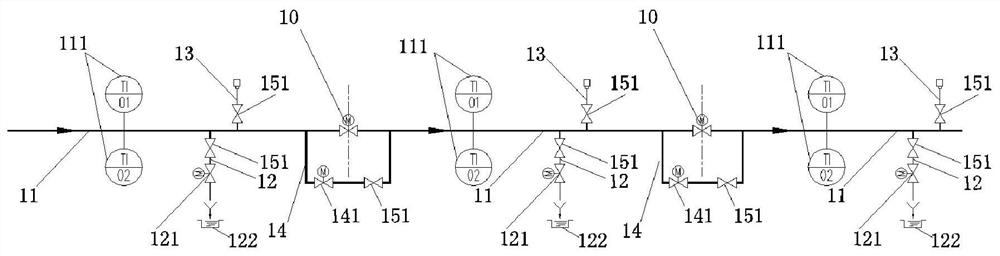

[0032] The technical solutions of the embodiments of the present invention will be described below with reference to the drawings in the embodiments of the present invention.

[0033] In order to improve steam utilization rate and shorten pipe warming time, an embodiment of the present invention provides an automatic drainage system.

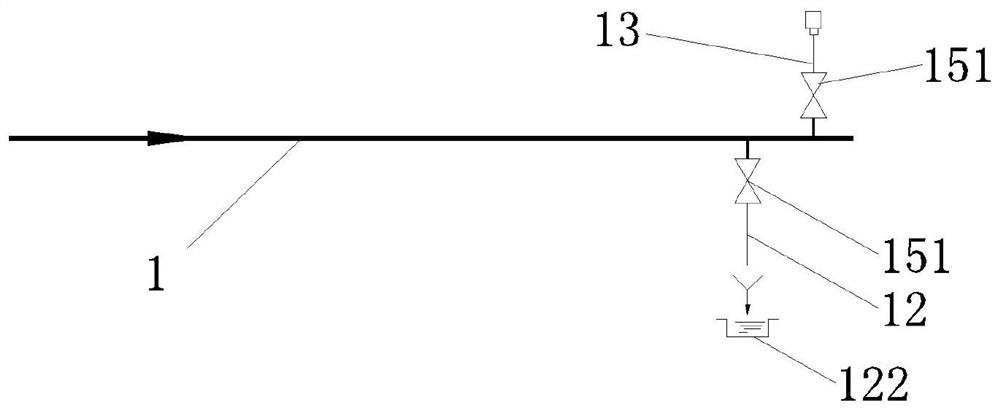

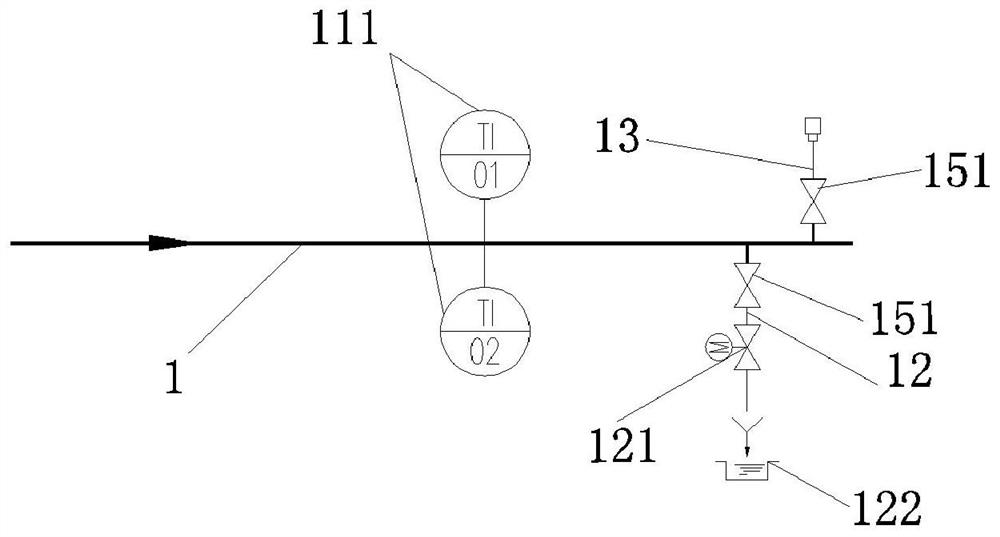

[0034] Such as figure 2 As shown, a kind of automatic hydrophobic system that the embodiment of the present invention provides, comprises:

[0035] The temperature detection component 111 is arranged on the steam pipeline 1, and is used to measure the temperature of the top inner wall and the bottom inner wall of the steam pipeline 1;

[0036] A flow regulating device 121, arranged on the drain pipe 12 of the steam pipe 1, for adjusting the outlet flow of the drain pipe 12;

[0037] The control device is used to adjust the outlet flow of the drain pipe 12 by controlling the flow regulating device 121 according to the temperature of the top in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com