Particle combustion furnace

A combustion furnace and particle technology, applied in the direction of combustion methods, combustion equipment, solid fuel combustion, etc., can solve the problems of insufficient combustion of particle fuel, inability to support combustion, and poor user experience, so as to improve the efficiency and effect of ash falling, Improved fuel efficiency and good combustion-supporting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

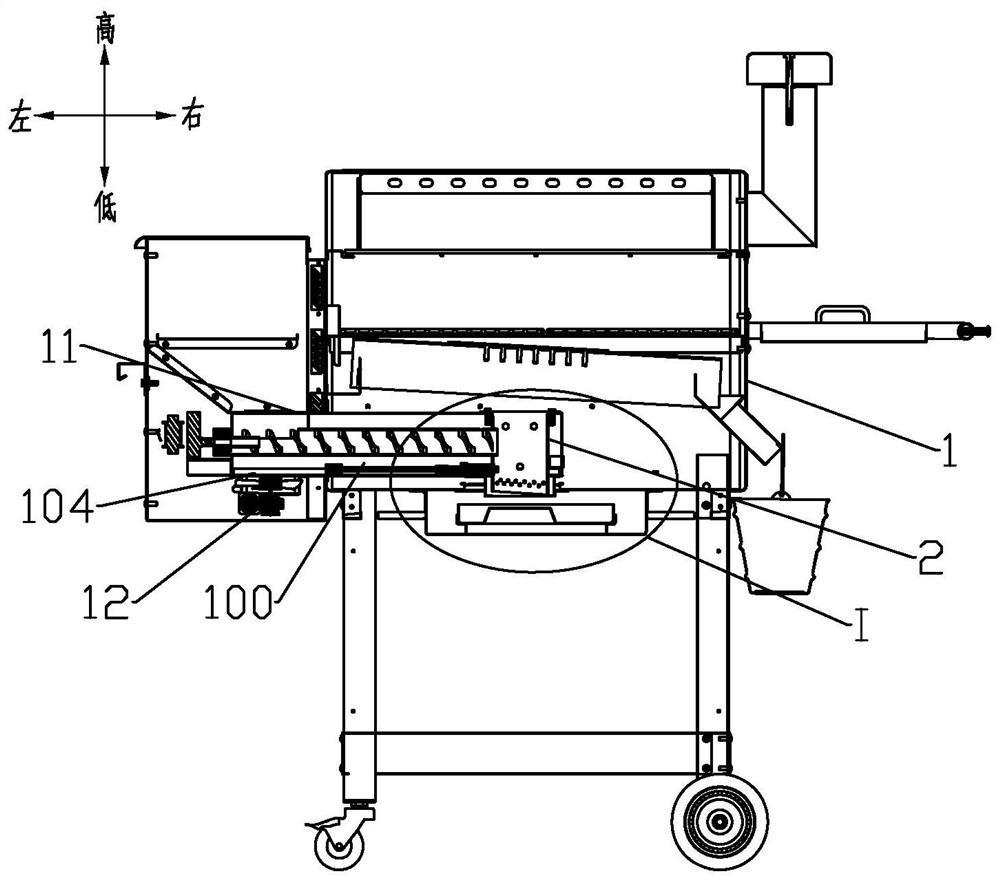

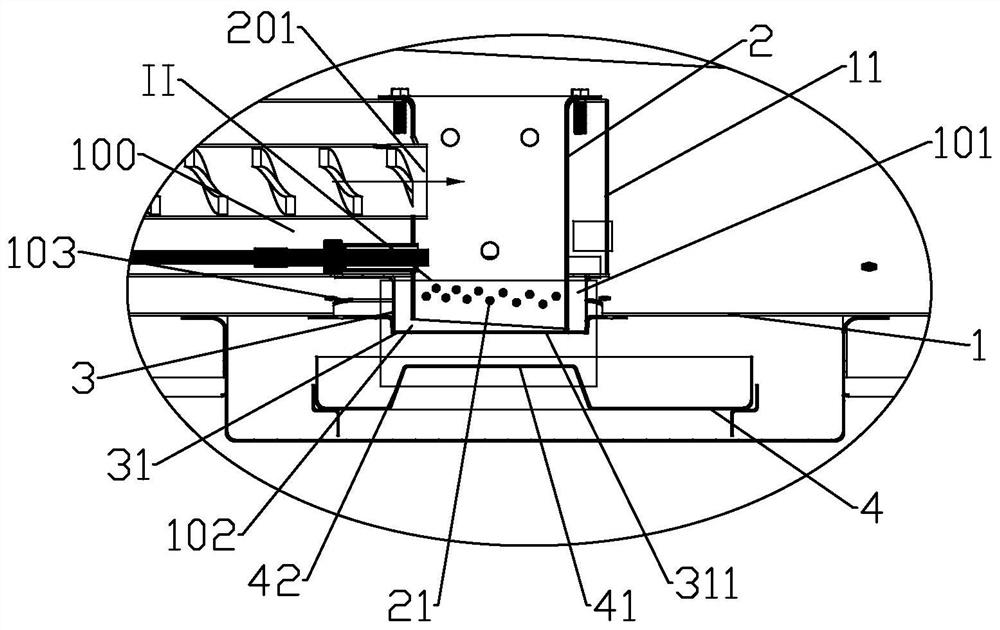

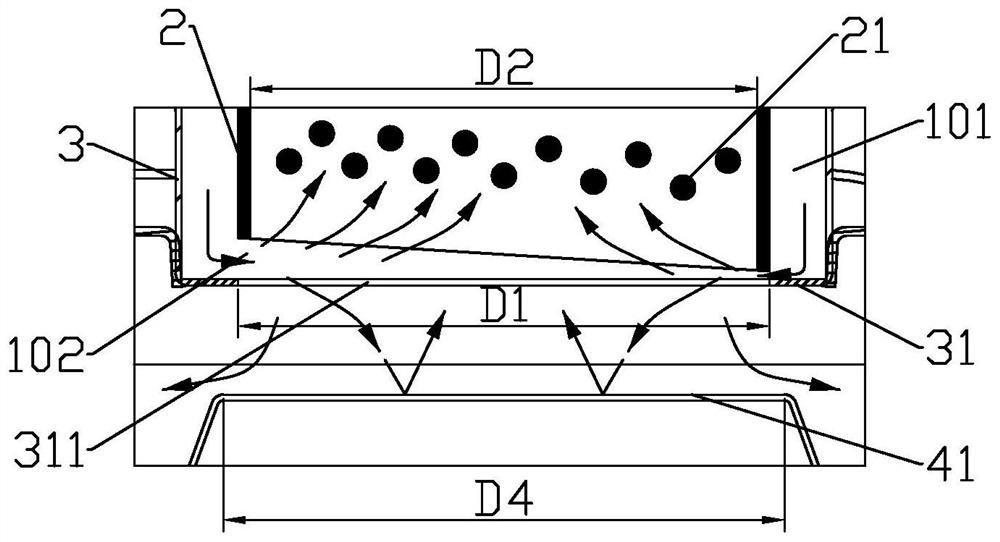

[0022] Such as Figure 1 to Figure 4 As shown, the present invention provides a particle combustion furnace, comprising a furnace body 1, a burner 2 is provided in the furnace body 1, and the furnace body 1 is provided with an air supply channel 100 for feeding air from the outside of the furnace body 1, and the burner 2 The bottom surface is provided with a through-hole for air intake and ash fall, and a fire grate 21 is arranged above the through-hole. The outer wall of the bottom of the burner 2 is provided with an air guide channel 101. The bottom end of the wind channel 101 is provided with an annular windshield 31, and there is an annular air intake gap 102 between the annular windshield 31 and the bottom end of the burner 2. The inner ring of the annular windshield 31 forms a through hole 311, and the bottom of the annular windshield 31 is provided with The rebounding windshield 41 , the rebounding windshield 41 passes through the through hole 311 and faces the through ...

Embodiment 2

[0031] Such as Figure 5 As shown, the inner bottom surface of the ash tray 4 can be directly designed to form a rebound windshield 41.

[0032] For other content not described in this embodiment, reference may be made to the foregoing embodiments.

Embodiment 3

[0034]In addition to setting the ash tray, a water storage tray can also be provided at the bottom of the furnace body. The water storage tray is provided with an upwardly protruding boss, and the top surface of the boss forms a rebound windshield; or, directly use the water surface in the water storage tray Form a rebound windshield. The water storage tray is used to collect the ash, because the pellet fuel burns in the burner, it will generate more heat, the water in the water storage tray is heated, and the evaporation and vaporization of the water are accelerated, and the ash after the pellet fuel burns falls through the through hole. In the process of entering the water storage tray, it will combine with water vapor, which will increase the weight of the ashes and make it easier to fall into the water storage tray without being blown up and flying in the furnace body, which can play a self-cleaning role; water vapor can Combining with the carbon molecules produced during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com