Design method of spiral wounded heat exchanger with shell side boiling and tube side condensation

A winding tube and design method technology, applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of design level and manufacturing capacity not reaching the core competitiveness, complex process calculation, etc., and achieve high commercial value and market The effect of promoting value, high calculation efficiency, and complete design method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

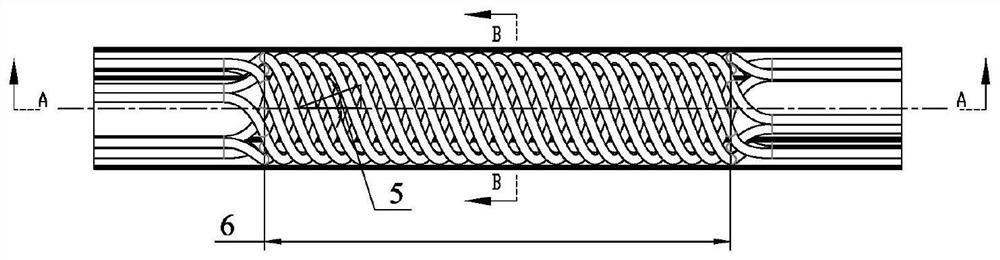

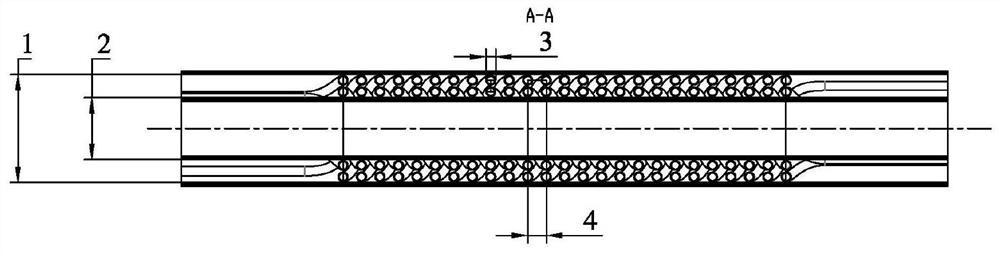

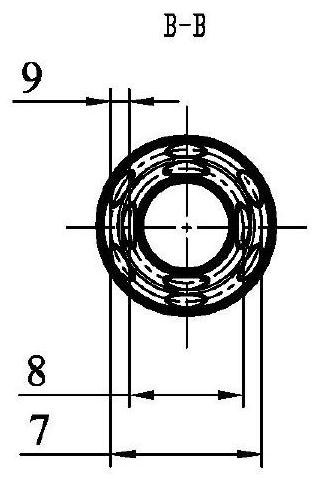

[0081] Embodiment 1, with reference to Figure 1-8 , a design method of a coiled tube heat exchanger with shell-side boiling and tube-side condensation, according to the structural characteristics of the coiled tube, there are certain geometric constraints on the coiled tube and its tube bundle, and the design method is based on this geometric constraint , provides the coiled tube layout method of the coiled tube heat exchanger, selects the coiled tubes of the same specification, the winding angle ε of different layers of coiled tubes is the same, and the radial layer spacing H T The same, the axial tube spacing H of different layers of winding tubes L,m The same, the winding diameter of each layer of winding pipe in the winding pipe bundle follows the arithmetic sequence; the winding diameter D co,m , layer gap B T , the number of layers m and the outer diameter of the core tube D C The geometric constraint relationship of is shown in formula (1); , the radial layer spacin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com