Building blasting pre-dust-fall wall surface spraying equipment

A pre-drop and construction technology, applied in blasting, construction, building maintenance, etc., can solve problems such as narrow spraying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

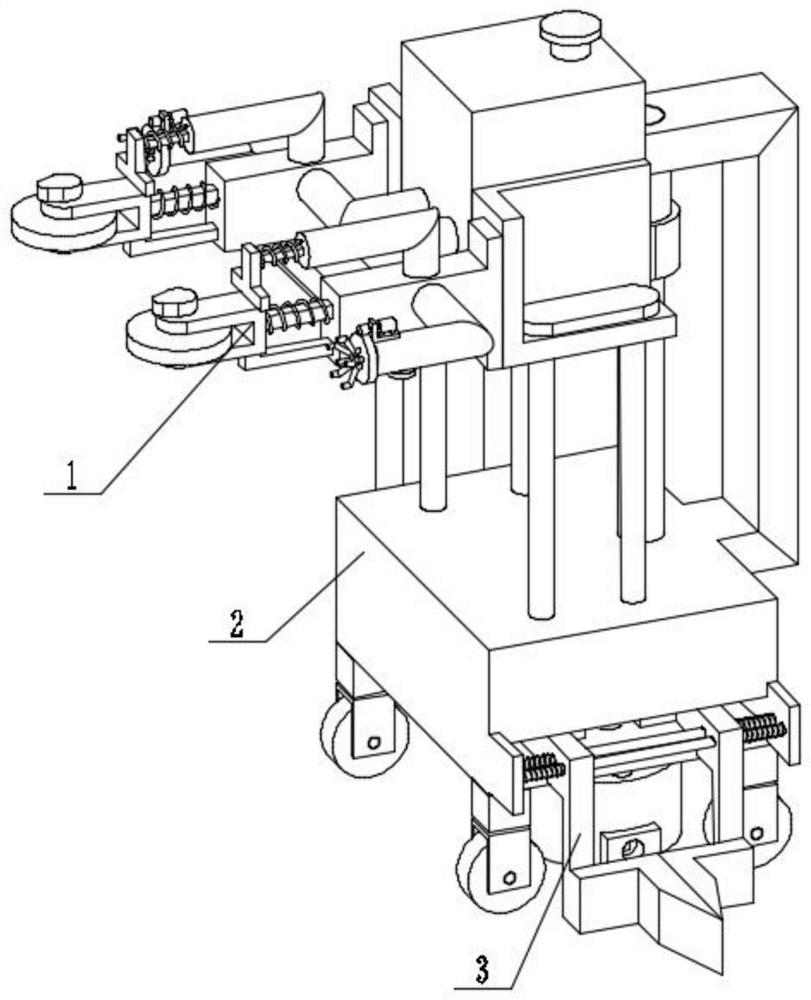

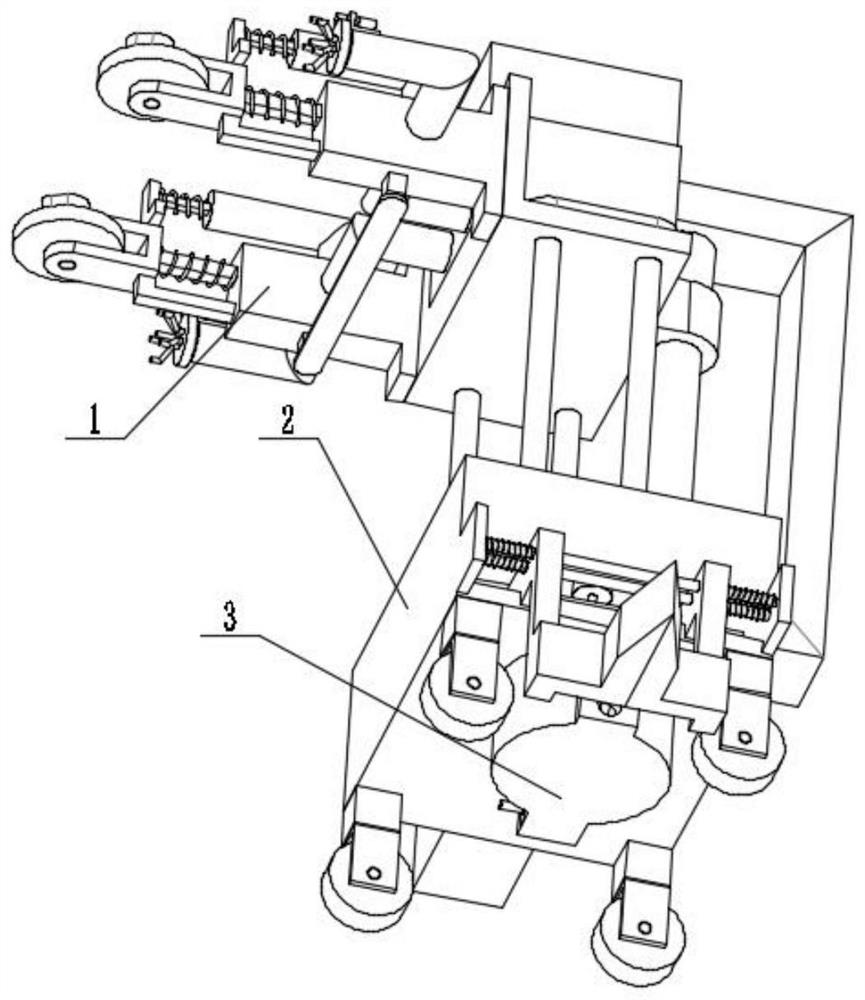

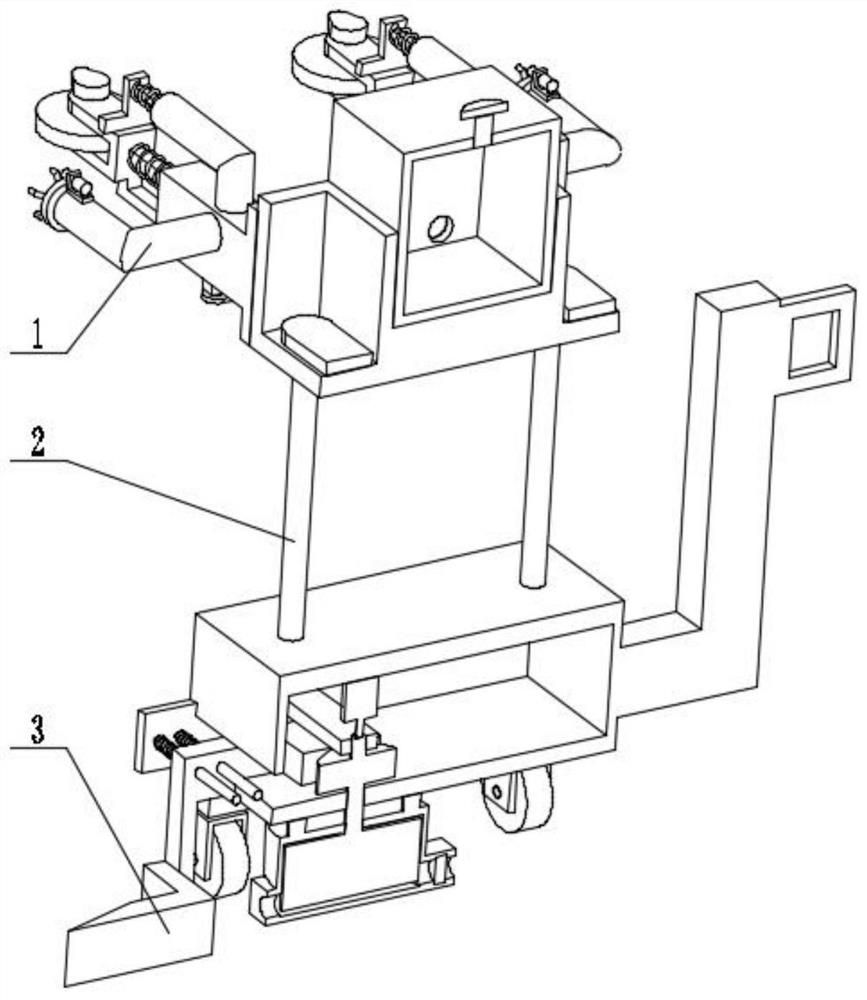

[0032] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16Describe this embodiment, the present invention relates to a kind of spraying equipment, more specifically a kind of construction blasting pre-dedusting wall spraying equipment, including water spraying mechanism 1, vehicle frame mechanism 2, clearing mechanism 3, the equipment can be switched to spraying In the water state, the equipment can use the power of walking to spray water, the equipment can adjust the height of water spray, and the equipment can clear the obstacles in the process of traveling.

[0033] The water spray mechanism 1 is connected to the vehicle frame mechanism 2, and the vehicle frame mechanism 2 is connected to the block clearing mechanism 3.

specific Embodiment approach 2

[0035] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 Describe this embodiment, this embodiment will further explain embodiment 1, described water spray mechanism 1 comprises water spray seat 1-1, spray pipe 1-2, motor 1-3, gear 1-4, belt ring gear Rotating nozzle 1-5, oblique spray pipe 1-6, straight spray pipe 1-7, sliding seat 1-8, pulley seat 1-9, pulley with shaft 1-10, cam 1-11, cam matching seat 1 -12, square column 1-13, spring 1-14, square column I1-15, spring I1-16, drawing pipe 1-17, water inlet pipe 1-18, water tank 1-19, threaded plug 1-20, connection Plate 1-21, slide valve 1-22, connection chamber 1-23, limit chute 1-24, wedge 1-25, spring II1-26, connecting rod 1-27, slide chamber 1-28, slide valve Moving chamber 1-29, piston 1-30, water outlet one-way valve 1-31, water inlet one-way va...

specific Embodiment approach 3

[0037] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 , Figure 16 Describe this embodiment, this embodiment will further explain the first embodiment, the frame mechanism 2 includes universal wheels 2-1, polished rod 2-2, return spring 2-3, vehicle body 2-4, limit post 2-5, connection limit plate 2-6, movable support platform 2-7, bearing seat 2-8, threaded hole 2-9, lead screw 2-10, chute 2-11, inner bearing seat 2-12, Pushing seat 2-13, shaft coupling 2-14, servo motor 2-15, universal wheel 2-1 links to each other with car body 2-4, polished rod 2-2 links to each other with car body 2-4, return spring 2-3 Set on the polished rod 2-2, the car body 2-4 links to each other with the limit column 2-5, the limit column 2-5 links to each other with the connection limit plate 2-6, and the movable support platform 2-7 lin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com