Ultrasonic fan flange bolt axial force monitoring system

A flange bolt, monitoring system technology, applied in force/torque/work measuring instruments, measuring devices, measuring torque/torsional force during tightening, etc. Problems such as inconvenient use of couplant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

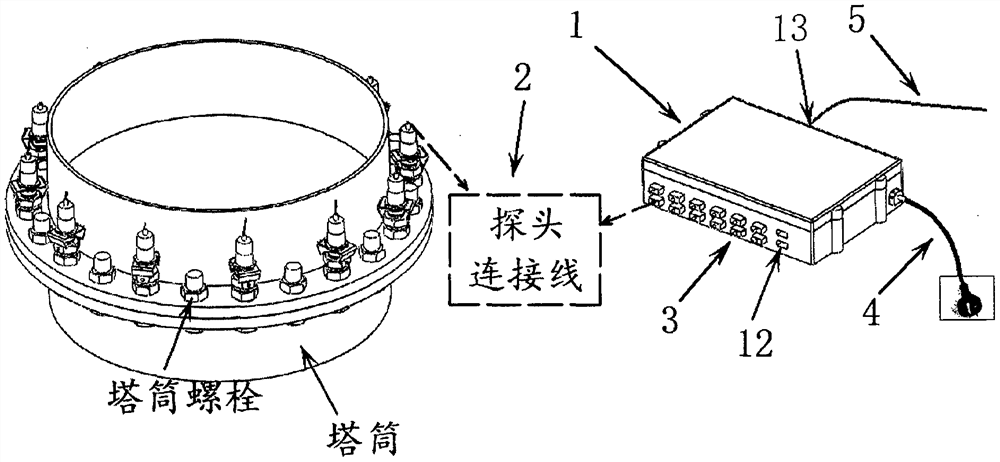

[0041] The present invention provides a convenient installation ultrasonic fan flange bolt axial force monitoring system based on the principle of acoustic elasticity. The structural principle and working principle of the present invention will be further described below in conjunction with the accompanying drawings.

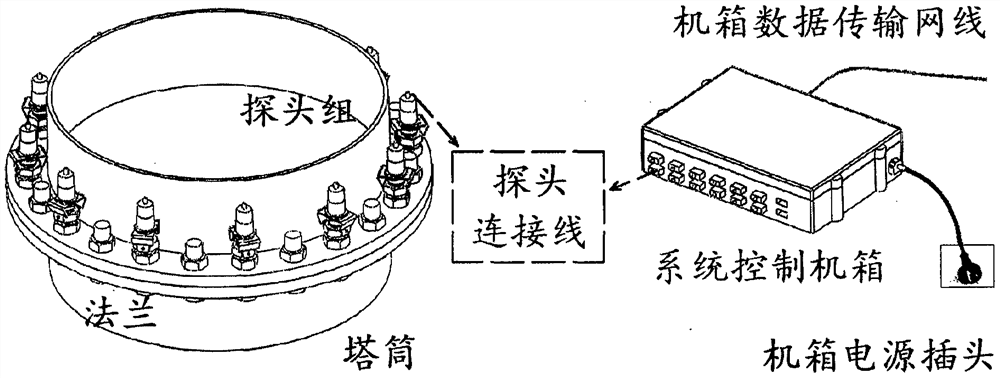

[0042] Such as figure 1 As shown, the system mainly includes an ultrasonic probe group, an ultrasonic probe connection line, a system control box, and a computer information processing software system.

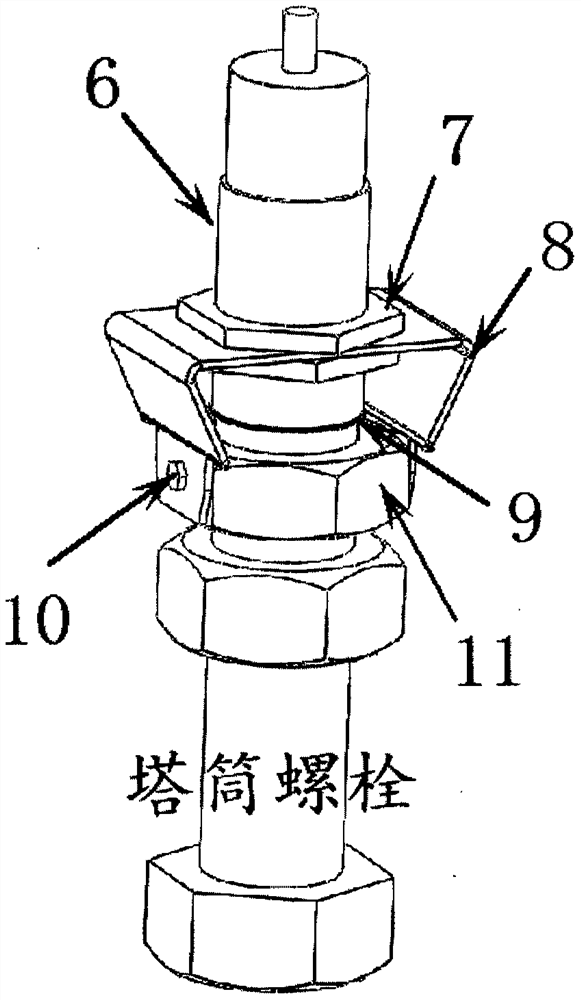

[0043] Such as figure 2 The ultrasonic probe 6 shown is fixed on the flange bolt of the fan, and the probe 6 is connected to the probe line interface 12 of the system control box 1 through the probe line 2. The system control box 1 is equipped with an ultrasonic pulse transmitting, receiving and filtering circuit, and the pulse transmitting circuit can be Transmitting pulses to the ultrasonic probe, the receiving circuit can receive ultrasonic reflected echoes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com