Fixing support of PLC (programmable logic controller)

A technology of programming controller and fixing bracket, applied in the direction of program control, electrical program control, digital control, etc., can solve the problems of parts detachment, strong inertial force and centrifugal force of the fixed bracket, etc., and achieve the effect of increasing friction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

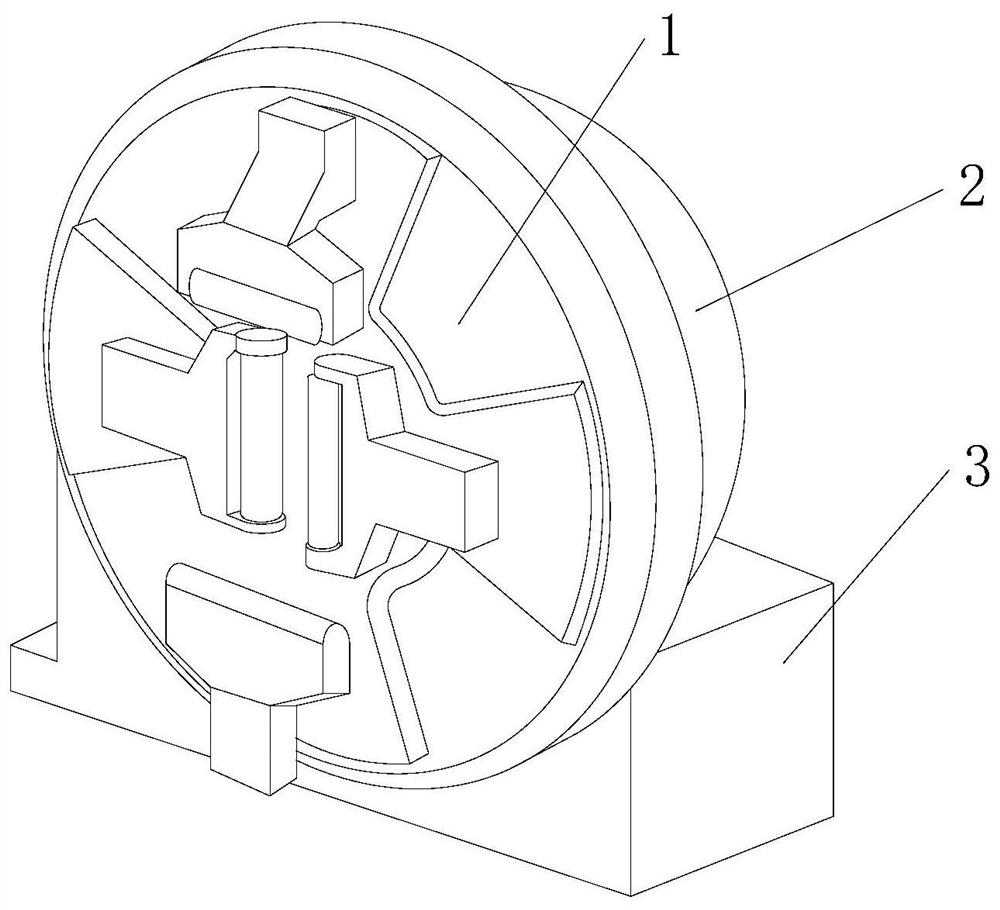

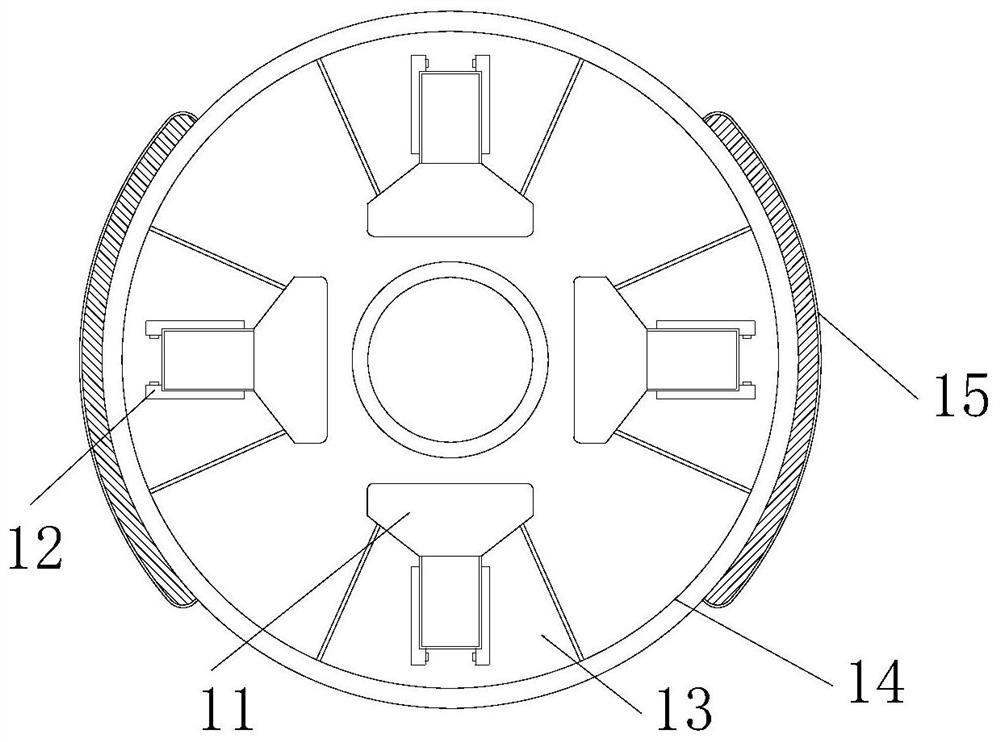

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The invention provides a fixed bracket for a PLC programmable controller, the structure of which includes a clamping device 1, a power disc 2, and a control base 3. The clamping device 1 is embedded and installed on the outer end surface of the power disc 2. The power The inlaid block on the lower end surface of the disc 2 is engaged with the control base 3, and the outer end surface of the control base 3 is connected to the clamping device 1; the clamping device 1 includes a clamping mechanism 11, a chute 12, an adjustment block 13, The fixed plate 14 and the embedded connecting strip 15, the clamping mechanism 11 is movably engaged with the inner end surface of the chute 12, the chute 12 is inlaid on the outer end surface of the adjustment block 13, and the adjustment block 13 is evenly embedded and installed On the upper surface of the clamping device 1 , the outer end surface of the fixed plate 14 is attache...

Embodiment 2

[0033] as attached Figure 6 to attach Figure 7 Shown:

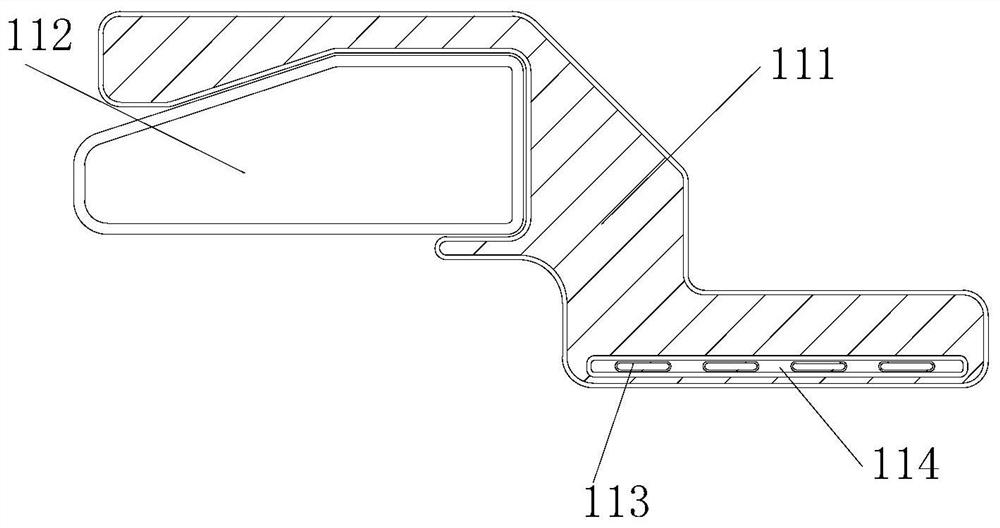

[0034]Wherein, the filling ball 221 includes a wrapping piece 211, a rectangular cavity 212, an adsorption mechanism 213, a rubber ball 214, and a half-arc piece 215. The cavity 212 is evenly arranged on the outer end surface of the wrapping sheet 211, the outer end surface of the adsorption mechanism 213 is attached to the rectangular cavity 212, the inner end surface of the rubber ball 214 is attached to the half-arc sheet 215, and the half-arc sheet 215 Located on the right side of the wrapping sheet 211 , the rubber ball 214 adopts a sandwich hollow design, which can cause corresponding deformation when being squeezed, and then expand outward along the rectangular cavity 212 .

[0035] Wherein, the adsorption mechanism 213 includes a bonding layer 131, an embedding plate 132, an air permeation hole 133, an arc block 134, and a rubber sheet 135. 132 is embedded with a rubber sheet 135 on the upper end surface. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com