Production process of low-glue-failure-rate light shoes

A production process and technology for lightweight shoes, which is applied in the field of production technology for lightweight shoes with a low glue-opening rate, can solve the problems of non-wear-resistant midsoles, low durability, and high cost, and achieve increased softness and comfort, simple overall process, and enhanced aesthetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

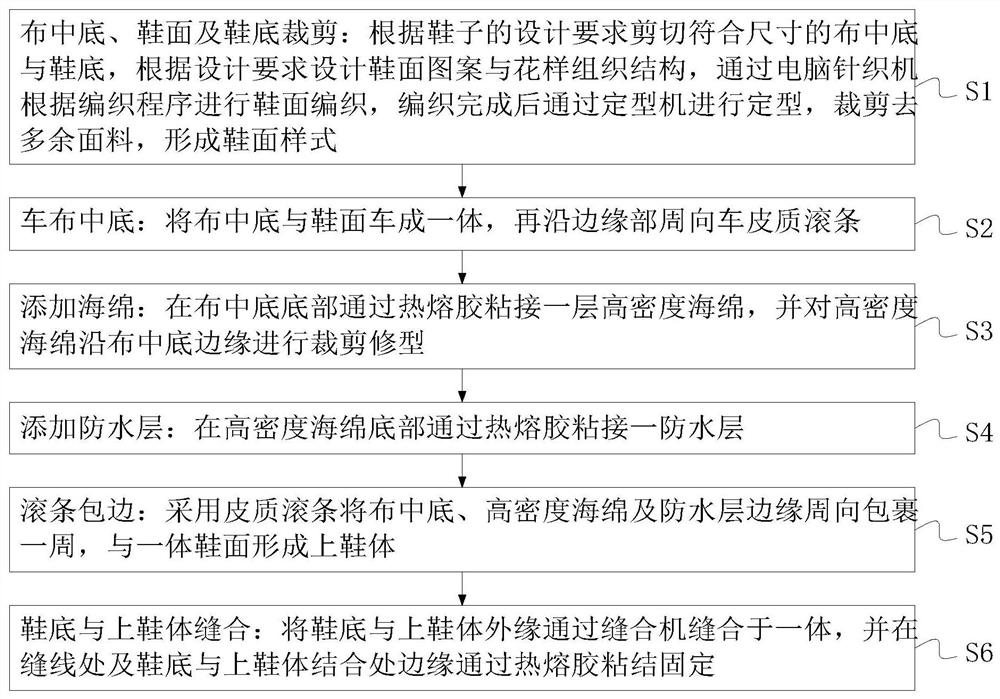

[0029] see figure 1 , the present invention provides the following technical solutions: a production process for light shoes with a low glue-opening rate, comprising the following preparation steps:

[0030] Step S1, cloth midsole, upper and sole cutting: Cut the cloth midsole and sole of the size according to the design requirements of the shoe, design the pattern and pattern structure of the upper according to the design requirements, and use the computer knitting machine to knit the shoe according to the knitting program. Surface weaving, after the weaving is completed, it is shaped by a setting machine, and the excess fabric is cut to form a shoe upper style;

[0031] Step S2, cloth midsole: integrate the cloth midsole with the shoe upper, and then roll the leather along the periphery;

[0032] Step S3, adding sponge: a layer of high-density sponge is bonded to the bottom of the cloth midsole with hot melt adhesive, and the high-density sponge is cut and trimmed along the...

Embodiment 2

[0046] see figure 1 , the present invention provides the following technical solutions: a production process for light shoes with a low glue-opening rate, comprising the following preparation steps:

[0047] Step S1, cloth midsole, upper and sole cutting: Cut the cloth midsole and sole of the size according to the design requirements of the shoe, design the upper pattern and pattern structure according to the design requirements, and use the computer knitting machine to knit the shoe according to the knitting program. Surface weaving, after the weaving is completed, it is shaped by a shaping machine, and the excess fabric is cut to form a shoe upper style;

[0048]Step S2, cloth midsole: integrate the cloth midsole with the shoe upper, and then roll the leather along the periphery;

[0049] Step S3, adding sponge: a layer of high-density sponge is bonded to the bottom of the cloth midsole with hot melt adhesive, and the high-density sponge is cut and trimmed along the edge of...

Embodiment 3

[0063] see figure 1 , the present invention provides the following technical solutions: a production process for light shoes with a low glue-opening rate, comprising the following preparation steps:

[0064] Step S1, cloth midsole, upper and sole cutting: Cut the cloth midsole and sole of the size according to the design requirements of the shoe, design the pattern and pattern structure of the upper according to the design requirements, and use the computer knitting machine to knit the shoe according to the knitting program. Surface weaving, after the weaving is completed, it is shaped by a setting machine, and the excess fabric is cut to form a shoe upper style;

[0065] Step S2, cloth midsole: integrate the cloth midsole with the shoe upper, and then roll the leather along the periphery;

[0066] Step S3, adding sponge: a layer of high-density sponge is bonded to the bottom of the cloth midsole with hot melt adhesive, and the high-density sponge is cut and trimmed along the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap