Cleaning and disinfecting equipment for small medical instruments

A technology for cleaning and disinfecting equipment, which is applied to sanitary equipment for toilets, disinfection, and water supply devices, etc. It can solve the problems of large manpower consumption, low cleaning efficiency, and long cleaning time, so as to reduce the burden, speed up cleaning and disinfection, and improve disinfection. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

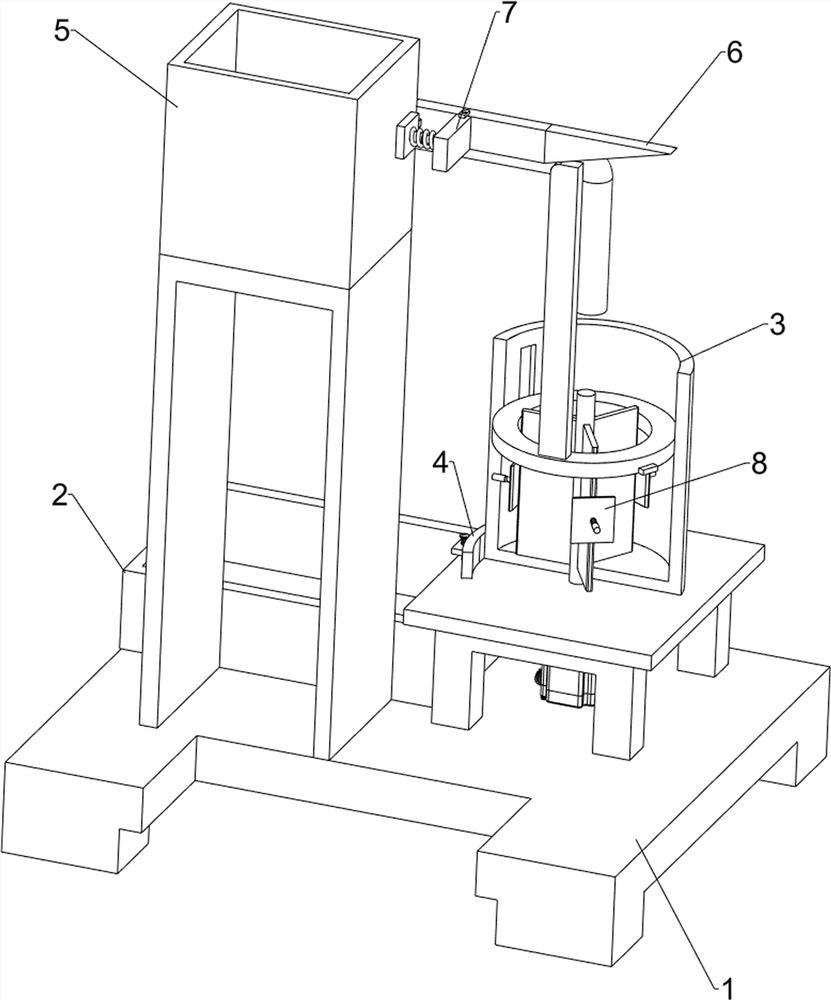

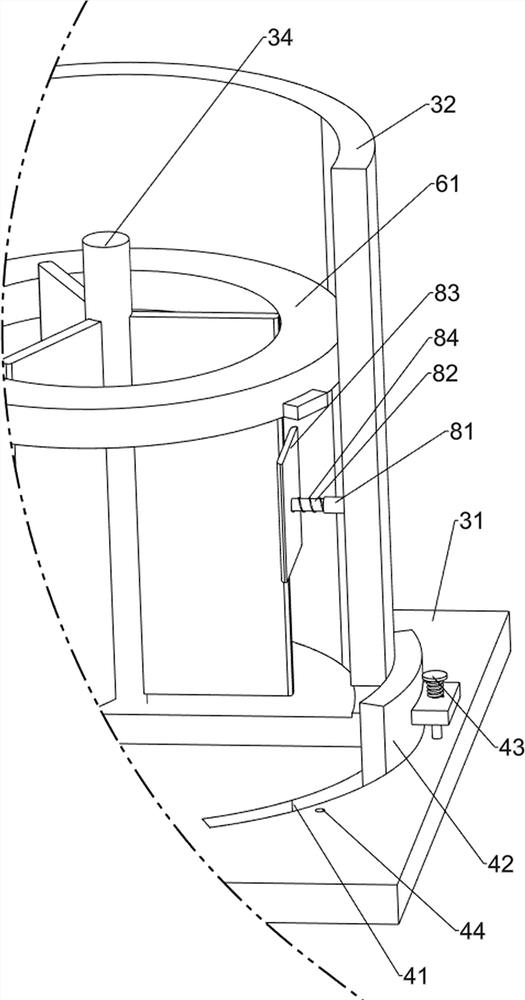

[0026] A kind of cleaning and disinfection equipment for small medical instruments, such as Figure 1-4 As shown, it includes a base plate 1, a water tank 2, a cleaning and stirring mechanism 3 and a liquid discharge mechanism 4. The front right side of the base plate 1 is provided with a water tank 2, and the front left side of the base plate 1 is provided with a cleaning and stirring mechanism 3. The right side of the stirring mechanism 3 is provided with a liquid discharge mechanism 4 .

[0027] When it is necessary to clean and disinfect small instruments, put the instruments into the cleaning and stirring mechanism 3, inject disinfectant into the cleaning and stirring mechanism 3, then start the cleaning and stirring mechanism 3, and the cleaning and stirring mechanism 3 will clean and disinfect the instruments. After completion, close the cleaning and stirring mechanism 3, then control the liquid discharge mechanism 4, and discharge the sterilized disinfectant into the w...

Embodiment 2

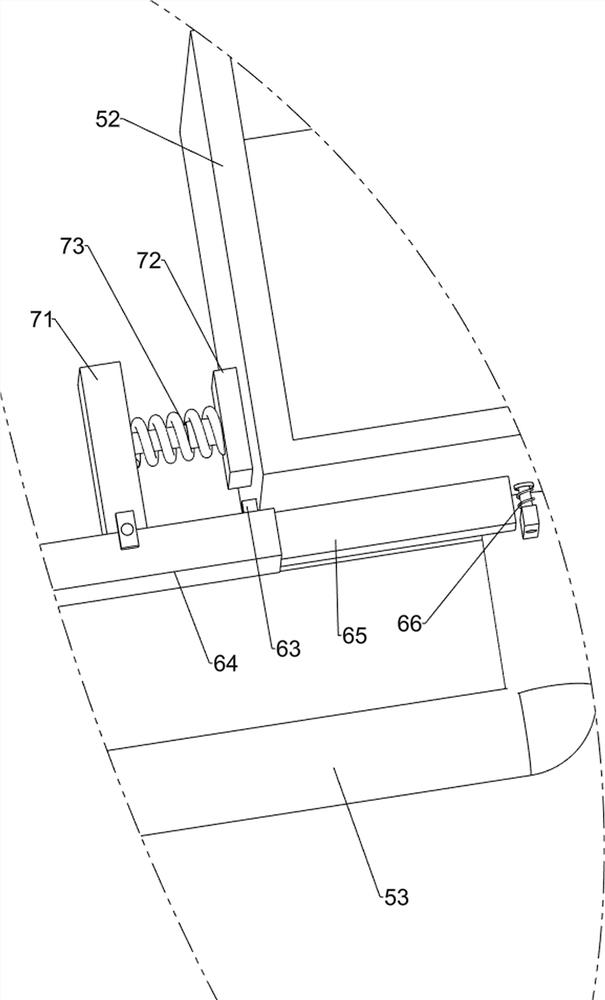

[0033] On the basis of Example 1, such as figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 As shown, a liquid guide mechanism 5 is also included, and the liquid guide mechanism 5 includes a second fixed frame 51, a liquid storage tank 52, a catheter 53, a second rotating shaft 54, a fixed block 55 and a second liquid baffle 56, and the bottom plate The upper side of 1 is connected with a second fixed frame 51, and the upper side of the second fixed frame 51 is provided with a liquid storage tank 52, and the front side of the liquid storage tank 52 is connected with a catheter 53, and the front side of the liquid storage tank 52 is rotatable. A second rotating shaft 54 is connected, the front side of the second rotating shaft 54 is connected with a fixed block 55 , and the rear side of the second rotating shaft 54 is welded with a second liquid baffle 56 , and the second liquid baffle 56 cooperates with the catheter tube 53 .

[0034] When it is necessary to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap