Gas purification device for paint drying equipment

A gas purification device and drying equipment technology, which is applied to the surface coating liquid device, mechanical equipment, chemical instruments and methods, etc., can solve the problems of high temperature, cumbersome operation, high cost, etc., and achieve the effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments.

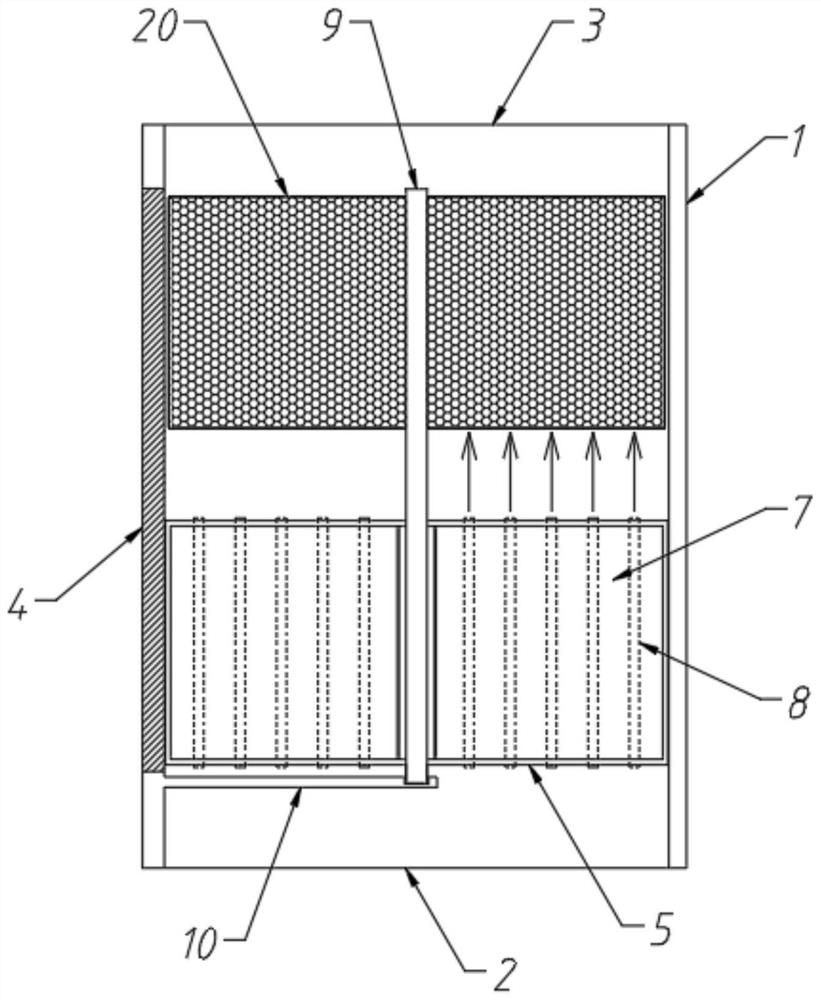

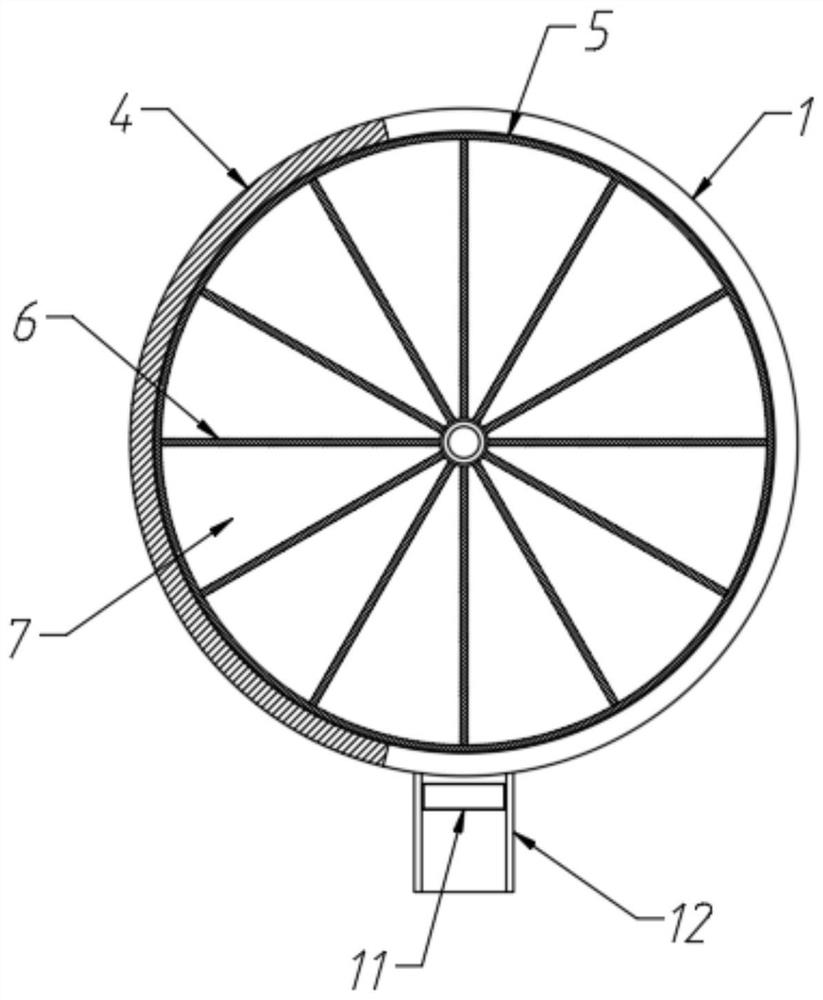

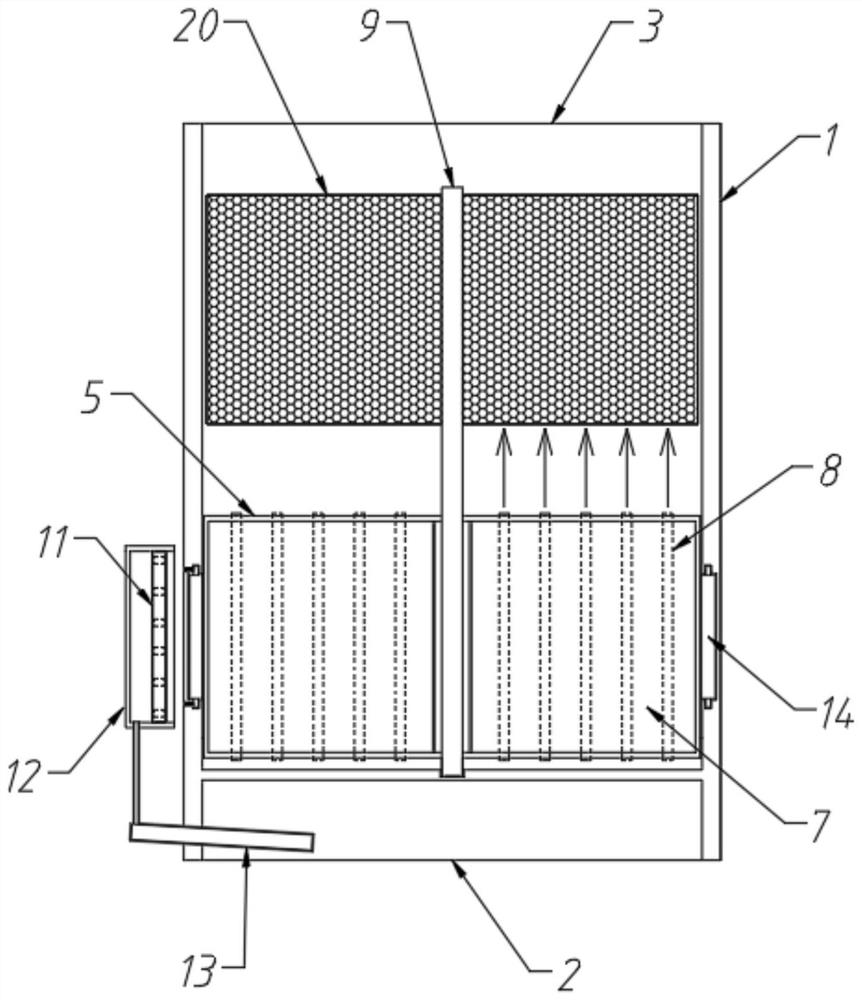

[0024] refer to Figure 1-5 , a gas purification device for paint drying equipment, comprising:

[0025] Cylindrical shell 1, one end of the shell 1 is the inlet end 2, the other end is the outlet end 3, one side of the shell 1 is the heat-conducting area 4, and the other parts are the non-heat-conducting area 4. Thermal zone 4 is made of materials with better thermal conductivity;

[0026] The rotating cylinder 5 is rotated and arranged in the casing 1 through the rotating shaft 9, and is close to the intake end 2. The rotating shaft 9 is located on the axis of the casing 1. The interior of the rotating cylinder 5 is divided by a pluralit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com