Metal plate stamping arc-shaped die

An arc and die technology, applied in the field of stamping die, can solve the problems of positional deviation between the plate and the upper surface of the lower die, and can not be automatically removed, and achieve the effect of reducing labor consumption, increasing efficiency, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

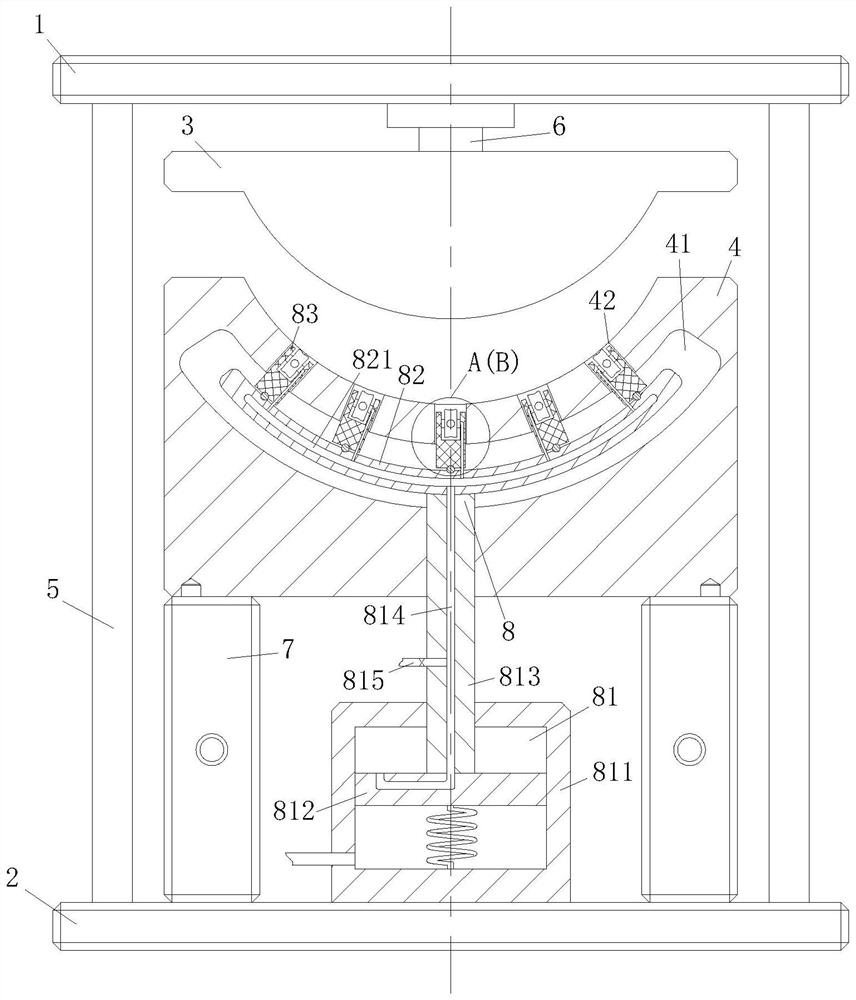

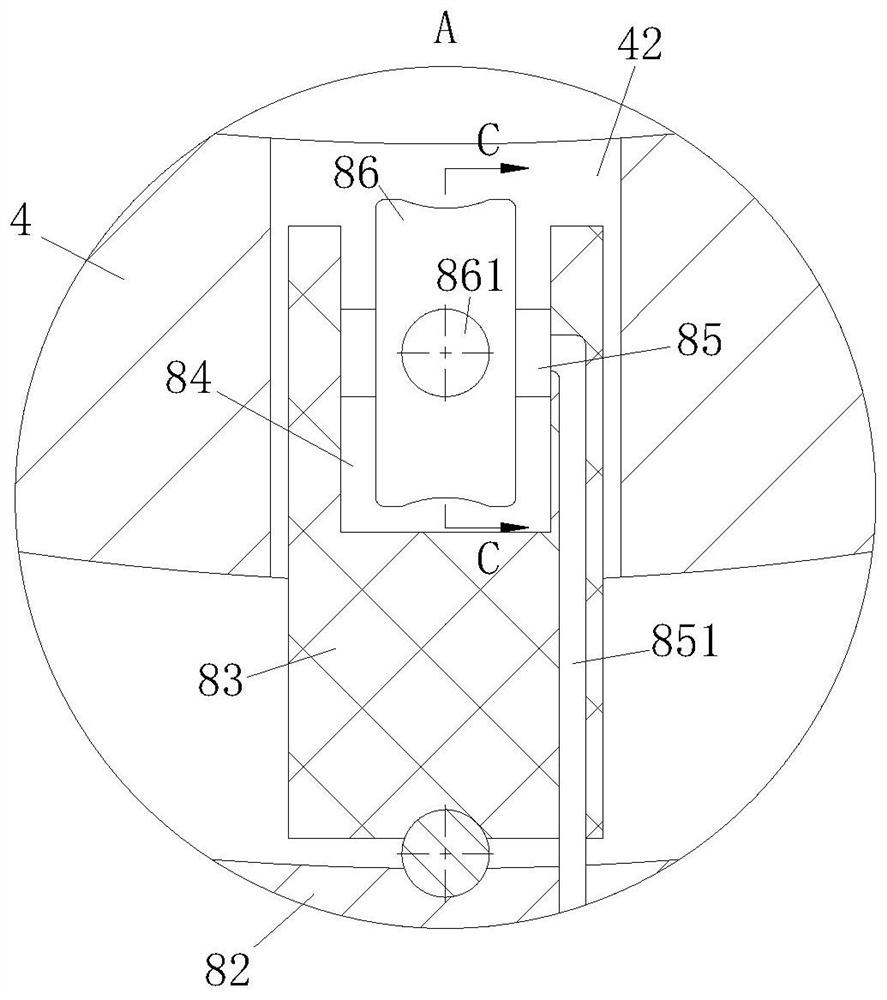

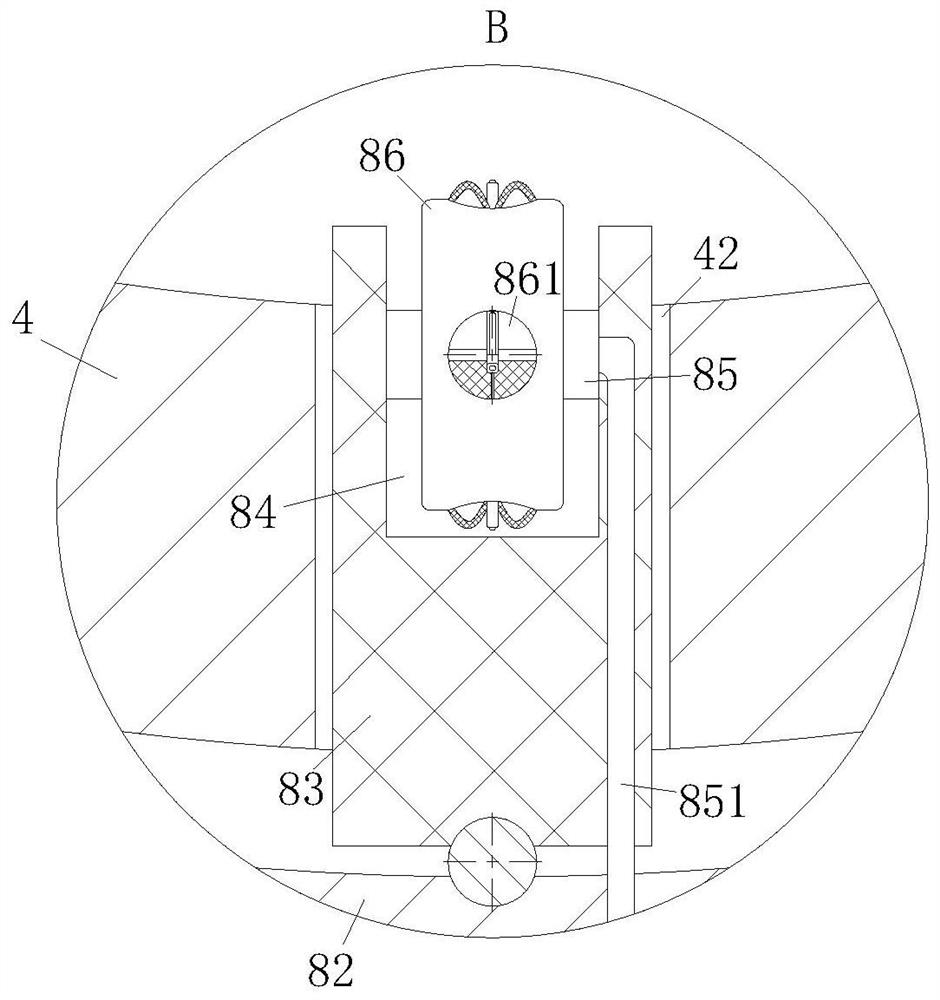

[0034] As a specific embodiment of the present invention, the No. 2 cylinder 81 is composed of a cylinder body 811, a piston plate 812 and a piston rod 813; the cylinder body 811 is installed on the lower base plate 2; Inside, the lower surface of the piston plate 812 is fixedly connected with the inner wall of the cylinder body 811 through a spring, and the upper surface of the piston plate 812 is connected with a piston rod 813; A channel 814 is opened on the top; one end of the channel 814 communicates with the area formed by the cylinder body 811 and the upper surface of the piston plate 812, and the other end communicates with the No. 2 cavity 821 provided in the arc-shaped push plate 82, and the channel 814 passes through The No. 1 hose 815 of the one-way valve communicates with the external air source; each hollow shaft 85 communicates with the No. 2 cavity 821 through the No. 2 hose 851; each runner 86 is provided with a set of ejector holes 861, and each ejector hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com