Industrial robot disordered grabbing method based on double-clamp real-time switching

A technology of industrial robots and double grippers, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve problems such as potential safety hazards, reduced production efficiency, and low grasping success rate, so as to avoid collisions, ensure stability, and improve flexibility. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only used to illustrate the present invention, and should not be considered as limiting the scope of the present invention.

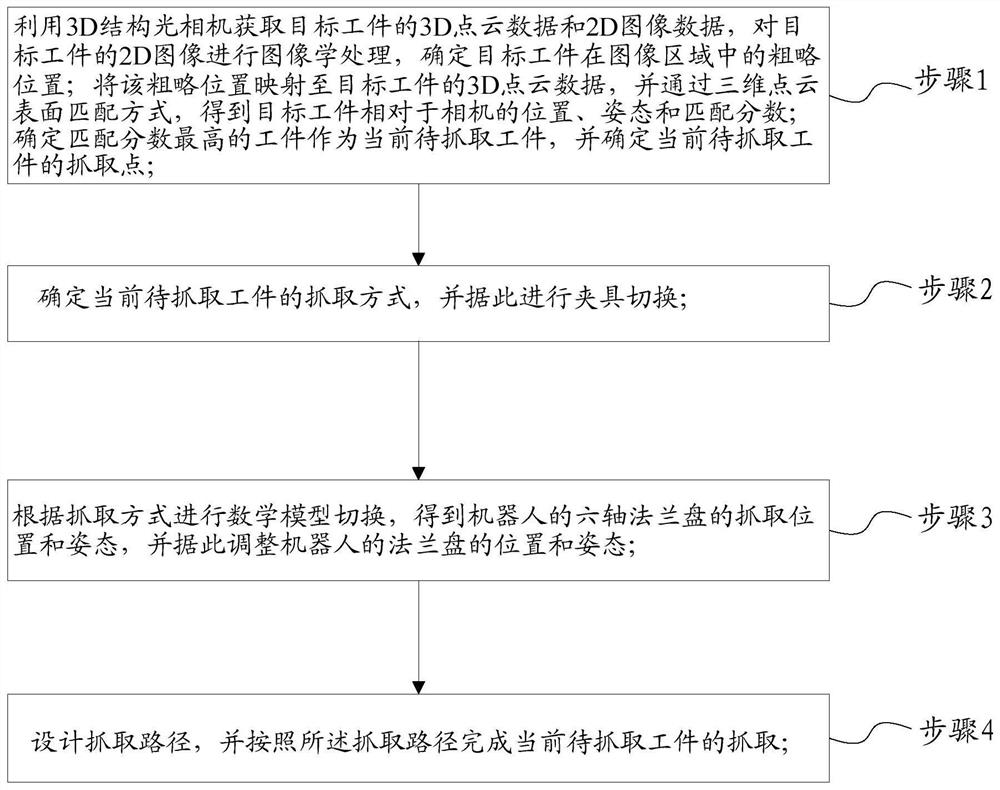

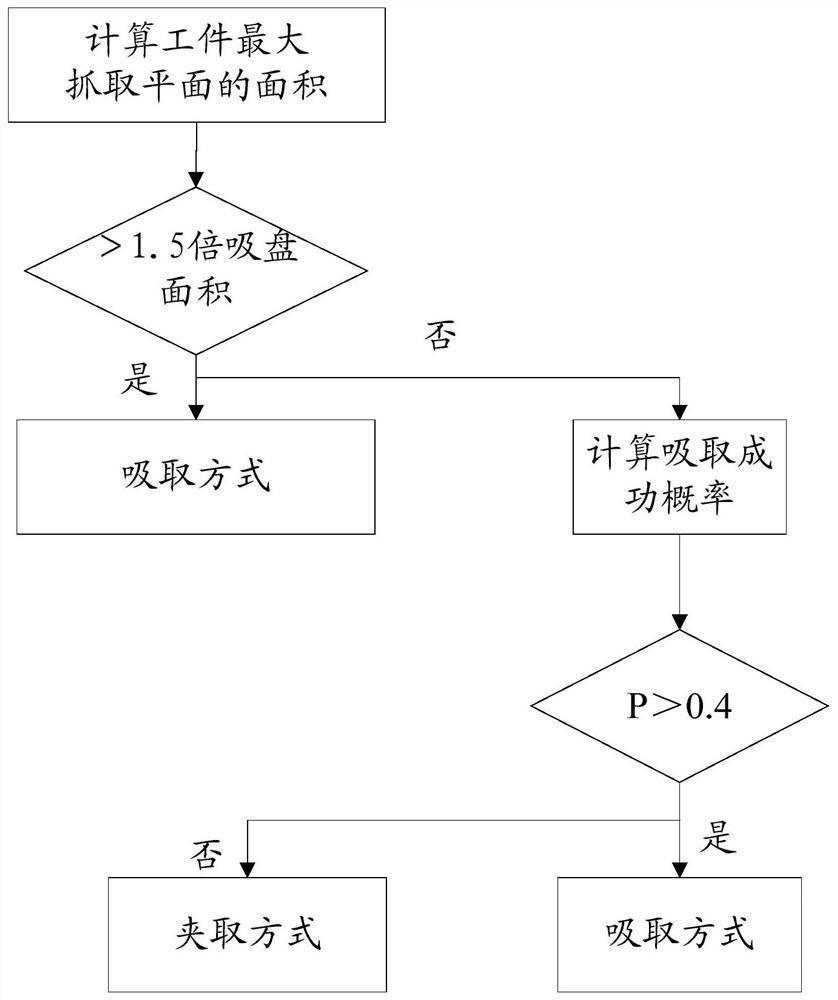

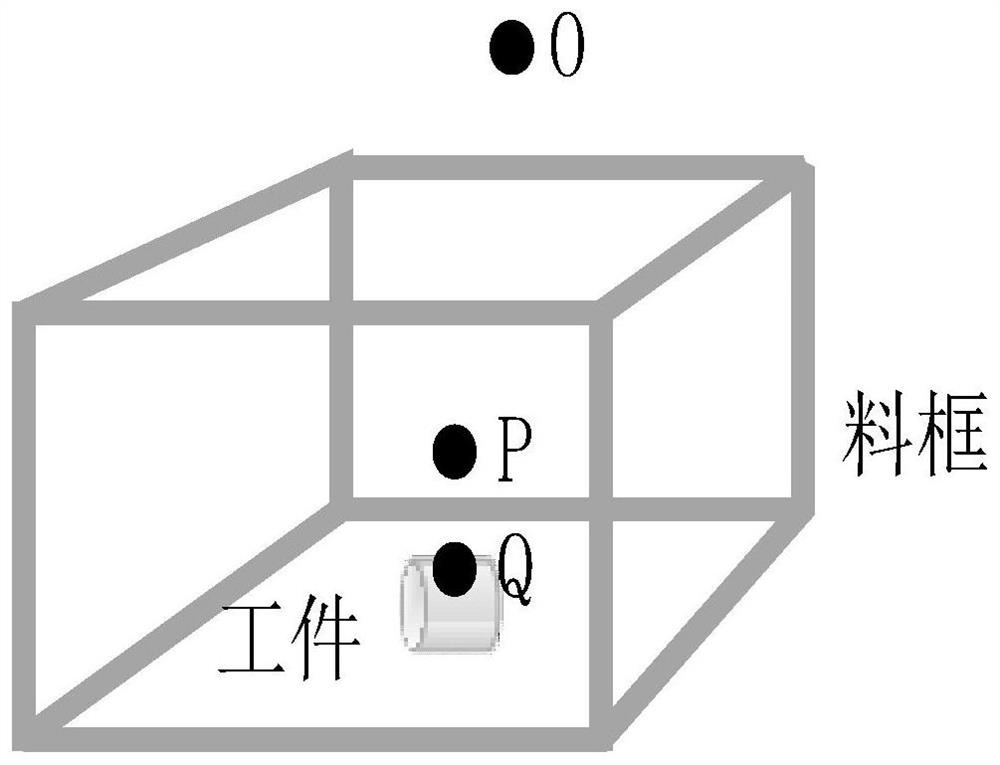

[0046] refer to figure 1, the present invention provides a disorderly grasping method for an industrial robot based on double-clamp real-time switching, the robot is a six-axis robot with a six-axis flange, and a tool is installed on the six-axis flange, and the tool includes Suction cups and grippers are two kinds of fixtures. In this embodiment, the robot is a mechanical arm, and the end of the mechanical arm is a tool. The tool includes two independent grabbing tools, and each grabbing tool has a telescopic actuator and Clamps at its ends, i.e. suction cups and grippers.

[0047] The fetching method includes the following steps:

[0048] Step 1: Use the 3D structured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com