Homogenizing equipment for thermoplastic elastomer hand feeling pre-dispersed master batches

A technology of thermoplastic elasticity and body feel, which is applied in the direction of mechanical equipment, spring/shock absorber, vibration suppression adjustment, etc., can solve the problems that the pre-dispersed masterbatch cannot be mixed evenly, the quality of mixing is reduced, and it is inconvenient to clean, etc., to achieve saving and mixing cost, work load reduction, burden reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

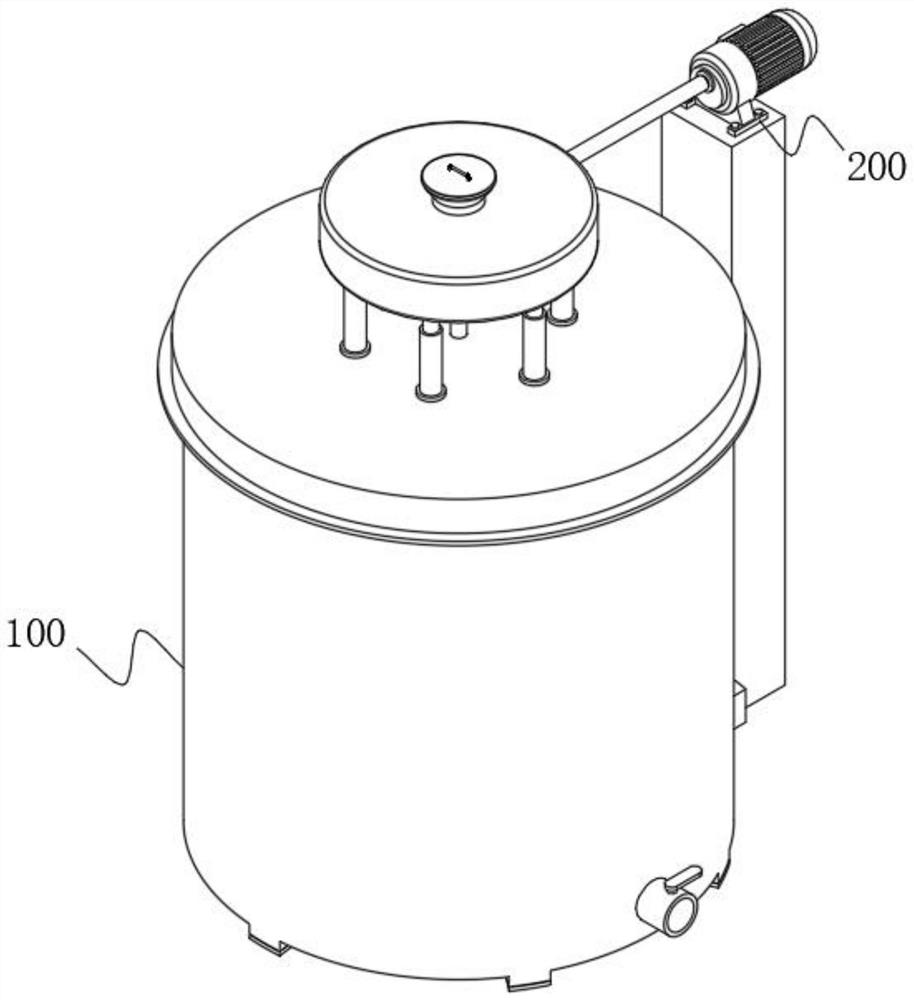

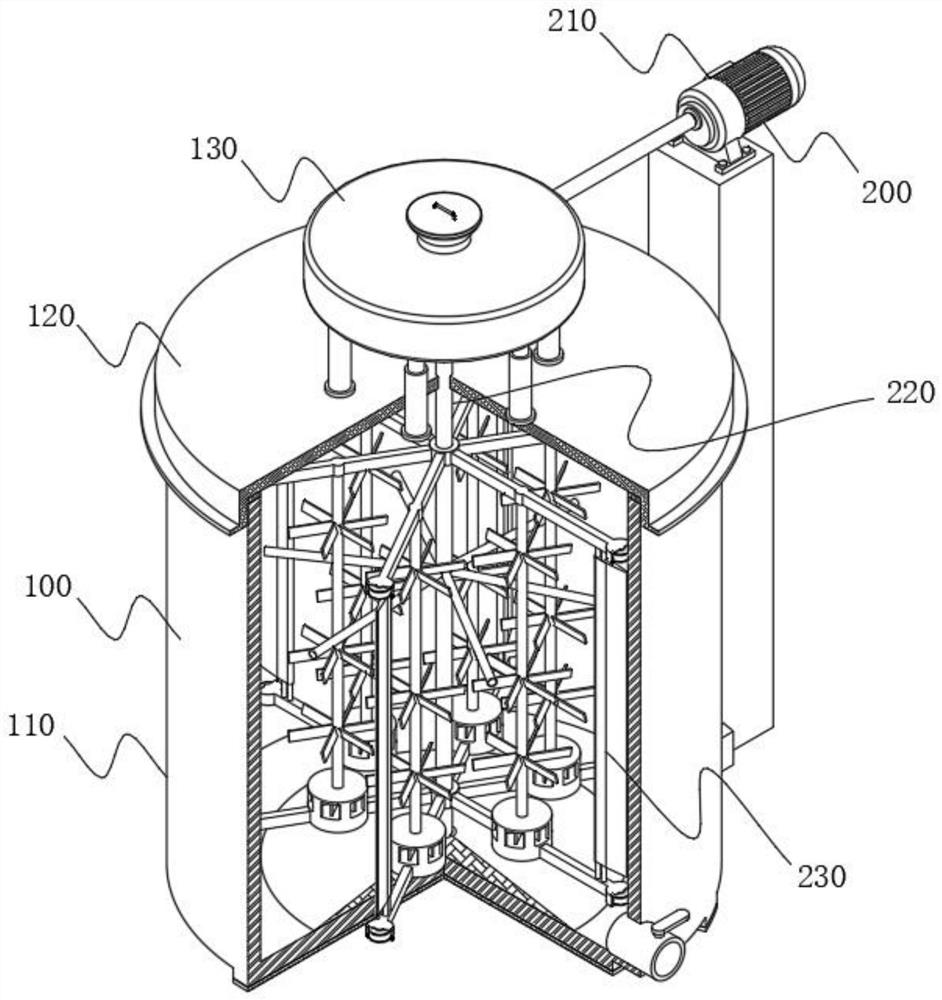

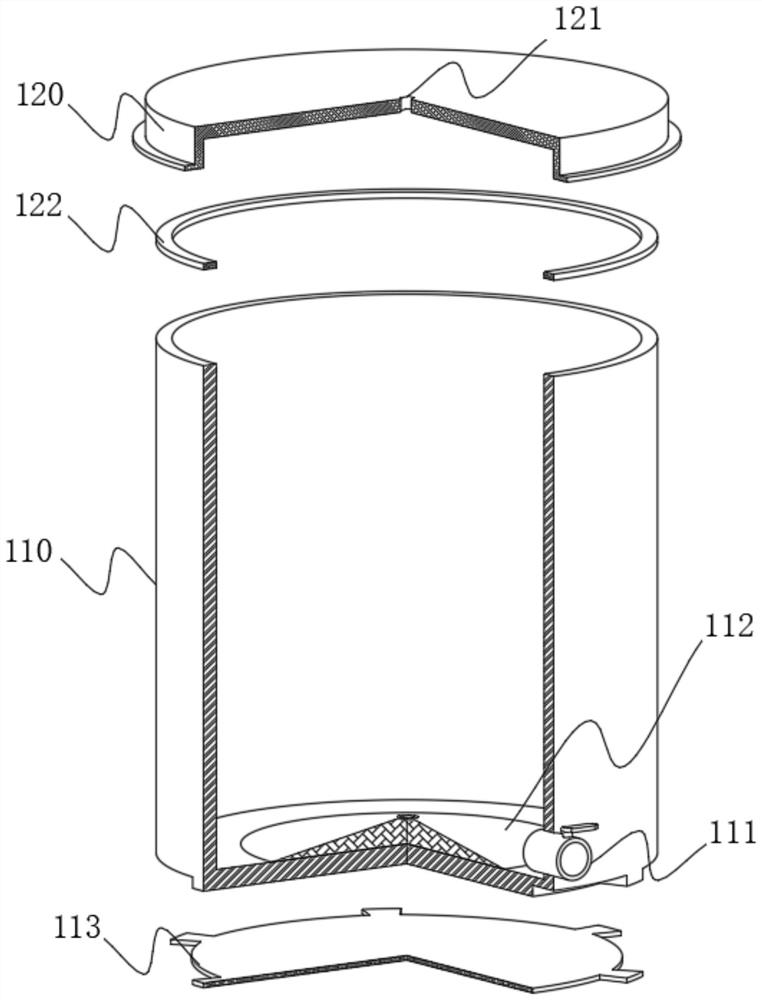

[0068] The invention provides a kind of mixing equipment for thermoplastic elastomer feel pre-dispersed masterbatch, please refer to Figure 1-Figure 15 , including an outer box 100 and a leveling device 200, the outer box 100 includes a box body 110, the top of the box body 110 is provided with a box cover 120, which plays a role in sealing the top of the box body 110, and the center of the box cover 120 is provided with a through hole 121, the inside of the box body 110 is provided with a cavity, the bottom end of the box body 110 is provided with a connecting base 112, the bottom of the front side of the box body 110 is provided with a discharge pipe 111, and the top of the discharge pipe 111 is provided with a control valve. The working principle of the stop valve is well known to those skilled in the art. Depending on the pressure of the valve rod, the sealing surface of the valve disc and the sealing surface of the valve seat are closely attached to prevent the flow of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com