Injection mold

A technology of injection mold and mold bottom plate, which is applied in the direction of coating, etc., can solve the problems of reducing the impact force of molten material, increasing the injection cycle, floating, etc., and achieve the effect of improving production pass rate and increasing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention will be further described below with reference to the accompanying drawings and specific examples.

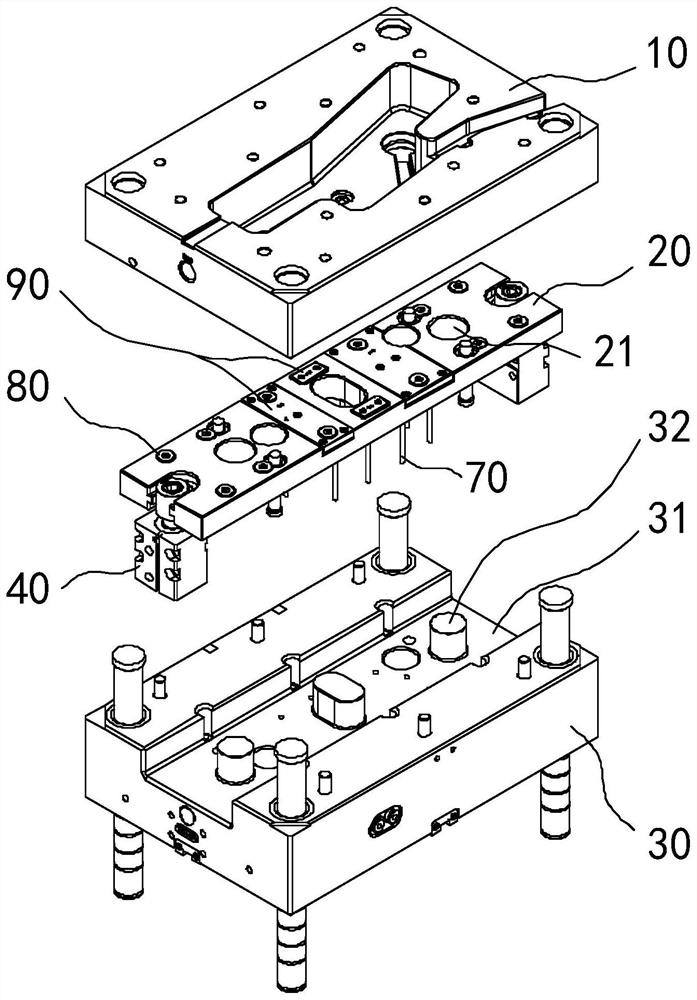

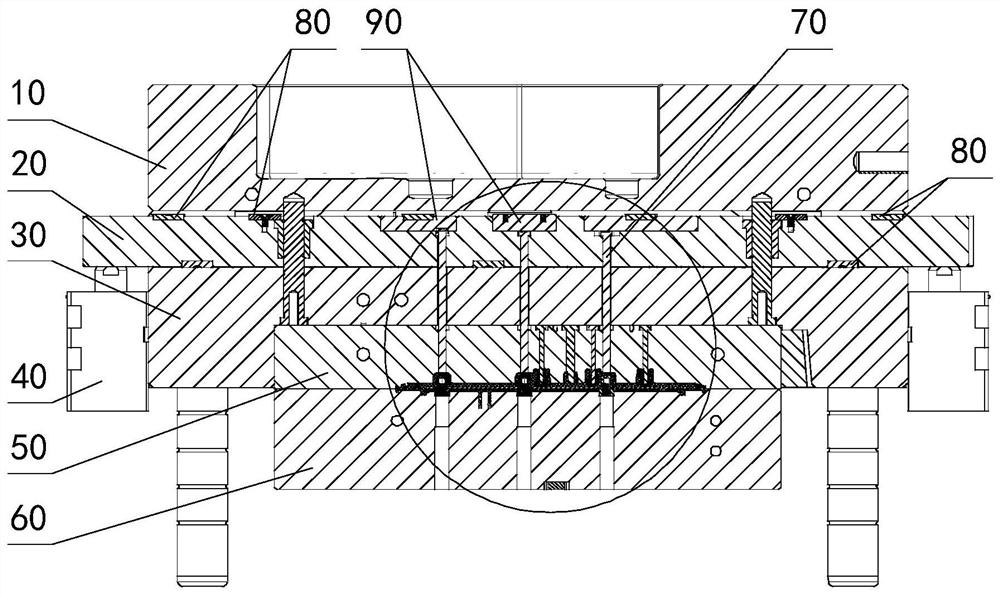

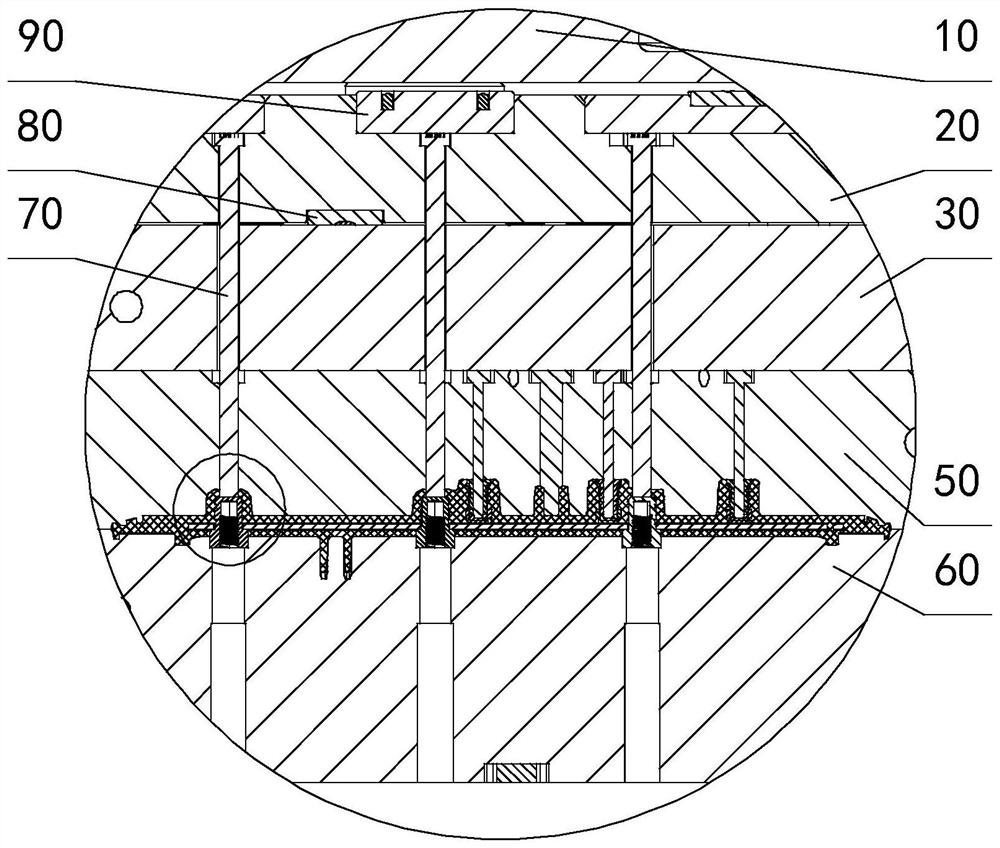

[0021]Example, referring toFigure 1-6 , An injection mold, including upper mold bottom plate 10, upper mold fixing plate 30, upper film 50, lower film 60, hydraulic cylinder 40, limit pin fixing plate 20, limit pin 70, limited pin cover 90 The upper mold fixing plate 30 is fixed to the upper mold bottom plate 10 and the upper film 50, respectively; the top surface of the upper mold fixing plate 30 has a plate groove 31 that penetrates both ends and can place a limit pin fixing plate 20, and the groove 31 The depth is greater than the height of the limit pin fixing plate 20; the limit pin fixing plate 20 is mounted in the groove 31, and the bottom surface of the groove 31 has several positioning columns 32, and the limit pin fixing plate 20 has several positioning posts 32. The hole 21, the rear limit pin fixing plate 20 can only be moved up and down in the gr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap